Turnover headrest with double locking positions

A headrest and locking technology, which is applied to the special position of the vehicle, vehicle parts, vehicle seats, etc., can solve the problems of poor convenience and ease of use, and achieve the effects of high feasibility, increased convenience, and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

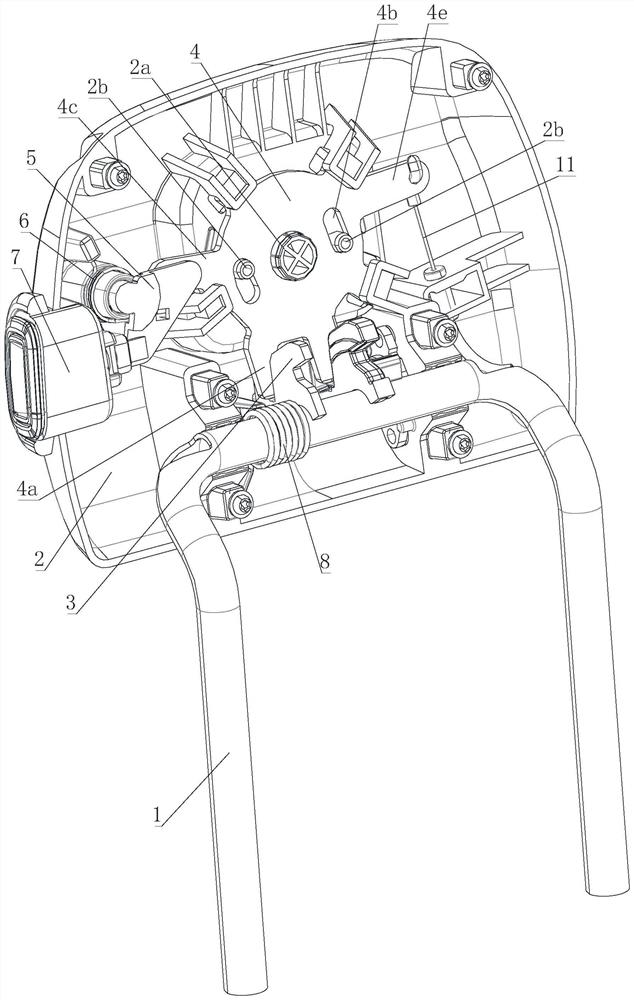

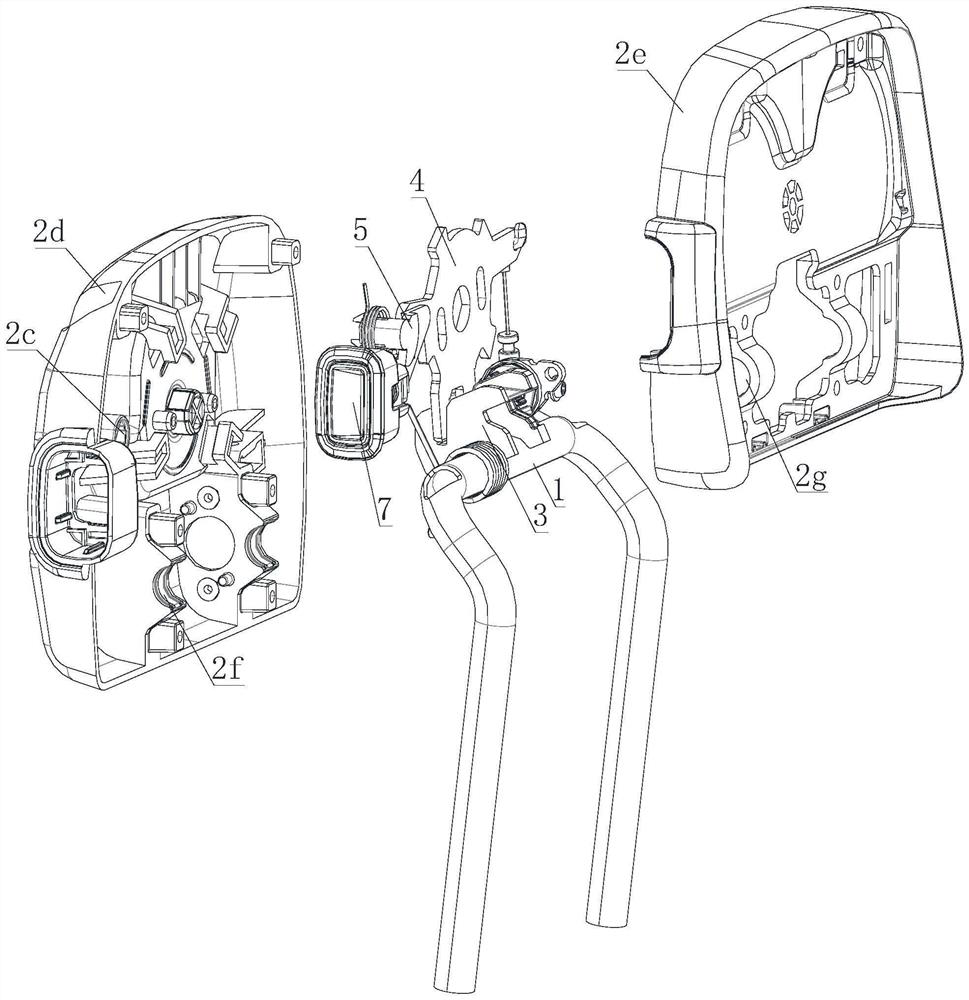

[0033] Such as figure 1 with 2 As shown, a folded headrest includes a headrest rod 1 and a headrest base 2. The headrest base 2 is composed of a front shell 2d and a rear shell 2e assembled and connected together. The lower part of the front shell 2d is