Vertical lifting type disc-shaped aircraft

A vertical lift and aircraft technology, applied in the field of aircraft, can solve the problems of high material strength requirements, cumbersome manufacturing process, and high manufacturing costs, and achieve the effects of low material strength requirements, improved flight efficiency, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

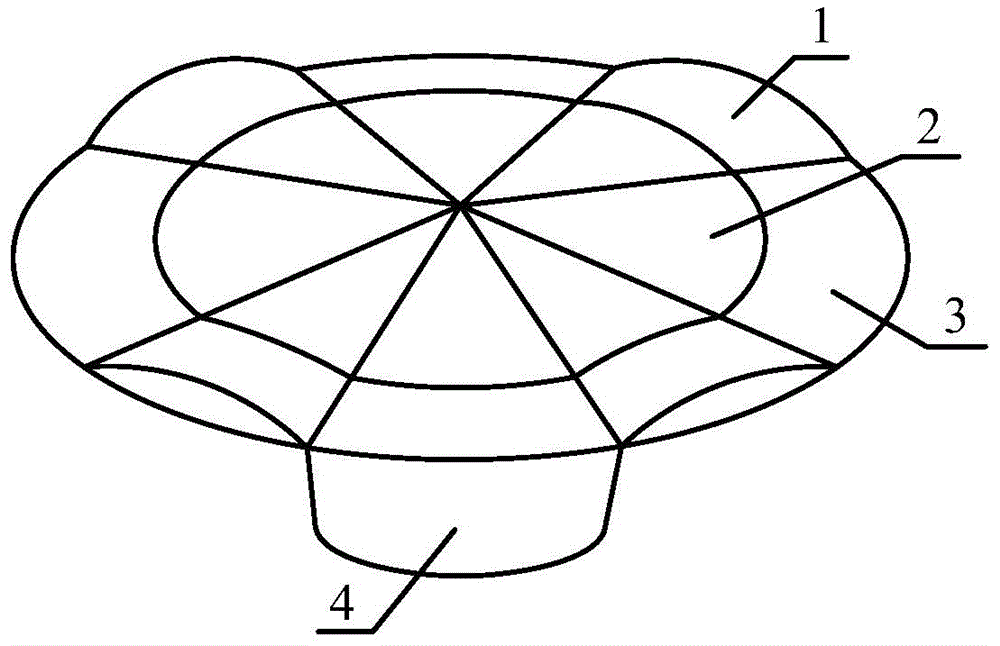

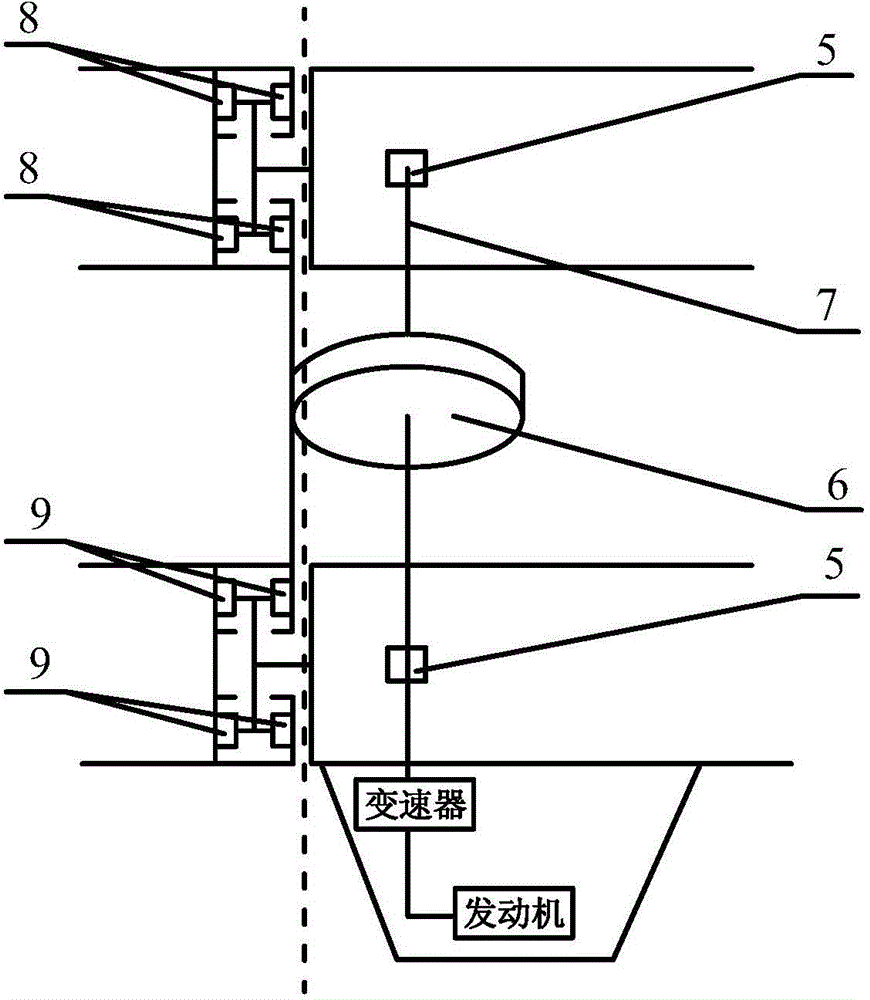

[0024] see figure 1 As shown, the embodiment of the present invention provides a vertical lift type disc-shaped aircraft, including a disc and a control cabin 4 connected to the disc. The disc includes an inner disc 2 and at least one outer disc 3. In practical applications, The disc can include one inner disc 2 and one outer disc 3 , or one inner disc 2 and two outer discs 3 , or one inner disc 2 and three outer discs 3 . The inner disc 2 has a disc-shaped structure, the outer disc 3 has a ring-shaped structure, the inner disc 2 and the outer disc 3 are coaxial, and the upper surface of the disc is provided with at least two upwardly raised ridges 1 radiating from the center of the disc, for example: two , 3 or 4 ridges 1 . The cross section of the ridge 1 is fan-shaped, the center of the circle where the fan is located coincides with the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com