Bursting element and galvanic cell with bursting element

A technology of primary batteries and components, applied in the direction of electrical components, secondary batteries, battery components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

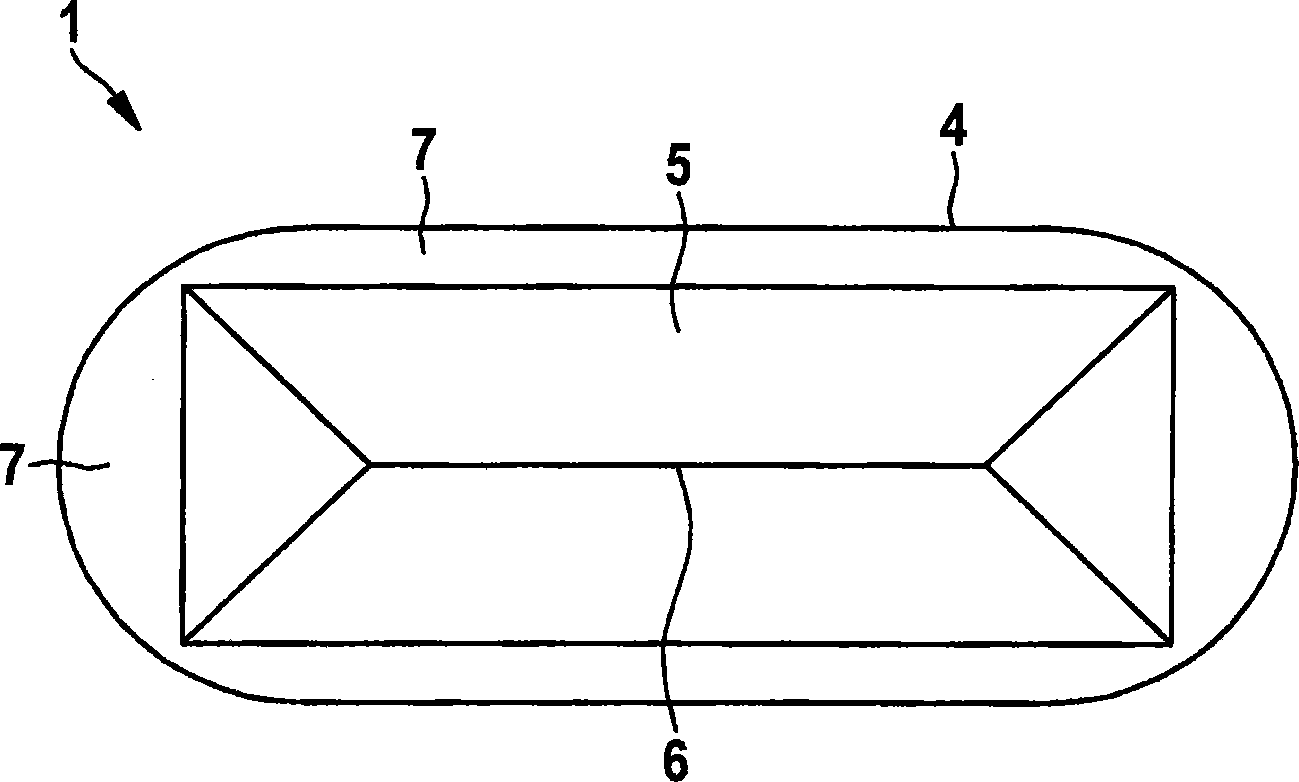

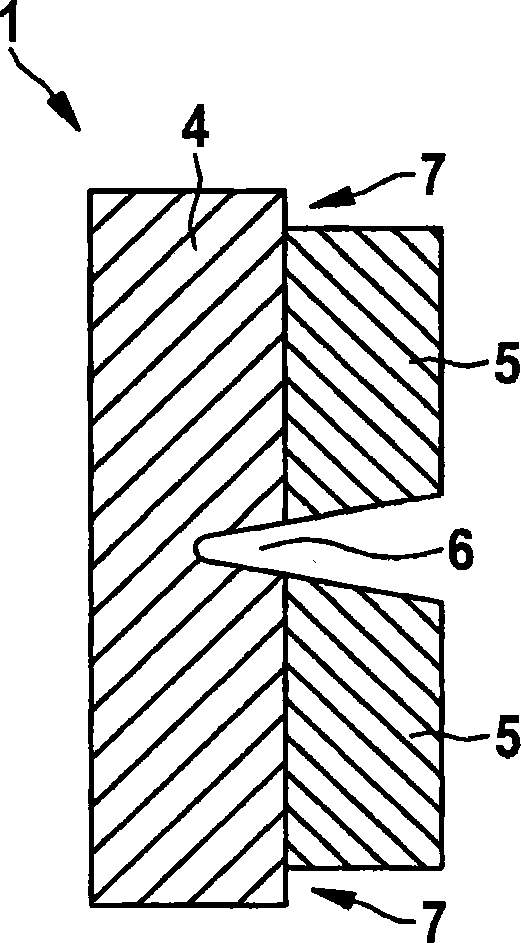

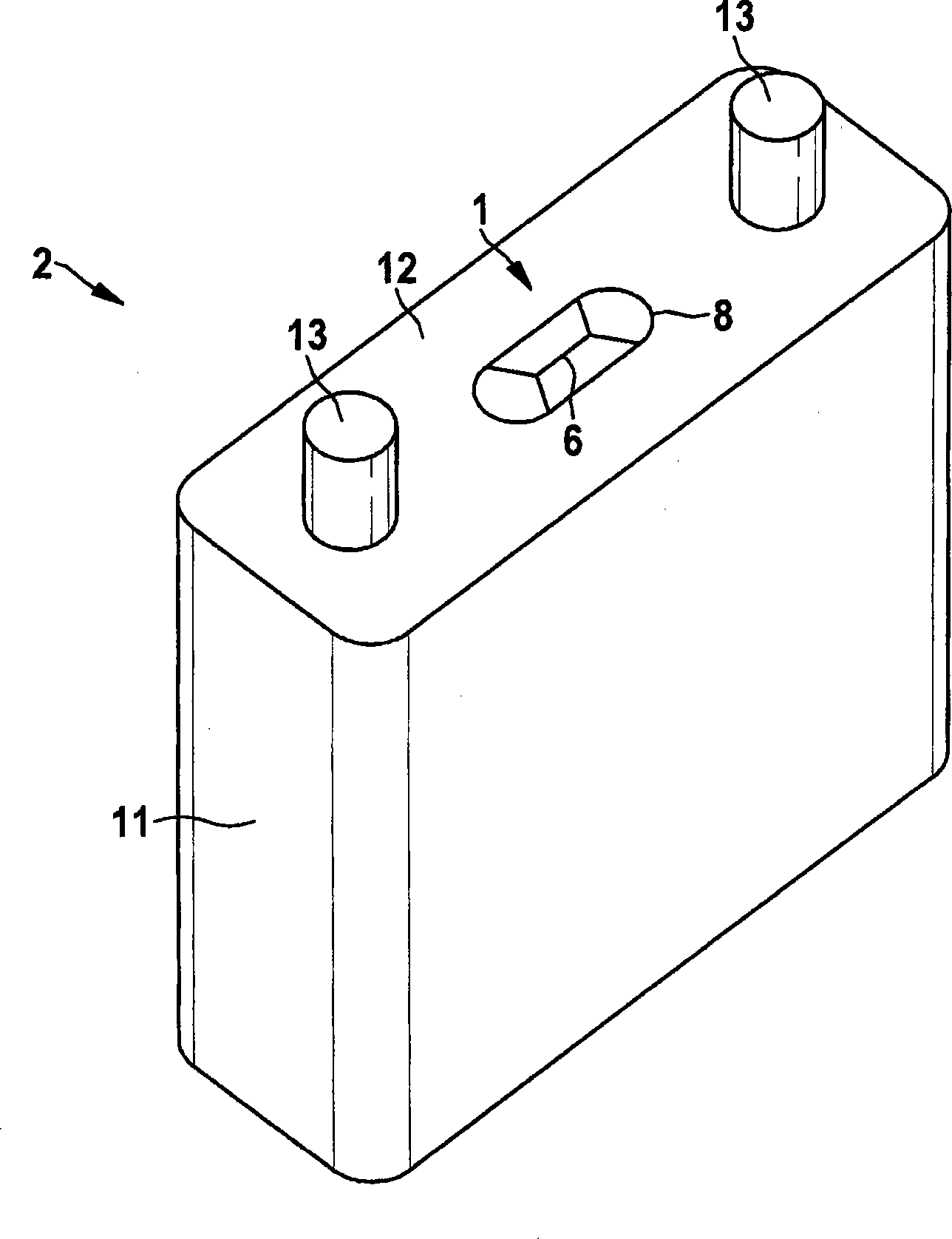

[0032] figure 1 An embodiment for a rupture element 1 configured as a rupture membrane is depicted in . The rupture element 1 comprises a substantially planar base body which is constructed in multiple layers. In this case, the rupture element 1 has a first layer 4 of a first metal and a second layer 5 of a second metal, wherein the first metal has a coefficient of linear expansion that is at least 5% greater than the second metal. The first layer 4 of the rupture element 1 can consist of aluminum, for example, and the second layer 5 of the rupture element 1 can consist of zinc. The first layer 4 and the second layer 5 of the rupture element 1 are connected to each other by a firm joint, preferably by means of cold welding.

[0033] figure 1 The rupture element 1 depicted in has a rupture point 6 . This breaking point is preferably embossed after the firmly bonded connection of the first layer 4 and the second layer 5 . The rupture behavior of the rupture element 1 is adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com