A transformer winding temperature measuring device

A technology for transformer windings and temperature measuring devices, which is applied to measuring devices, thermometers and instruments with physical/chemical changes, etc., can solve the problem that the winding temperature cannot be effectively measured, and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

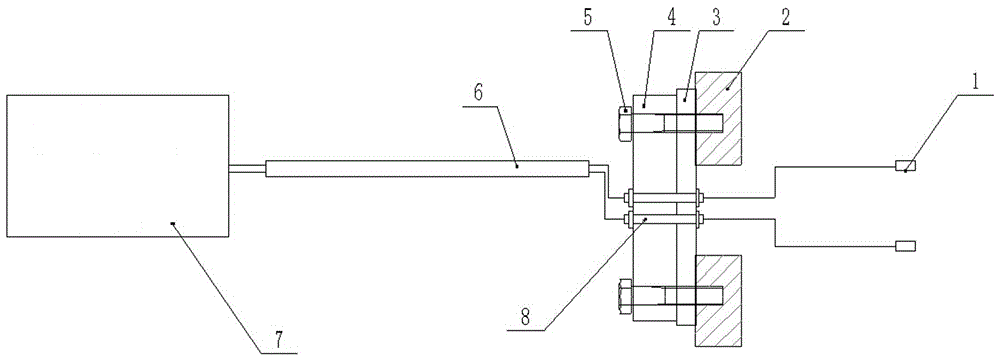

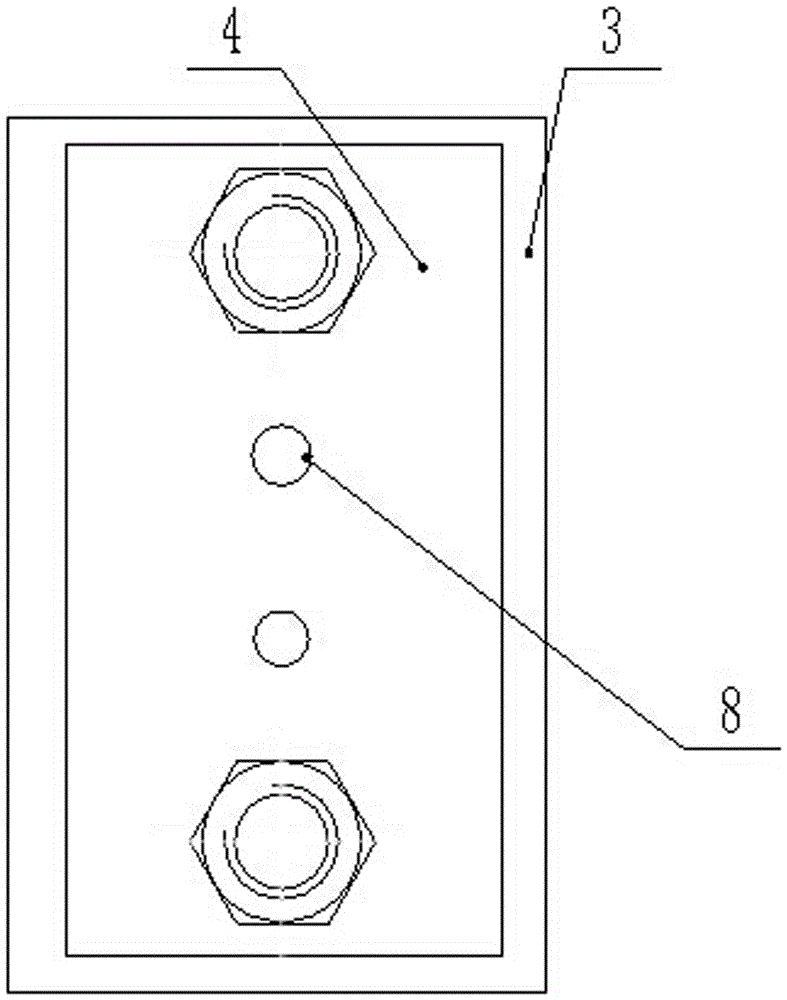

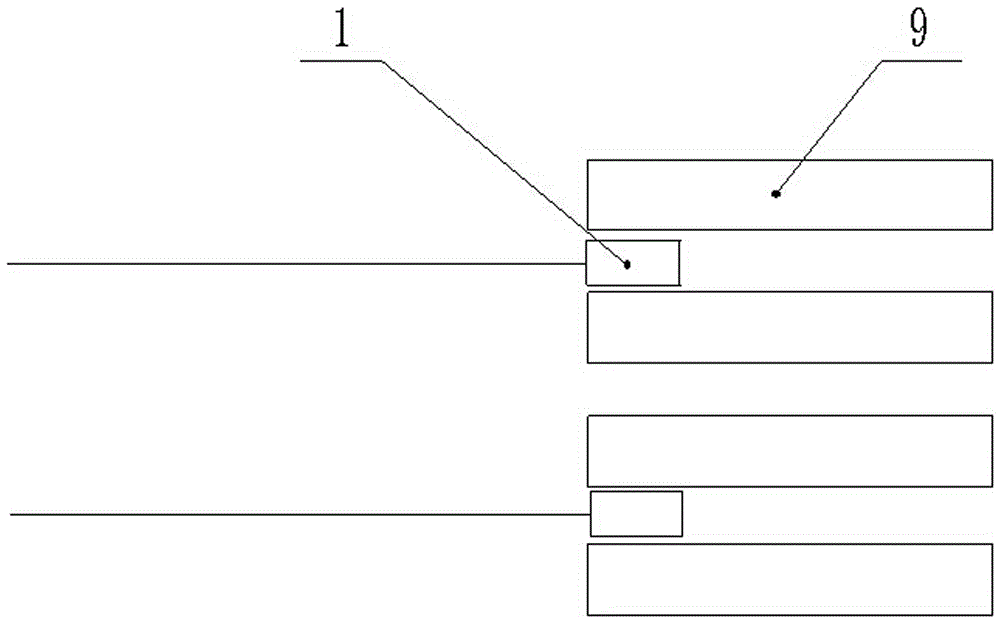

[0014] A transformer winding temperature measurement device, comprising an interface board 4 fixed on the transformer box 2, a fiber grating temperature sensor 1 and a fiber grating demodulator 7 embedded between the inner windings 9 of the transformer, and the board surface of the interface board 4 The optical fiber connector 8 is also fixed on the optical fiber grating temperature sensor 1. The optical fiber connector joint on the end of the optical fiber grating temperature sensor 1 extends out of the transformer box 2 and is connected to one end of the optical fiber connector 8 on the interface board 4. The optical fiber grating demodulator 7 passes The optical fiber 6 is connected to the other end of the optical fiber connector 8 on the interface board 4.

[0015] In the above-mentioned transformer winding temperature measurement device, a sealing ring 3 is also cushioned between the interface board 4 and the transformer box 2.

[0016] In the above-mentioned transformer windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com