A high-strength and low-noise diamond circular saw blade substrate

A diamond and high-strength technology, applied in the field of cutting tools, can solve problems such as stress concentration at the tooth root, fatigue cracks, and unstable cutting process, so as to reduce the cutting impact, optimize the force of the sawtooth, and avoid discontinuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

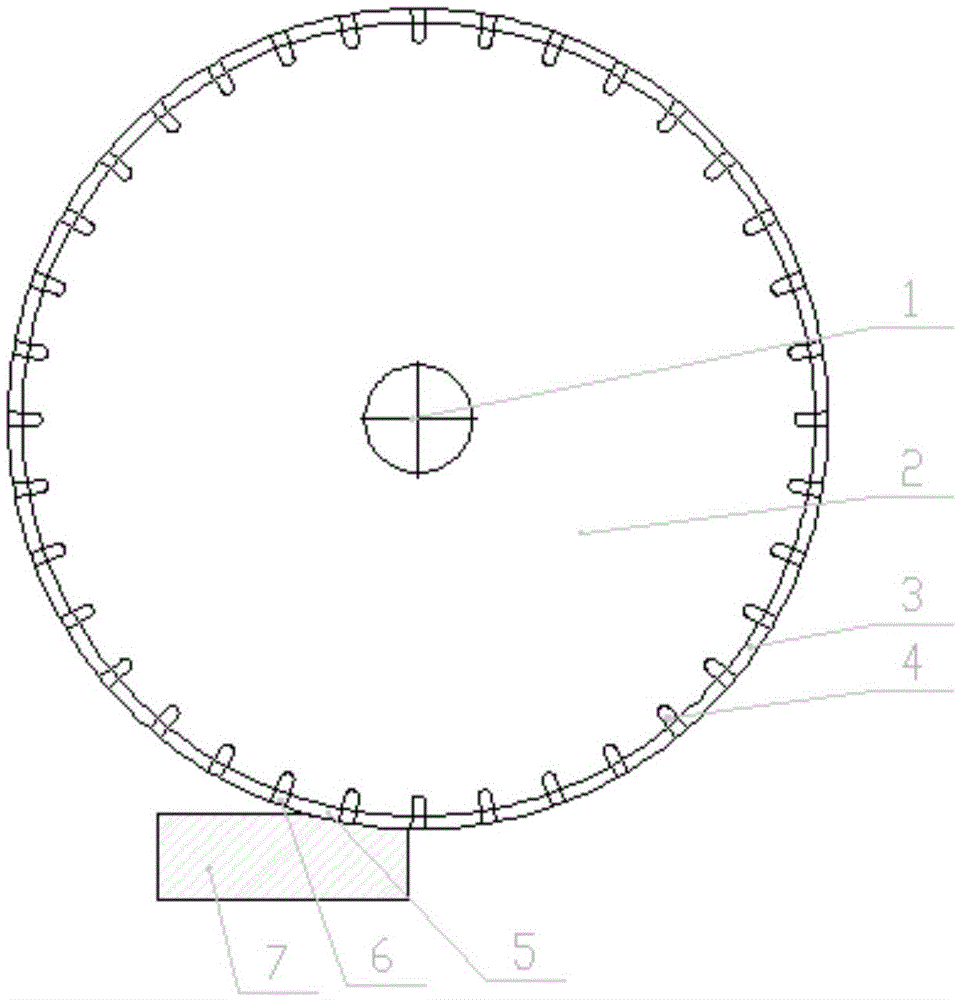

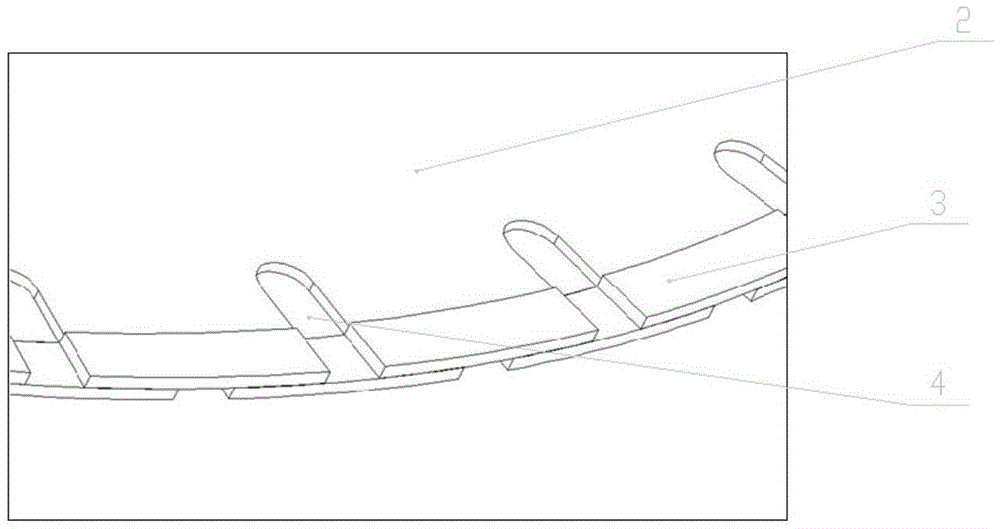

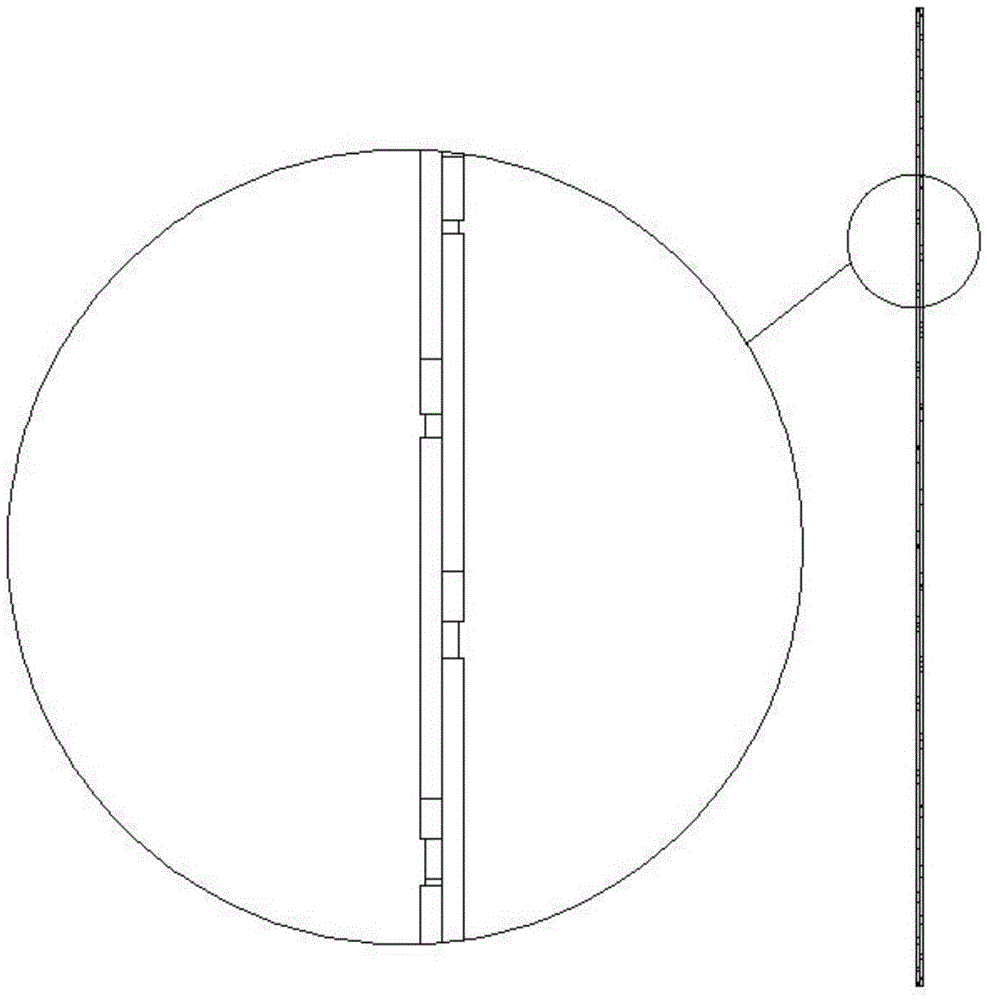

[0020] Such as figure 1 , figure 2 As shown, the present invention includes a saw blade base body 2, a central hole 1 is provided on the saw blade base body 2, a central hole 1 is provided at the central position of the saw blade base body 2, and outside the two radial surfaces above and below the saw blade base body 2 There are semi-penetrating water grooves 4 evenly distributed on the circle, and the depth of the half-penetrating water grooves 4 is half of the thickness of the saw blade substrate 2; the interval distribution here refers to; There is a semi-penetrating water tank on the lower radial plane between each two half-penetrating water tanks on the lower radial plane; there is a semi-penetrating water tank on the upper radial plane between every two The serrations formed between the adjacent semi-penetrating water tanks 4 are provided with cutter heads 5, and all the cutter heads 5 form a circle; that is, a circle of cutter heads is provided on the upper radial su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap