Superconducting air vacuum tube

A vacuum tube and air technology, which is applied in the field of solar energy, can solve the problems of reducing the heat absorption of the heat absorption tube, difficult sealing, and long heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

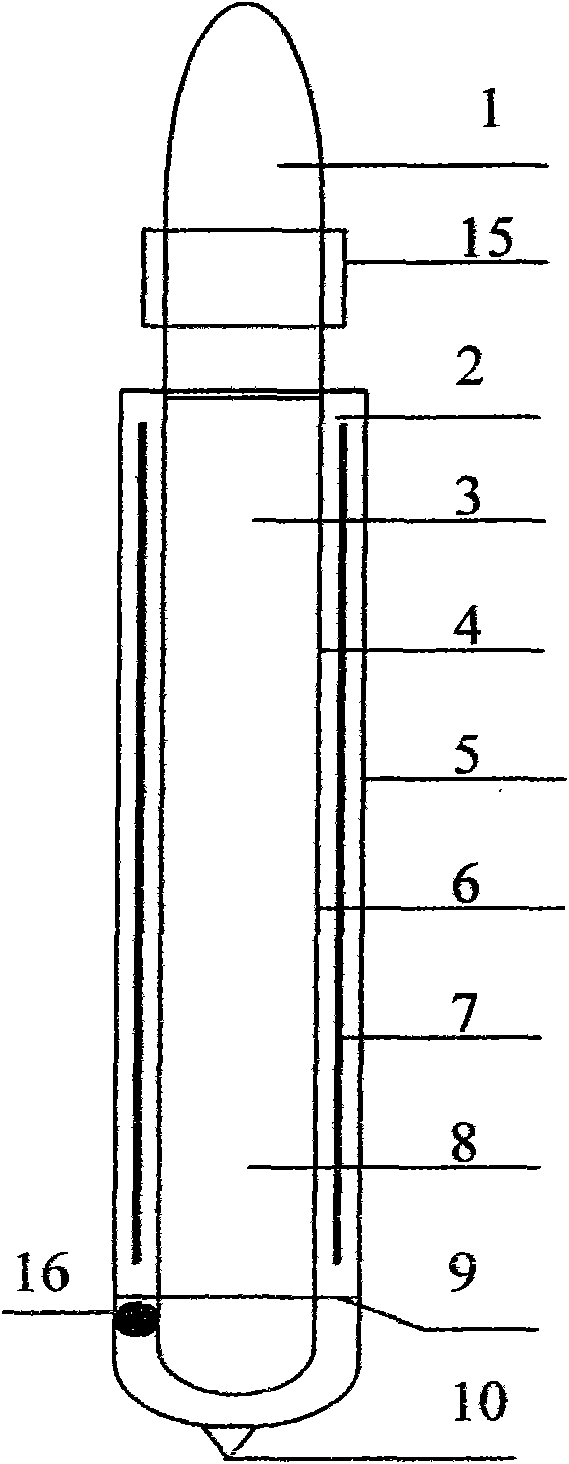

[0008] In specific embodiment 1, the condensation end (1) of the superconducting air vacuum tube is connected to the power generation module (15), the vacuum tube (2) is connected to the superconducting air vacuum tube (3), and the inner glass tube (4) is connected to the outer glass tube (5). ) Is connected at one end, the heat-absorbing coating (6) is applied to the surface of the inner glass tube (4), and the built-in condensing reflector (7) is installed between the inner and outer glass tubes (4, 5) and close to the outer glass tube On one side of (5), the spring bracket ((9), getter (16) and the outer glass tube (5) bridge the middle bottom of the inner glass tube (4), and one end of the outer glass tube (5) is welded to the vacuum sealing nozzle (16) , The heat-conducting air (8) is sealed in the superconducting air vacuum tube (3).

