A compressed gas arc extinguishing device and a high-voltage circuit breaker using the arc extinguishing device

An arc-extinguishing device and cylinder-pressing technology, which is applied to high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc. Longevity, ease of manufacture and assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

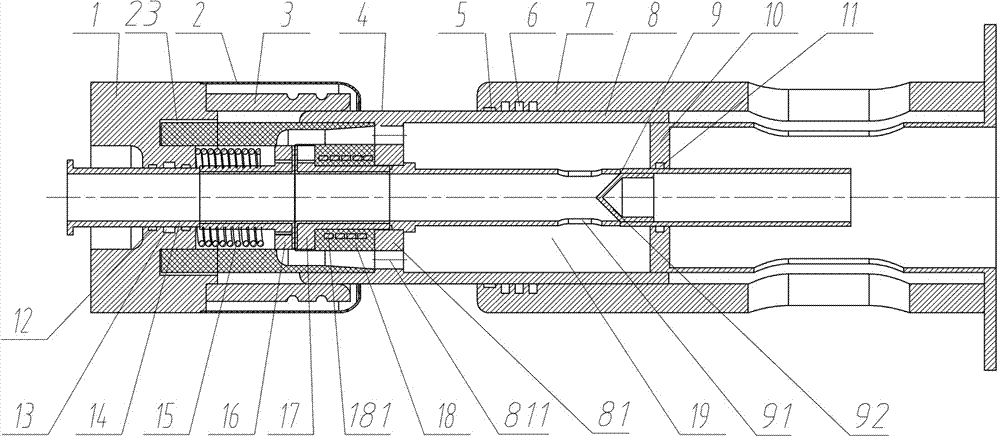

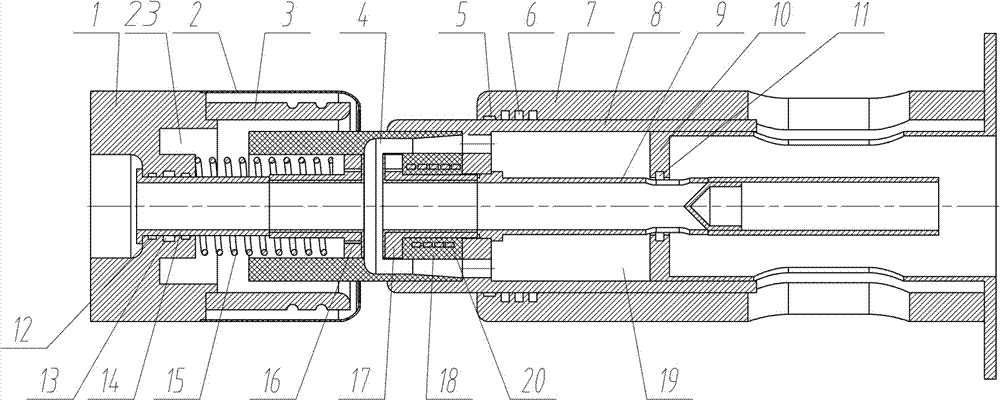

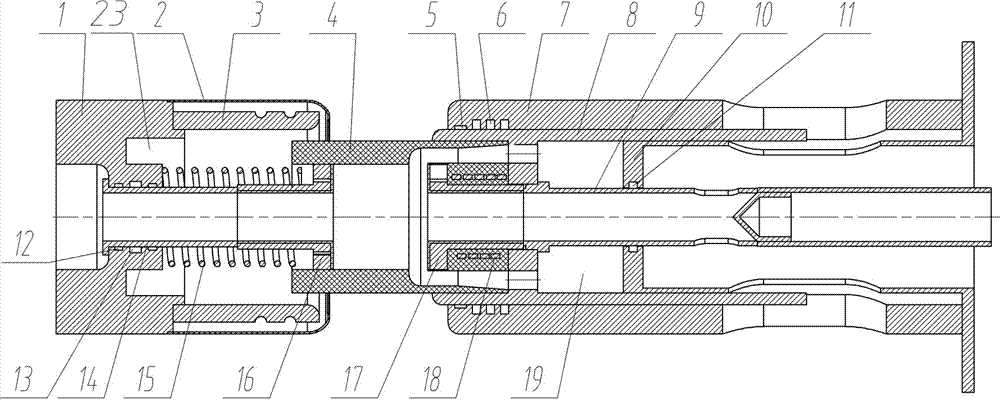

[0024] An embodiment of a compressed gas arc extinguishing device in the present invention is as follows Figure 1~Figure 6 shown, is a SF 6 The arc extinguishing chamber includes a static end assembly and a moving end assembly, wherein the static end assembly includes a static contact seat 1, a static end shield 2, a static main contact 3 and a static arc contact 16, and the moving end assembly includes a moving end conductor 7, The support base 10 and the pressure cylinder 8, nozzle 4, moving arc contact 17 and pull rod 9 fixedly assembled together, the end of the pressure cylinder 8 close to the static end assembly constitutes the moving main contact for conducting with the static main contact 3 head.

[0025]The assembling method of the static contact seat 1 , the static end shield 2 and the static main contact 3 is the prior art, and will not be described in detail here. The static arc contact 16 includes a contact cylinder 21 with an axial through hole, and a flange ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com