Compressed air brake device and leak detection method for rail vehicles

A technology of compressed air and braking devices, which is applied in the layout of pipelines, railway vehicle testing, brakes, etc., which can solve the difficulties of increasing the identification of brake pressure loss, unreliable identification of brake pressure loss, and leakage cannot be identified, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

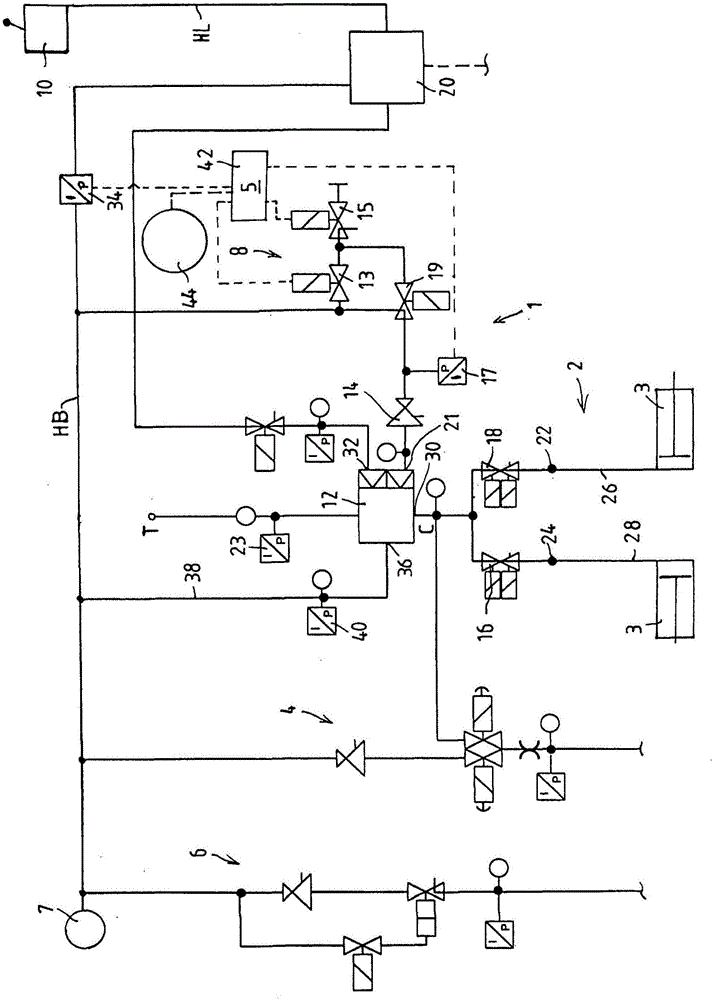

[0036] exist figure 1shows a schematic circuit diagram of part of a preferred embodiment of an electro-pneumatic compressed air braking system 1 for a rail vehicle or a train consisting of a plurality of rail vehicles, the electro-pneumatic compressed air braking system comprising a direct-acting Electro-pneumatic microprocessor-controlled brakes ("direct brakes") and indirect acting brakes ("indirect brakes").

[0037] A single rail vehicle has, for example, two bogies, and the bogies 2 have, for example, two braked axles, which each have two pneumatically actuated brake cylinders 3 . exist figure 1 Only one brake cylinder 3 is depicted in each case. Each bogie 2 is controlled individually, for example by means of a compact control module CCM not explicitly shown here, so that for each bogie 2 a separate brake pressure C can be formed for, for example, four brake cylinders. For this purpose, an electronic brake controller 5 is integrated in each compact control module CCM....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com