Concentric winding field coil making tool

A technology of excitation coils and concentric windings, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, etc., can solve the problems of difficult forming of the end of the excitation coil of concentric windings, and achieve easy shaping of the ends, regular forming, and embedding of wires high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

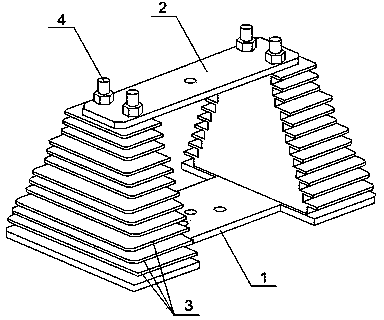

[0015] Such as figure 1 As shown, a concentric winding excitation coil manufacturing tooling includes a lower plate 1 and an upper plate 2, two stacks of coils 3 are arranged symmetrically at both ends between the two plates, and two bolts and nuts 4 are used to connect the lower plate from bottom to top. The plate 1, the coil 3 and the upper plate 2 are fastened, and each coil 3 is divided into three coil layers, the length of these three coil layers is the same, and the width dimension changes in steps.

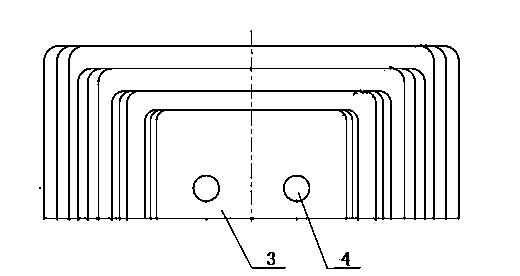

[0016] In this embodiment, the width of each coil layer of each stack of coils 3 becomes shorter successively from bottom to top, as figure 2 shown.

[0017] Each stack of coils 3 is composed of four coils.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com