Splay-track flapping wing mechanism and miniature flapping wing air vehicle

A trajectory and horoscope technology, applied in the field of flapping wing mechanism, can solve the problems of low efficiency of flapping wing movement, small flexibility of flapping wing mechanism, inability to generate lift at the same time, and achieve the effect of fast speed and high flight efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

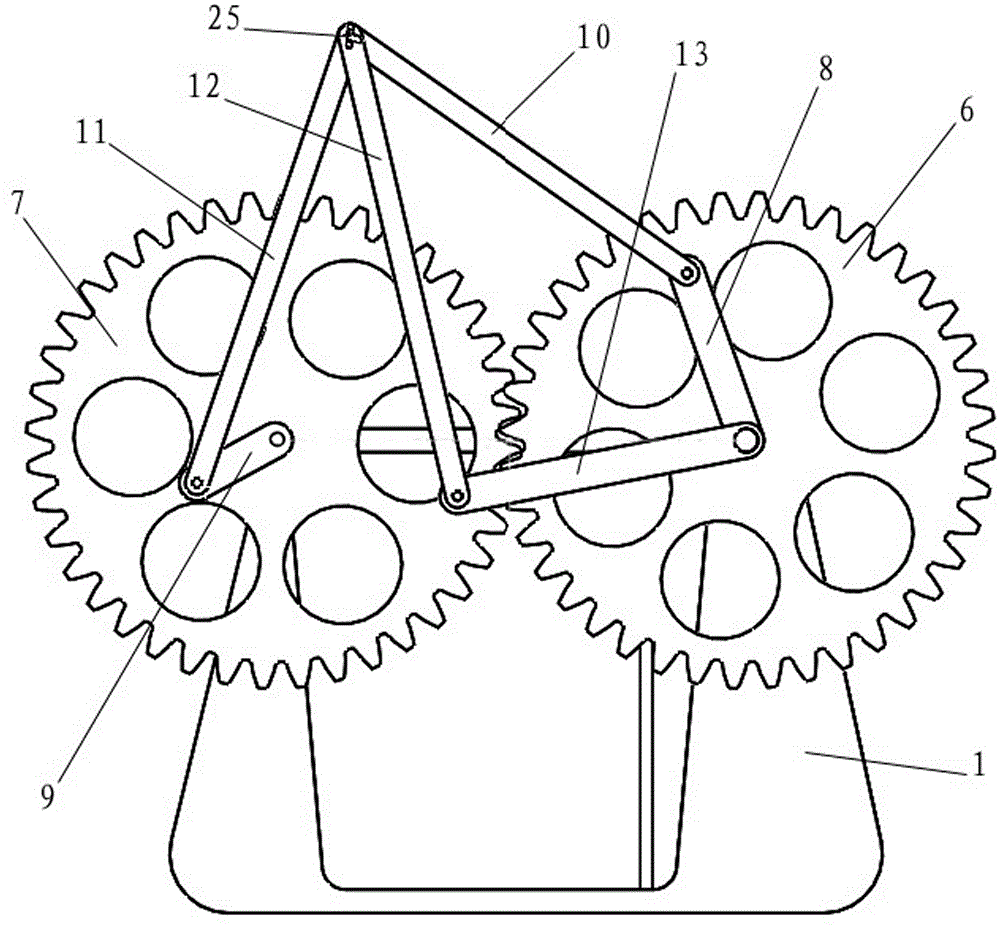

[0020] In the present invention, the research focus is mainly on the realization of the bionic flapping wing mechanism. The figure-eight trajectory motion mechanism is one of the bionic flapping wing mechanisms, based on hummingbirds, and its hovering characteristics can provide more flexibility for micro-aircraft. In addition, the study found that the figure-of-eight flapping trajectory combined with specific wing surface reversal movements can simultaneously generate lift and thrust in one flapping cycle, which is more efficient than traditional flapping movements.

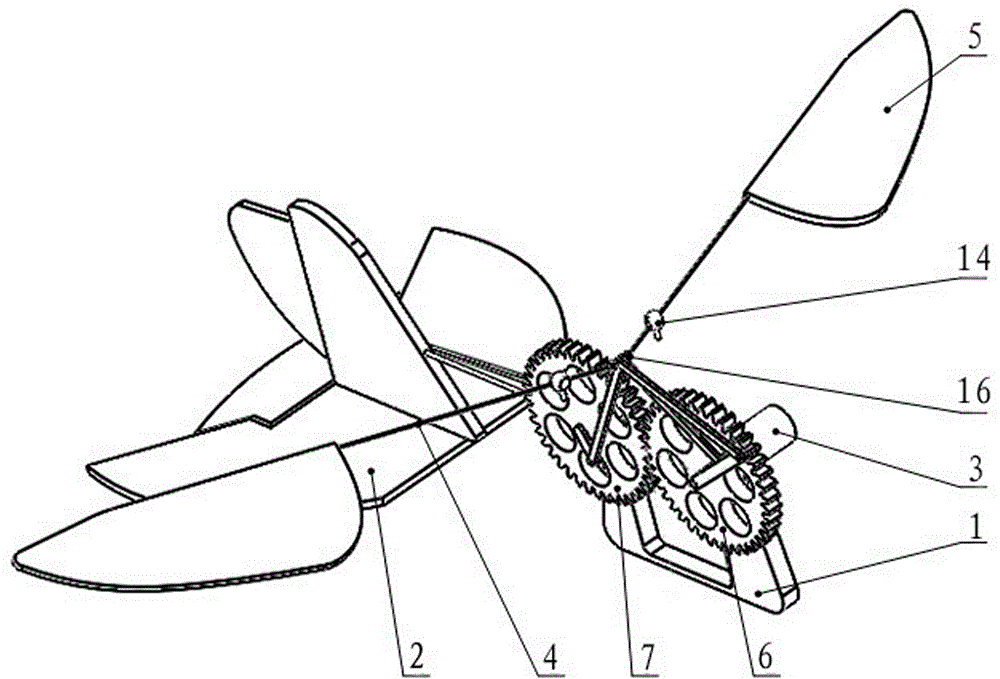

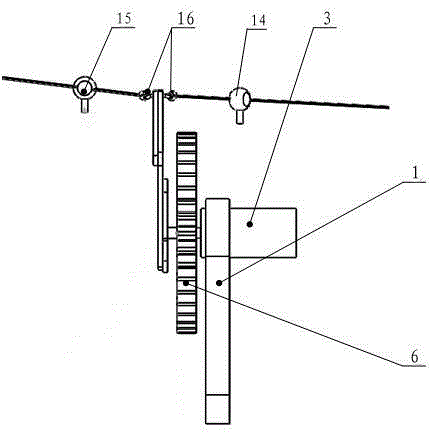

[0021] Specific as figure 1 As shown, the figure-of-eight trajectory flapping wing mechanism that the present invention proposes comprises: frame 1, the wing that is located at the top of frame 1, the empennage 2 that is located at the rear of frame 1 and the driving motor 3 that is fixed on the frame, machine Wing is made of two rocking bars 4 that are symmetrically arranged and two flapping wings 5 that are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com