Control room for hoisting equipment

A lifting equipment and control room technology, applied in the field of lifting equipment, can solve the problems of easy occurrence of unsafe, inconvenient observation of the situation above and below the lifting goods, and achieve the effect of increasing the scope of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

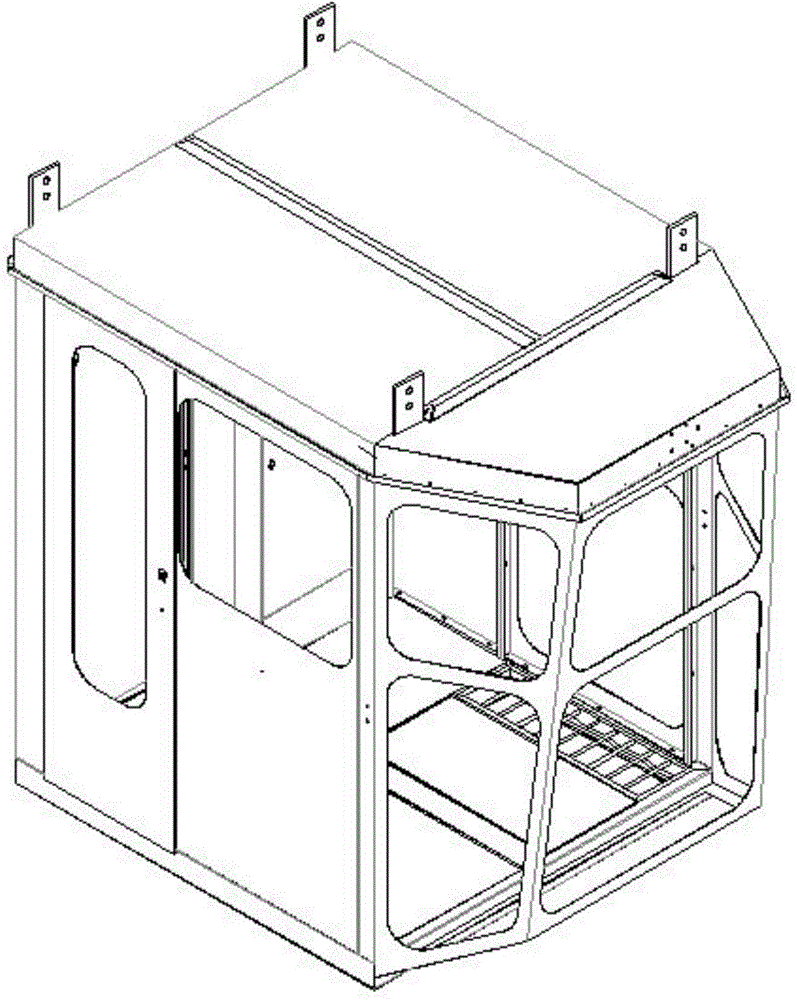

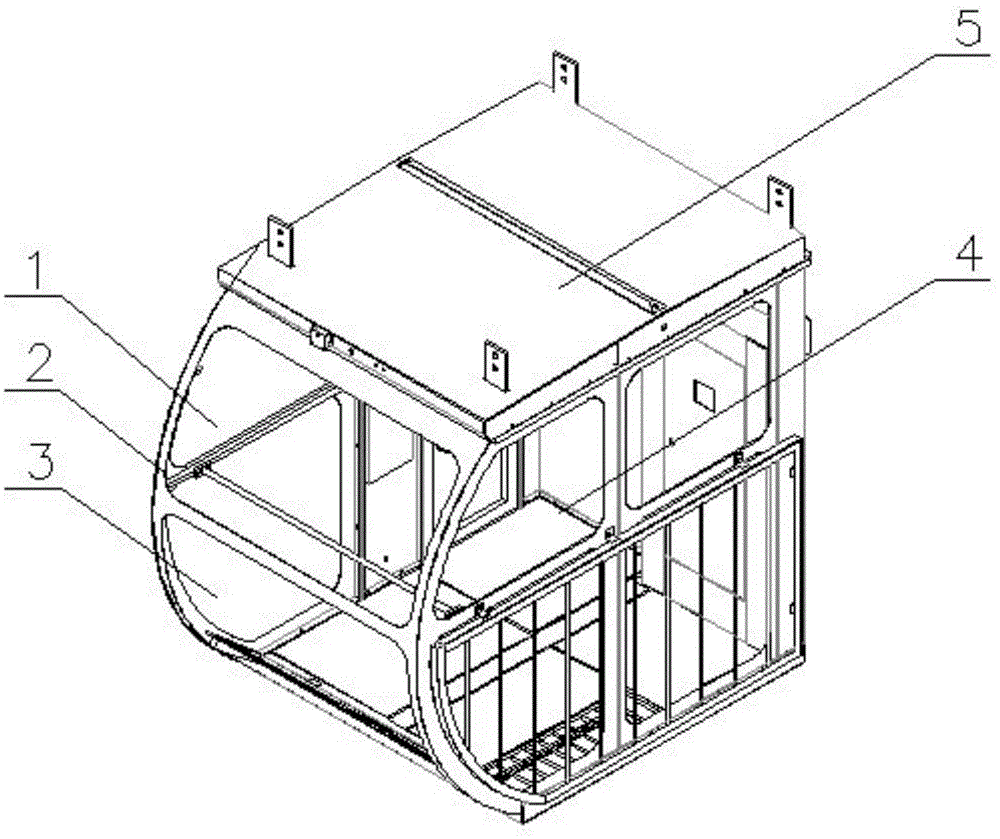

[0011] Lifting equipment control room, including the control room frame; the top, bottom, and back of the control room frame are all equipped with metal plates; the curved surface where the front frame of the control room frame is located is an arc-shaped surface, and the center of the arc-shaped surface is Inside the control room, the front frame of the control room frame is provided with arc-shaped curved glass; the side of the control room frame is provided with sliding glass windows.

[0012] Among them, the front frame of the control room frame is provided with two arc-shaped curved glass.

[0013] The biggest innovation of the present invention is that, according to the convex lens principle, the front of the control room adopts arc-shaped curved glass, which greatly increases the field of vision of the operator.

[0014] The present invention designs a brand-new lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com