A watch negative guide mechanism

A technology for guiding mechanism and clock movement, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of increased production cost, low assembly efficiency, easy to be cut and so on of the negative electrode of manual assembly movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

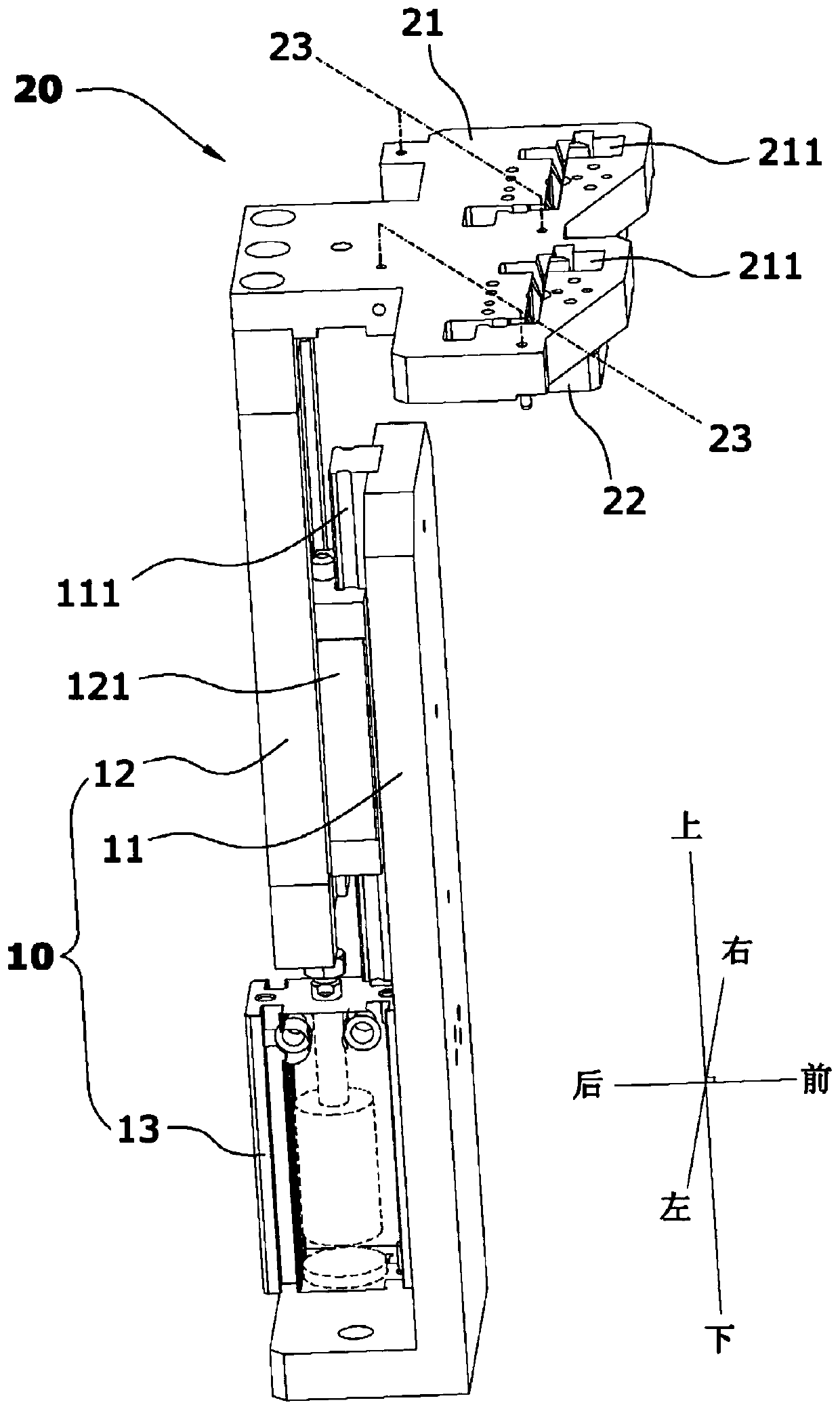

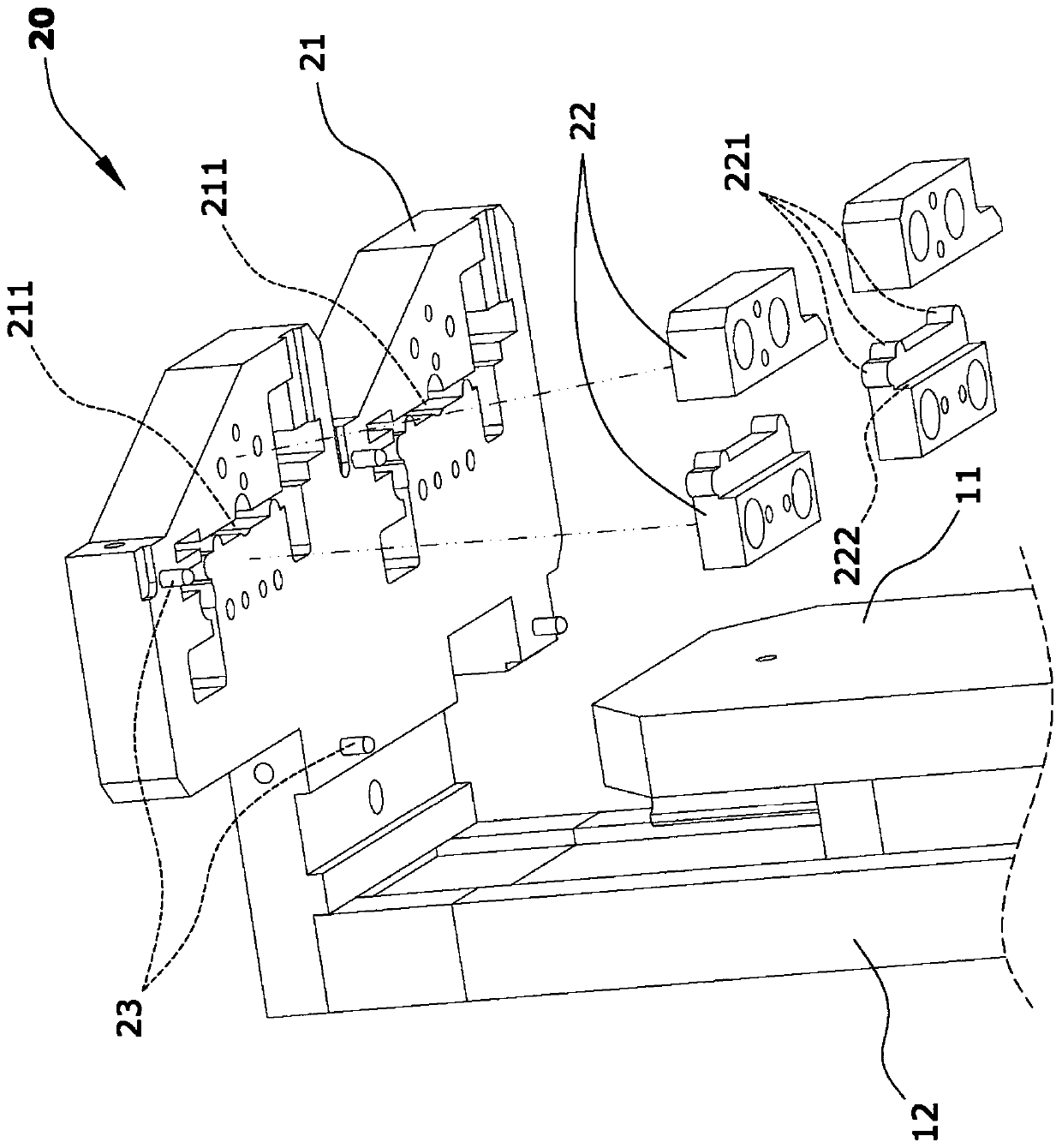

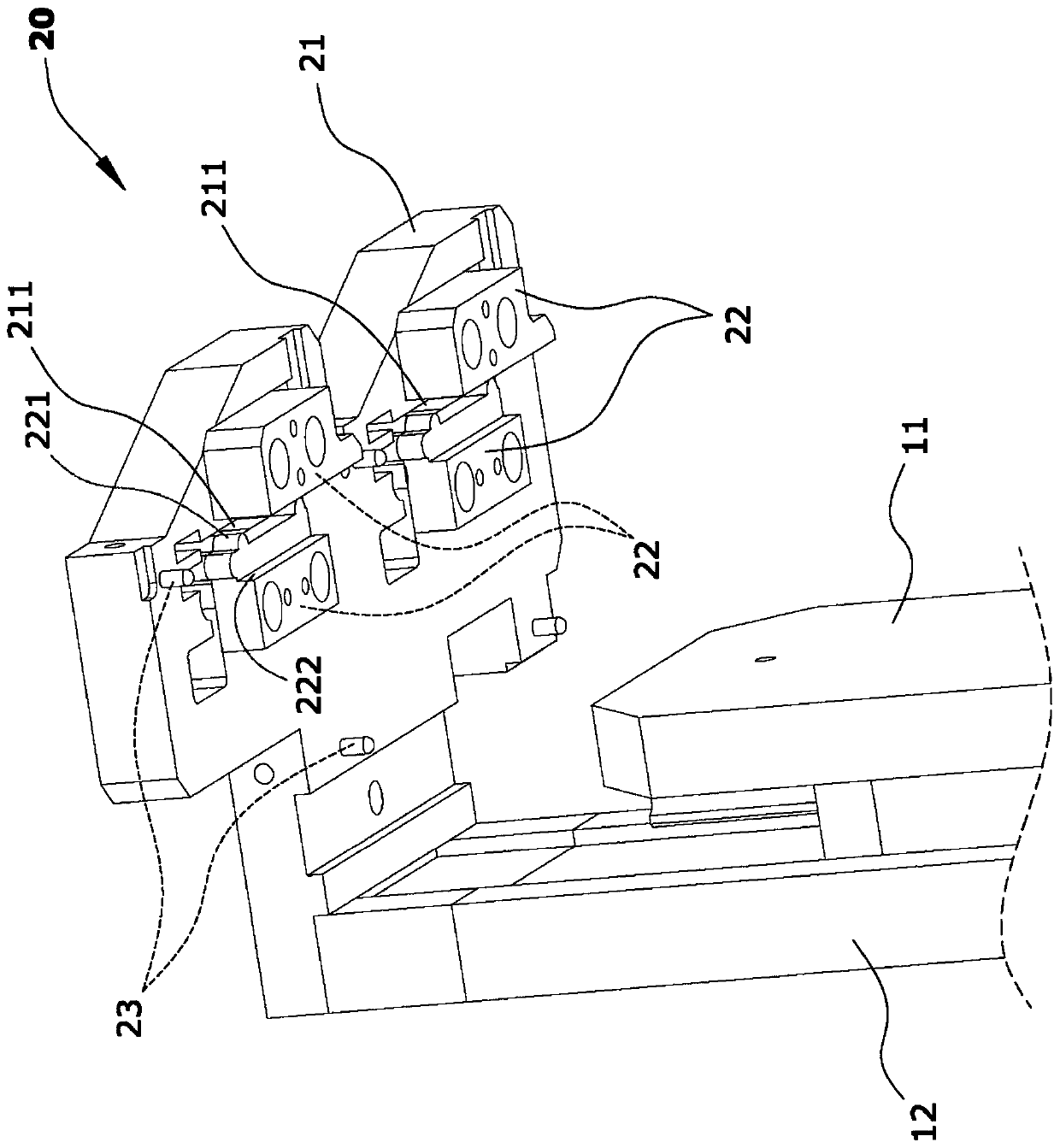

[0022] Such as figure 1 and Figure 6 A watch negative guide mechanism shown, which is installed on the automatic assembly line of watch movement, includes a guide block 20 for guiding the negative electrode sheet K to enter the cavity of the movement M and a guide block for vertical lifting and lowering. The lifter 10 of the block 20, the guide block 20 includes a position guide plate 21, and a guide groove 211 for the negative electrode sheet K to pass vertically downward in the posture of installation is respectively provided on the position guide plate 21, each guide groove 211 can vertically align the position of the negative electrode sheet in the two core M-shaped cavities under the guide block 20 .

[0023] Such as Figure 1 ~ Figure 4 , Figure 6 and Figure 7 As shown, the elevator 10 of the present invention includes a vertical plate 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com