provided with a second A half-ring groove 2f, a second half-ring groove 2g is provided on the lower part of the rear housing 2e, and the headrest base 2 is connected to the headrest through a circular hole surrounded by the first half-ring groove 2f and the second half-ring groove 2g. on pole 1.

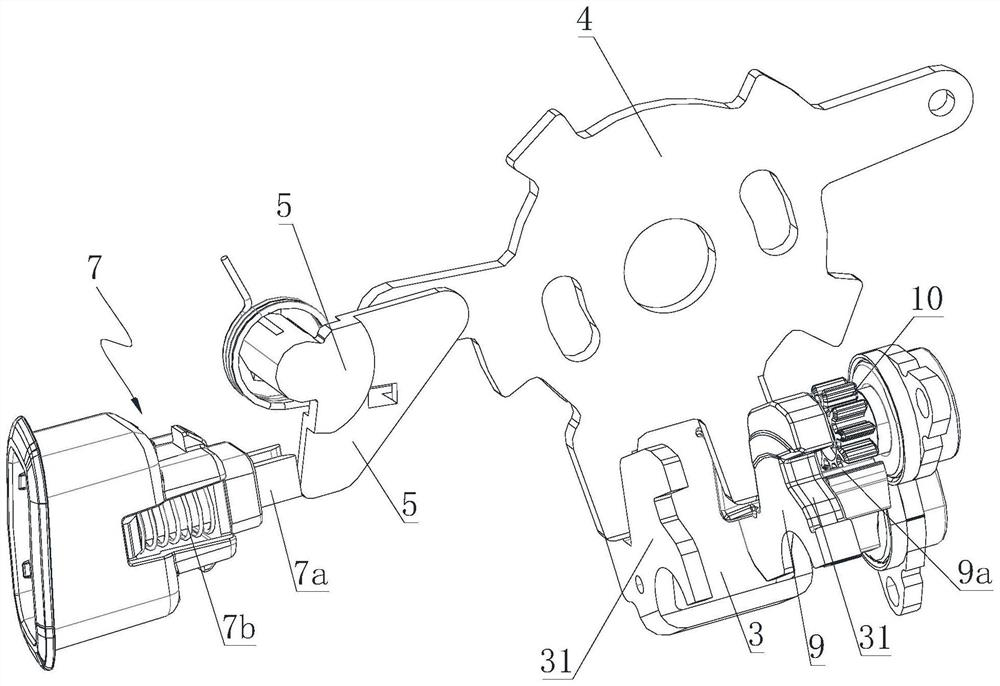

[0034] Another example figure 1 with 3 As shown, the limit part 3 is fixedly installed on the headrest rod 1, and the limit part 3 is provided with a use limit groove 3a and a folding limit groove 3b. distribution of rotation directions. A lock disc 4 and a linkage part 5 are installed in the headrest base 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com