Drill jumbo cab

A rock drilling rig and cab technology, applied in the field of construction machinery, can solve the problems of low cab height, operation errors, and inability to clearly see the movement of the boom, so as to increase the height of the field of view and prevent operation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

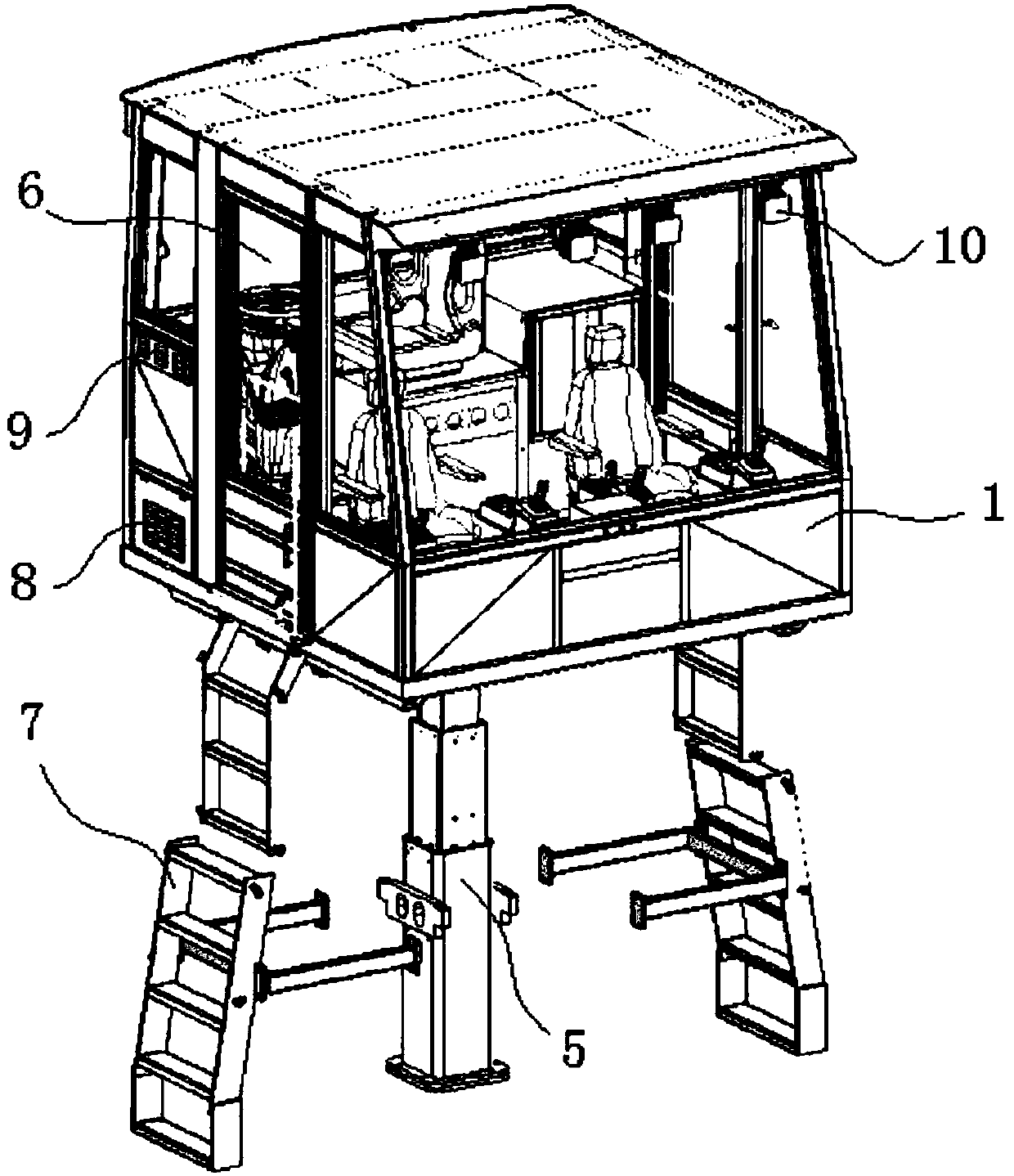

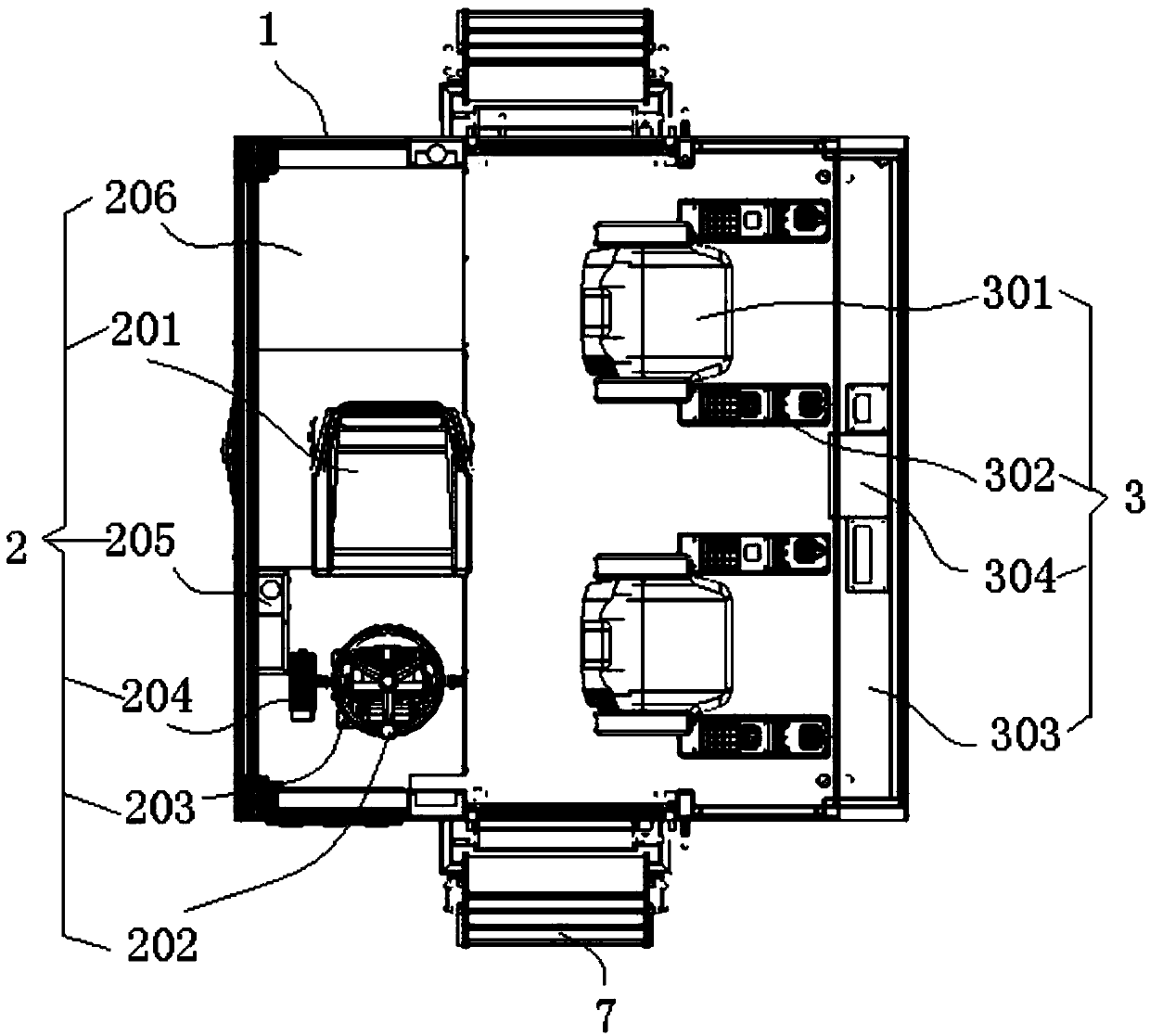

[0025] see figure 1 and figure 2 , figure 1 and figure 2 A specific embodiment of the cab of a rock drilling rig is provided, wherein, figure 1 It is a schematic diagram of the overall structure of a cab of a rock drilling rig disclosed in Embodiment 1 of the present invention; figure 2 It is a top view inside the bin body disclosed in Embodiment 1 of the present invention.

[0026] Such as figure 1 and figure 2 As shown, the present embodiment discloses a cab of a rock drilling jumbo, including a cabin body 1 , a driving control area 2 , a jib control area 3 , a support frame 4 and a jacking device 5 .

[0027] The bin body 1 is the main part of the cab of the rock drilling jumbo, and the actual size of the bin body 1 and the overall layout position on the outer car body are designed according to actual needs.

[0028] The cabin body 1 is provided with a driving control area 2 for vehicle driving control and a jib control area 3 for jib movement control. The drivi...