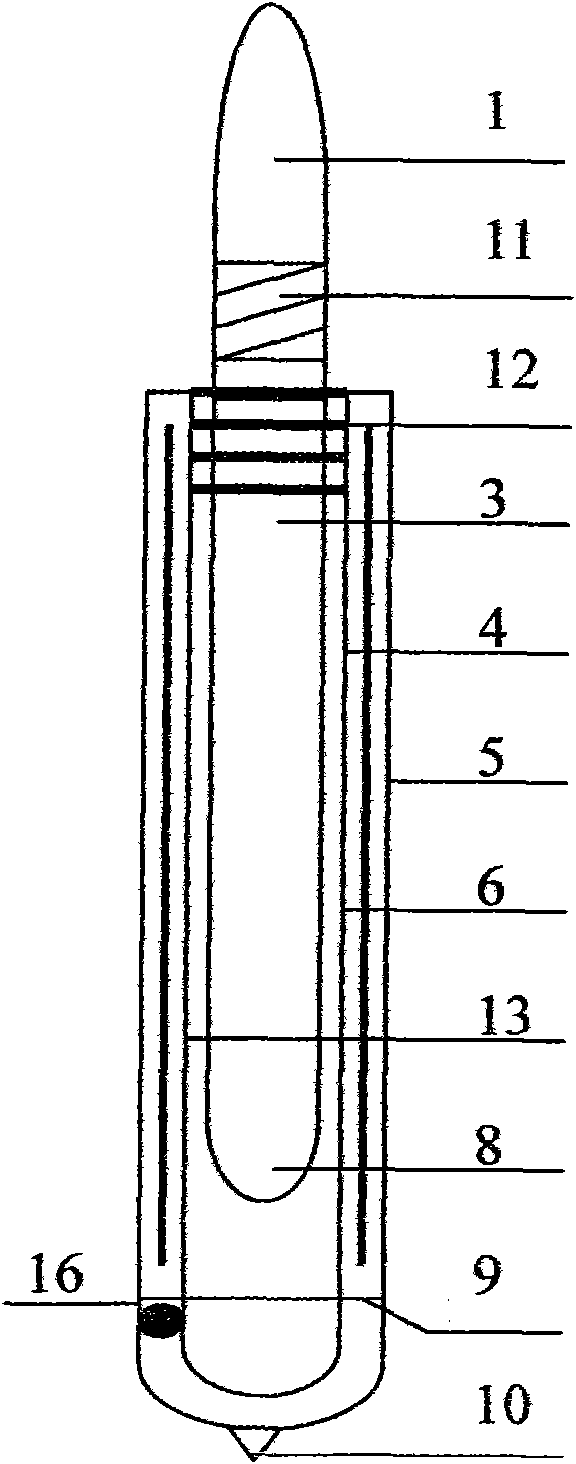

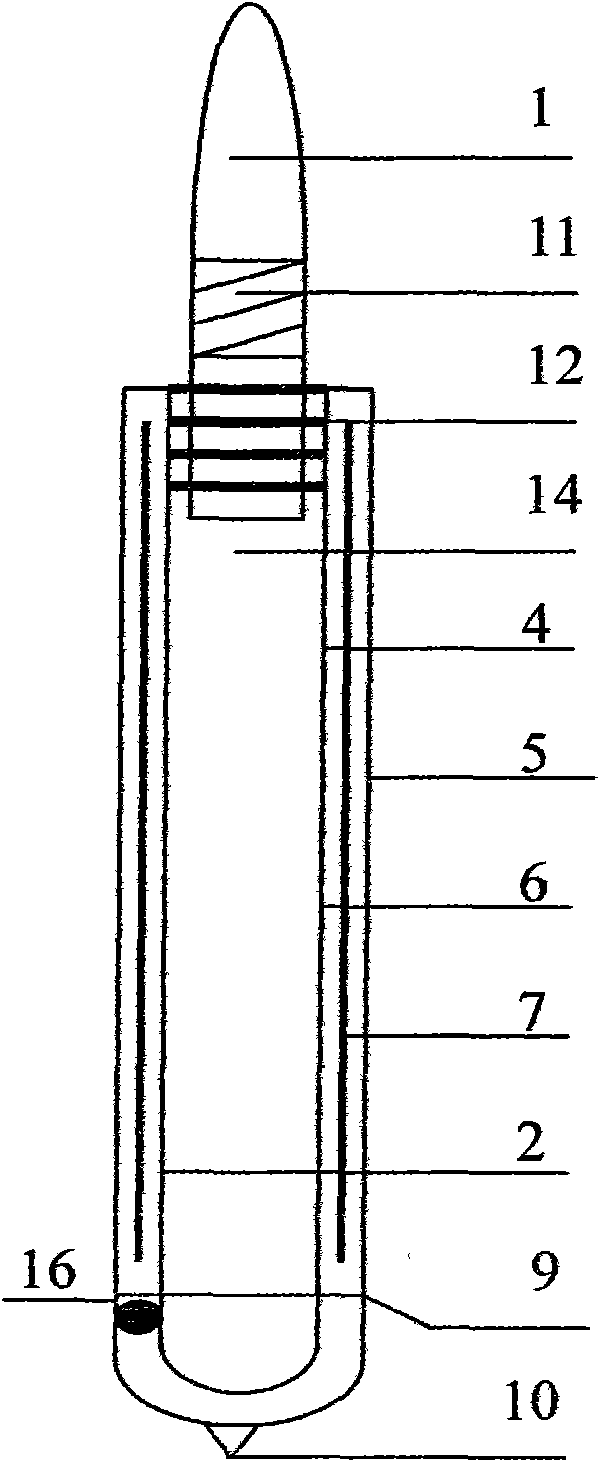

[0009] In the specific embodiment 2, the superconducting air vacuum tube (3) and the inner tube of the vacuum tube (2) are connected through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com