An automatic assembly equipment for tg side panel components

An automatic assembly and side plate technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of complex and time-consuming assembly process, and achieve high assembly efficiency, high assembly precision, and high product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

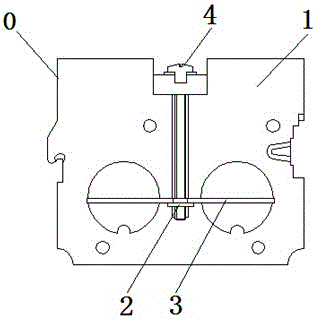

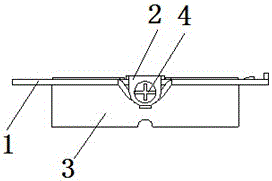

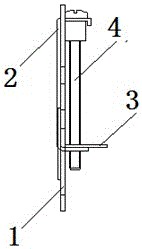

[0041] Such as Figure 4As shown, an automatic assembly equipment for TG side plate assembly includes a rotary table, and eight assembly clips 100 are evenly distributed in a ring on the turntable 5 of the rotary table, with the rotary table as the center, and the large table around it The plate 6 is sequentially provided with a side plate loading mechanism 200 that sends the side plate 1 to a predetermined position on the assembly clip 100, a hook loading mechanism 300 that sends the hook 2 to a predetermined position on the assembly clip 100 and snaps on the side plate 1, The adjustment piece 3 is sent to the predetermined position on the assembly clip 100 and placed on the adjustment piece loading mechanism 400 at the lower end of the hook 2, and the screw 4 is sent to the predetermined position on the assembly clip 100 and locked into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com