Flat knitting machine

A technology for knitting flat knitting machines and loom slides, which is used in knitting, weft knitting, flat knitting machines with separate action needles, etc. change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

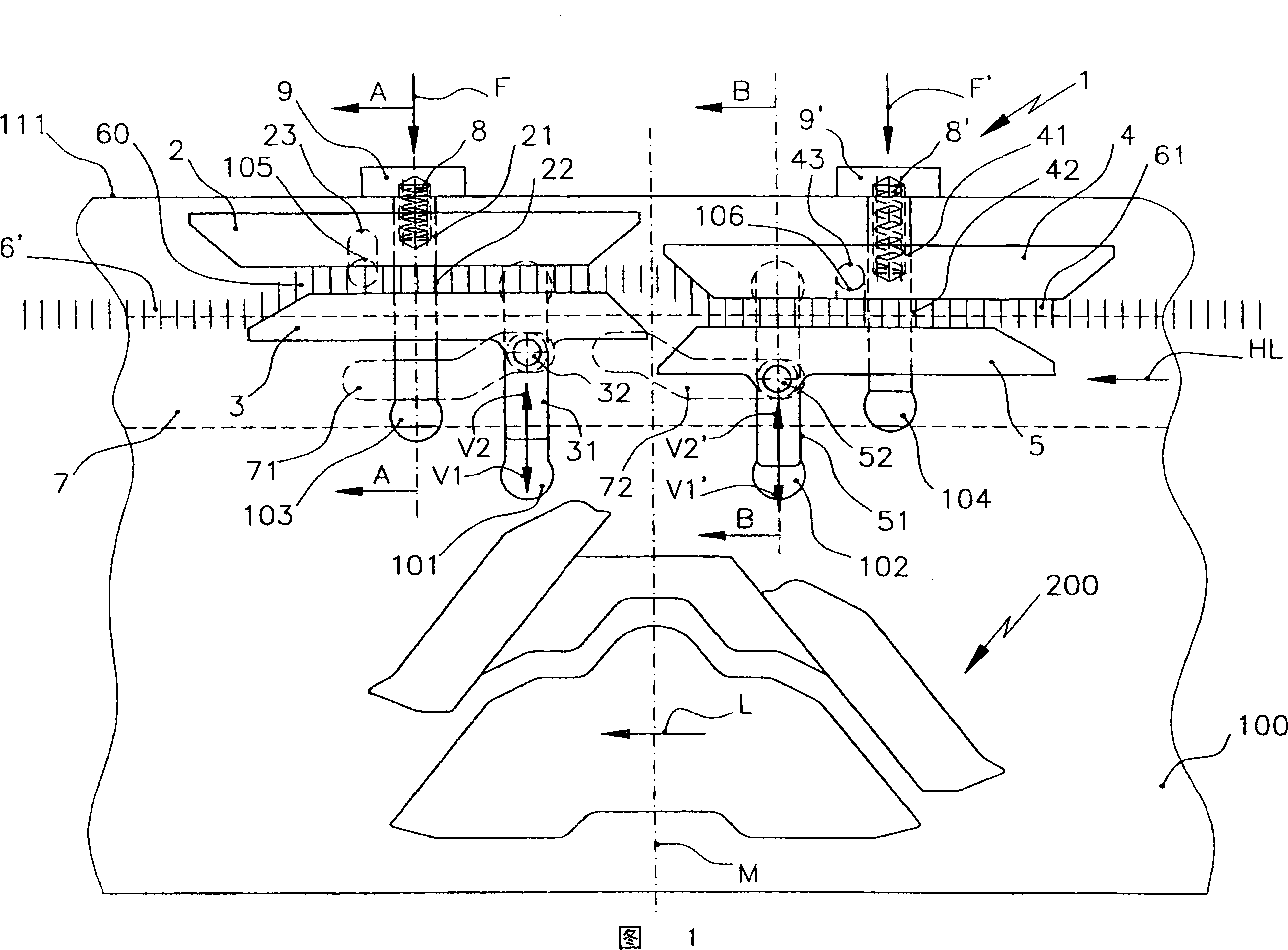

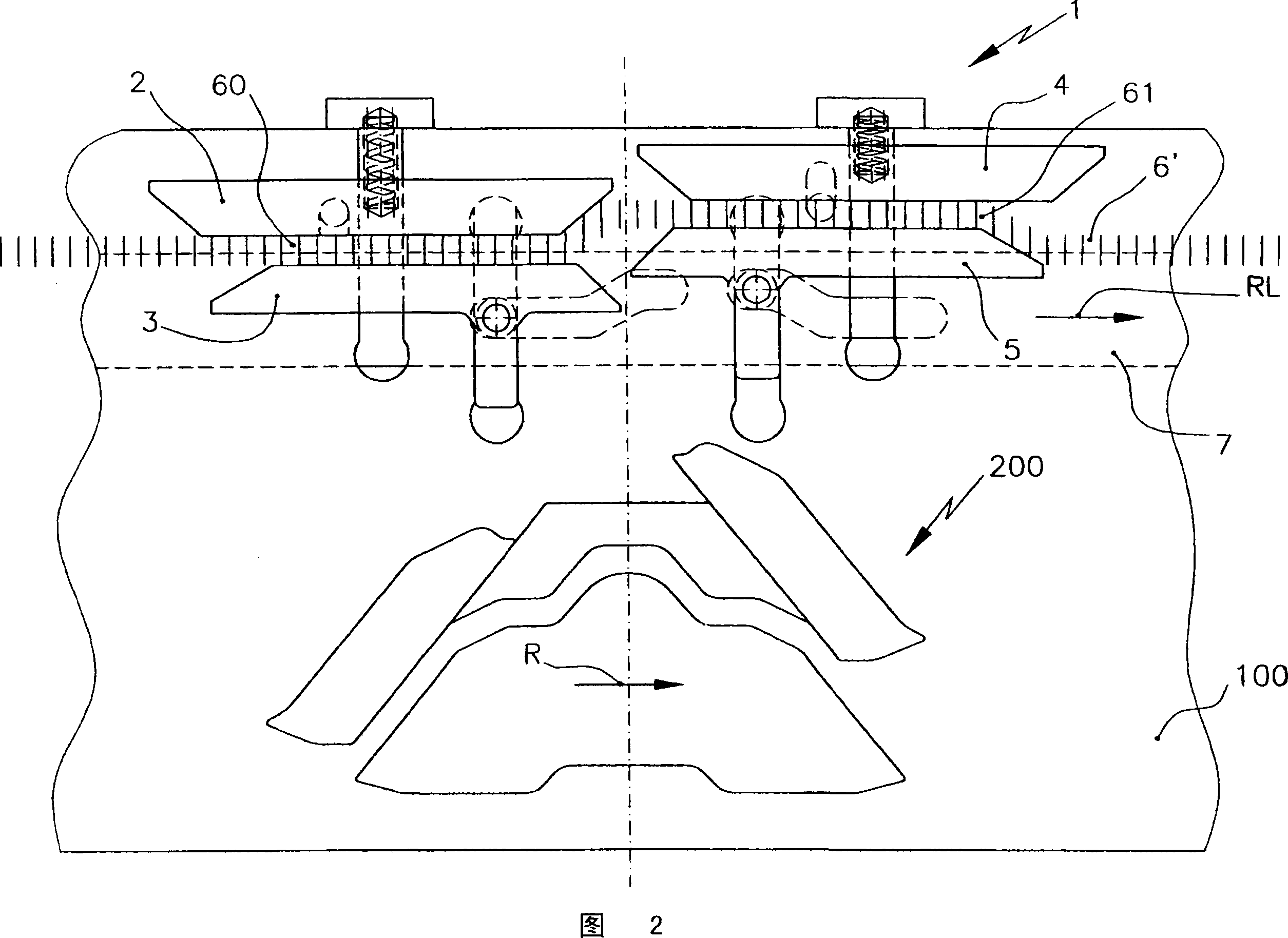

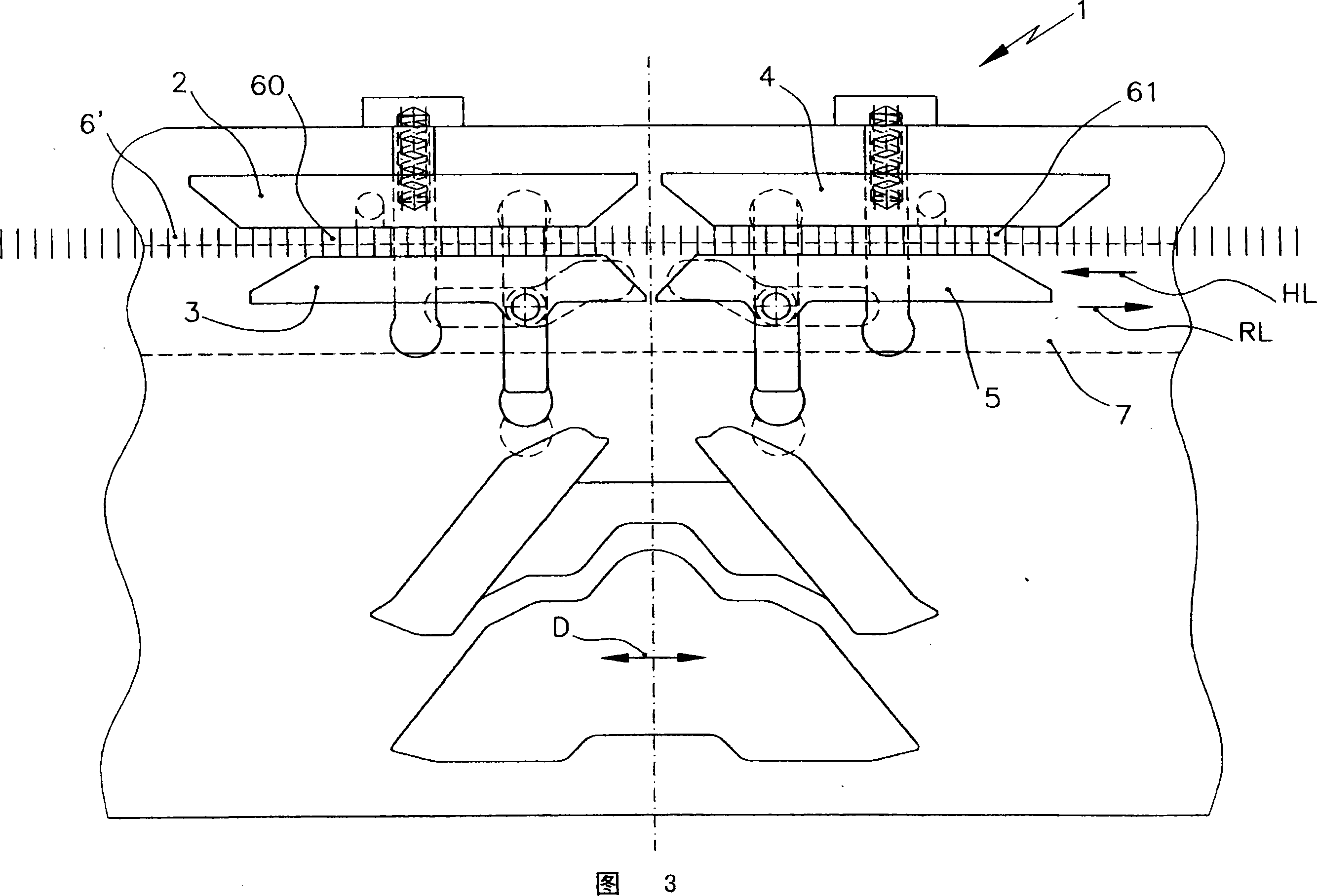

[0025] FIG. 1 shows a slider panel 1 , which is arranged on a panel base 100 above a triangular base 200 . The loom carriage, not shown, moves to the left in the direction of the arrow L in FIG. 1 , on which the panel base 100 with the panels 1 and 200 is fastened.

[0026] The slider panel 1 has a total of four panel parts 2 , 3 , 4 and 5 . In the example shown, the paneling parts 2 and 3 are arranged ahead of the central axis M of the triangular base 200 , while the paneling parts 4 and 5 are arranged behind. The panel parts 2 and 3 form the control track 60 of the control butt 6' of the slider 6 seen in detail in FIGS. 5 and 6 . Slider 6 is rotated by control rail 60 into comb slot 300 , which is likewise seen in FIGS. 5 and 6 . The panel parts 4 and 5 lagging behind the cam 200 form the control track 61 of the control butt 6 ′ of the slider, which is offset downwards compared to the control track 60 , so that the slider is again diverted from the comb gap 300 come ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com