Roof structure for railway passenger cars

A technology for railway passenger cars and live roofs, which is applied in the field of rail vehicle body structure, can solve the problems of increasing product development cycle and cost, waste of resources, etc., and achieves the effect of high production efficiency and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

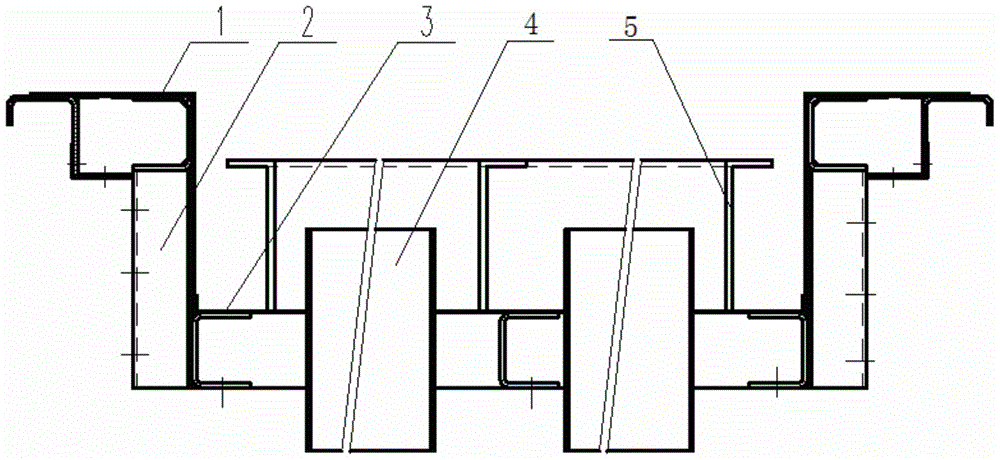

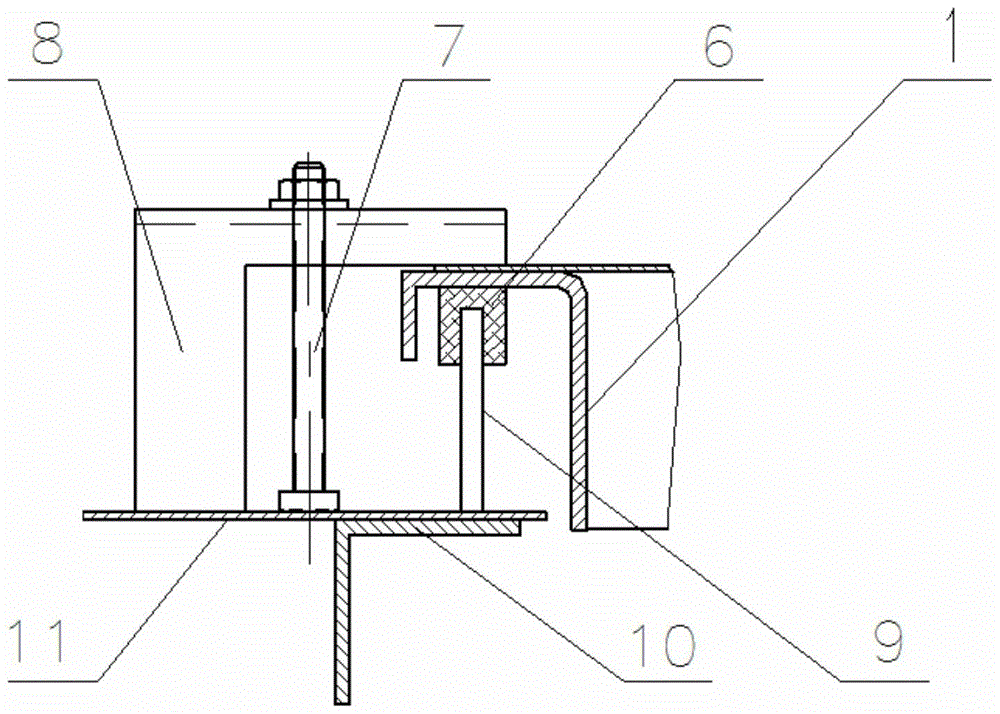

[0016] Such as figure 1 , figure 2 As shown, the movable roof structure of the railway passenger car in this embodiment includes a flat top part 3, an arc frame 2 fixed on the front and rear sides of the flat top part 3, a dome part 1 fixed with the arc frame 2, and a flat top part. 3. The arc frame 2 and the dome part 1 are all fixed on the welding frame. The flat top part 3 is fixed with the equipment mounting seat 5 and the air guide tube 4. The left and right sides of the flat top part 3 have side beams, and the side beams Welded lugs. A movable roof installation frame 9 is arranged laterally on the passenger car dome plate 11 and bolts 7 are fixed at intervals. The bolts 7 are fitted with weights 8, and a roof curved beam 10 located on the lower surface of the passenger car dome plate 11 is located below the movable roof installation frame 9. . The lower bottom surface of the dome part 1 is pressed on the movable roof installation frame 9 through the sealing rubber st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com