Embodiment 2

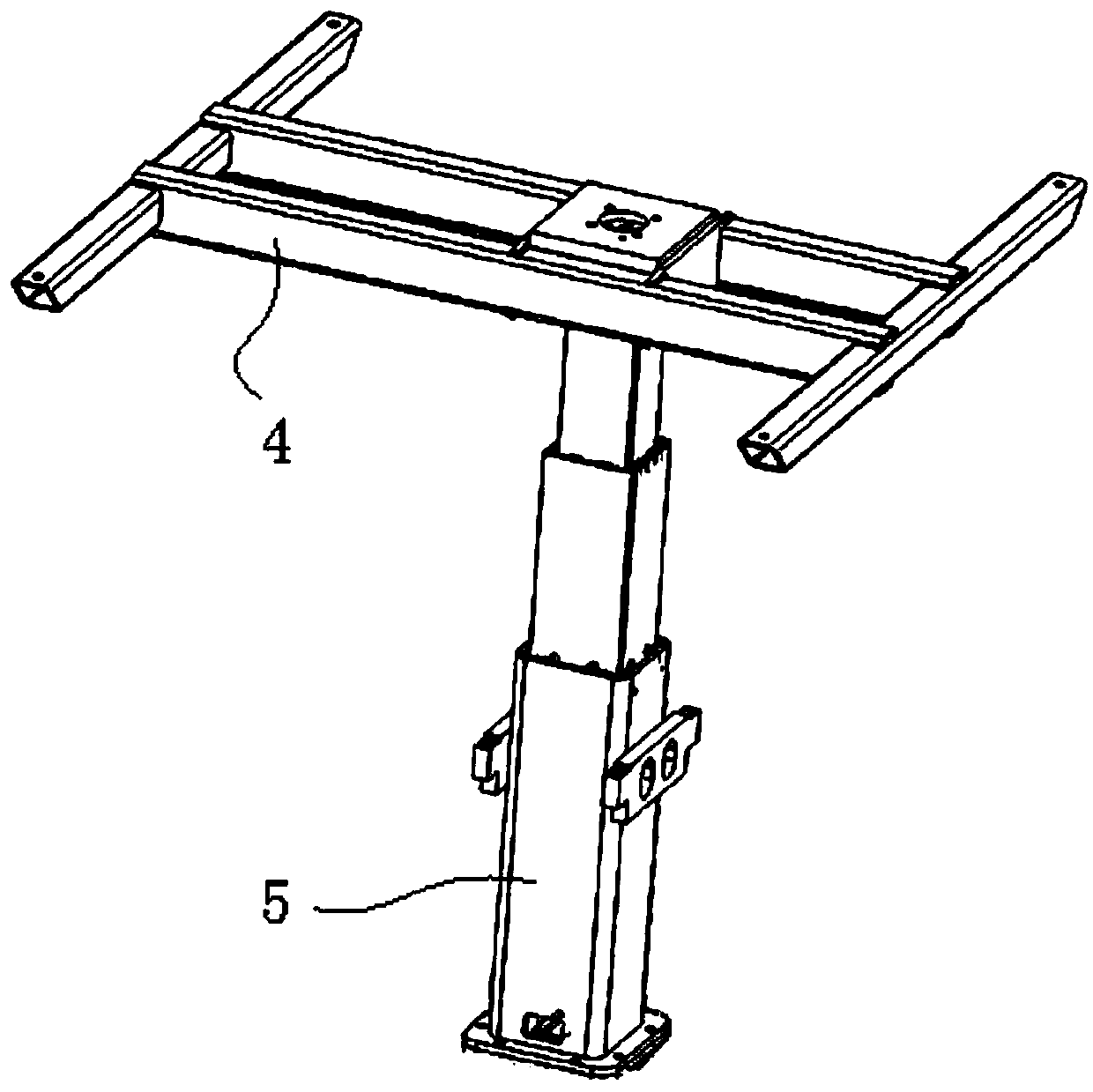

[0042] see Figure 3 to Figure 5 , Figure 3 to Figure 5 A specific embodiment of a jacking device is provided, wherein, image 3 It is a schematic diagram of the external structure of the jacking device disclosed in Embodiment 2 of the present invention; Figure 4 It is a schematic diagram of the internal structure of the jacking device disclosed in Embodiment 2 of the present invention; Figure 5 It is a schematic structural diagram of the spherical mechanism of the jacking device disclosed in Embodiment 2 of the present invention.

[0043] Such as Figure 3 to Figure 5 As shown, this embodiment provides a specific embodiment of a jacking device. The jacking device 5 includes a guide sleeve 501, a telescopic arm 502 slidingly arranged inside the guide sleeve 501, and a telescopic arm 502 arranged on the guide sleeve 501. The jacking cylinder 503 between the telescopic arm 502 , the lower end of the guide sleeve 501 is connected with the vehicle body, and the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com