Eight-station automatic assembly equipment

An automatic assembly, eight-station technology, used in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problem of automatic assembly and processing equipment is still blank, etc., to achieve a small footprint, high assembly accuracy, assembly Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

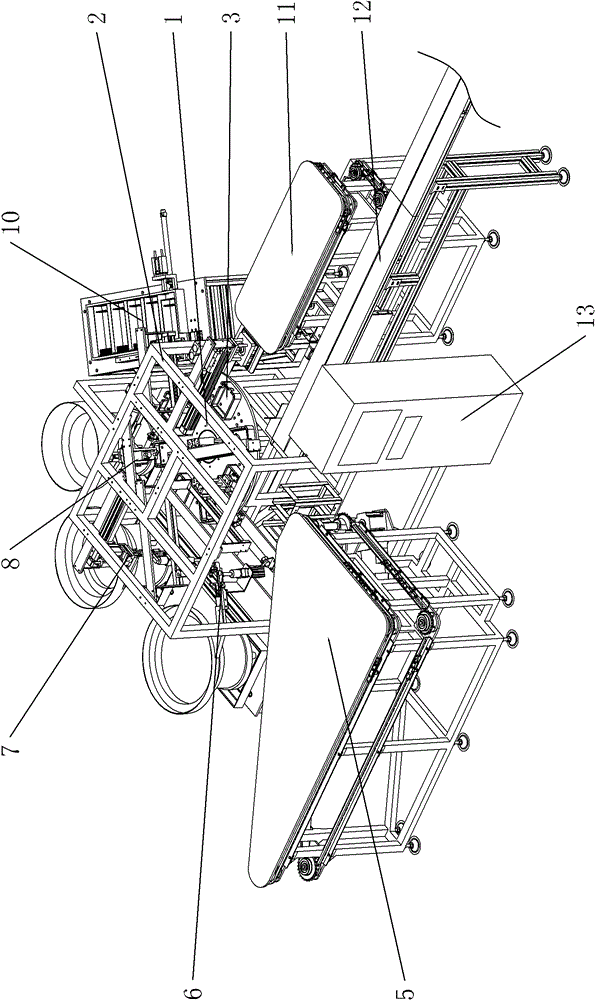

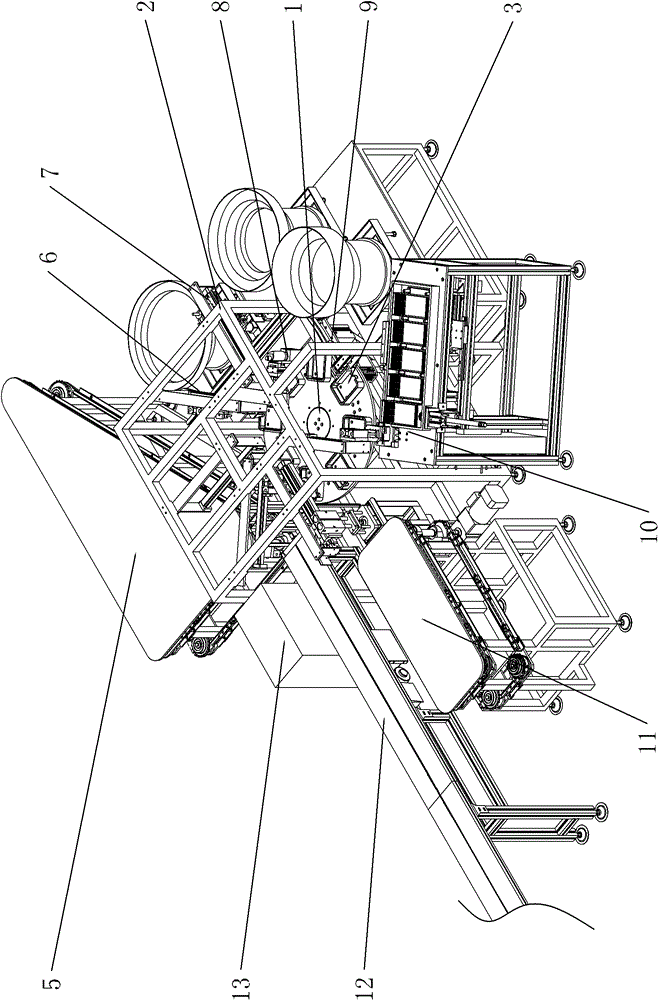

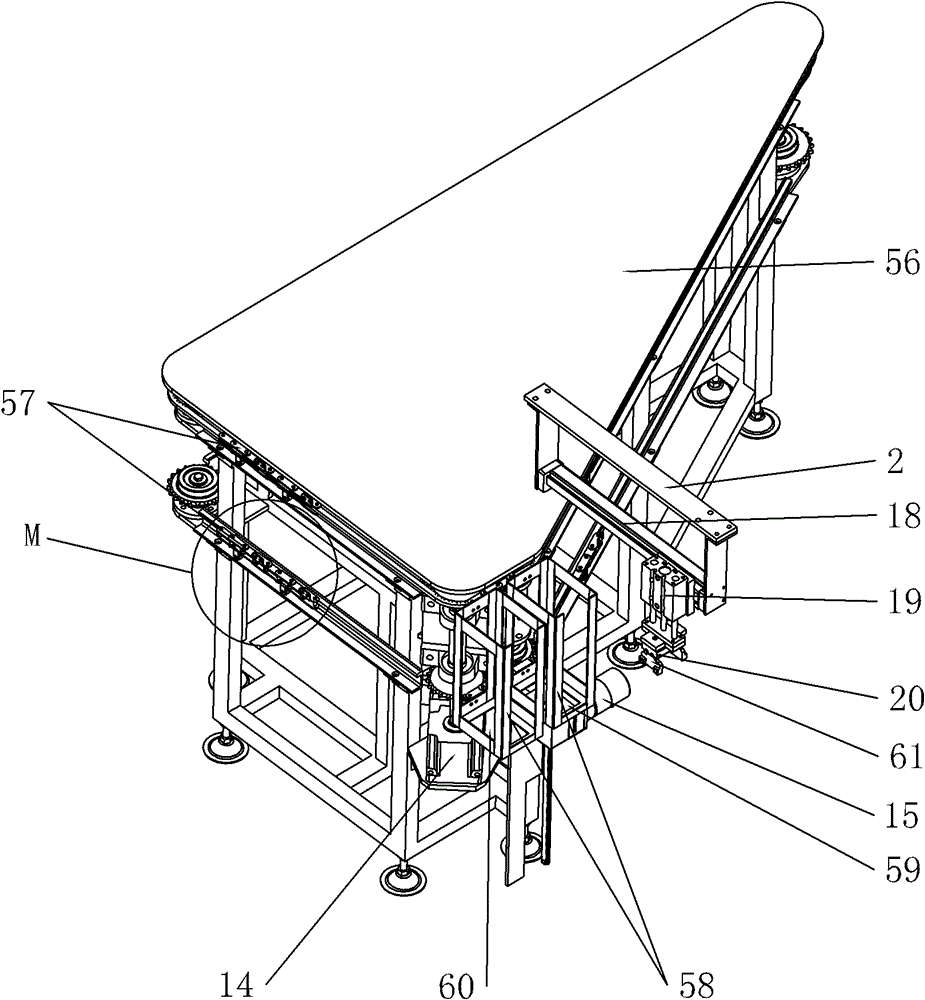

[0037] Implementation Mode 1: For details, see figure 1 and 2 As shown, the present invention is a kind of eight-station automatic assembly equipment, wherein, the rotary table 1 is arranged in the outer support 2, and eight box molds 3 are evenly distributed on the rotary table 1, and the box mold 3 has a longitudinal side and There is a "U"-shaped groove 4 on one lateral side, with the rotary table 1 as the center, and a box loading device 5 for lifting the box and placing it in the box mold 3 is arranged around it, and the regulating valve is inserted into the box. The regulating valve loading device 6, the screw loading device 7 that connects the regulating valve to the box body, the screw tightening device 8 that tightens the screw, and the transition joint loading device that inserts the transition joint into the regulating valve and snaps into the box body Device 9, a stencil loading device 10 for inserting the stencil into the box body, a box cover loading device 11 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com