Electric switch cabinet set body

A technology for electrical switches and cabinets, applied in substation/switch layout details, electrical components, substation/distribution device shells, etc., can solve the problems of complex production process, poor mechanical strength and low production efficiency of switch cabinet cabinets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

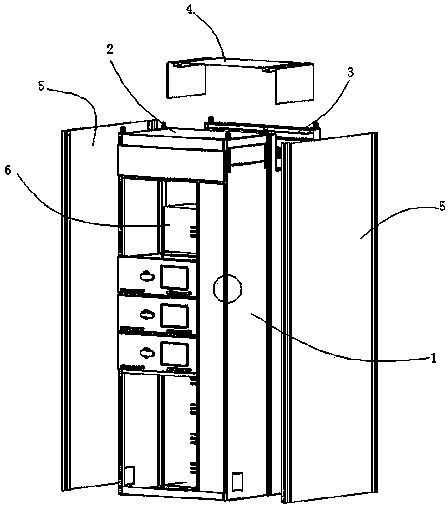

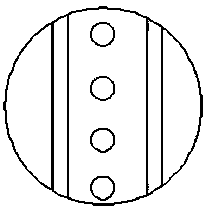

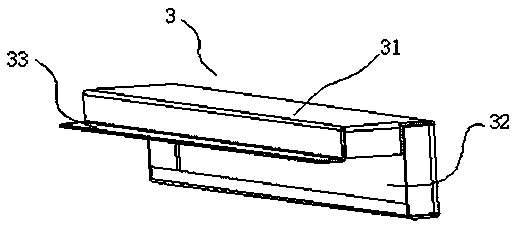

[0028] Such as figure 1 , as shown, the cabinet frame 1 is a cuboid frame, only the left and right sides and the bottom surface of the cabinet frame 1 are provided with panels, and the top of the cabinet frame 1 is provided with a front cover 2 that only covers part of the cabinet frame top, The cabinet frame 1 is composed of a plurality of rectangular parallelepiped profiles, and the inside and outside of the column of the cabinet frame 1, the underside of the top beam and the upper side of the bottom beam are stamped with a plurality of evenly spaced mounting holes (such as figure 2 As shown), the two sides of the rear panel and the sides of the cabinet door are punched with the same uniformly spaced installation holes as those on the cabinet frame 1.

[0029] The cabinet adopts the profile assembly process to make a fully enclosed cabinet, which is formed by bending and assembling the plates. After the plate is bent, it has the advantages of section steel. There are no le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com