A kind of forehearth molding and mixing process

A mixing process and forehearth technology, which is applied in the field of forehearth forming and mixing process, can solve problems such as bursting, delamination, and product streaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

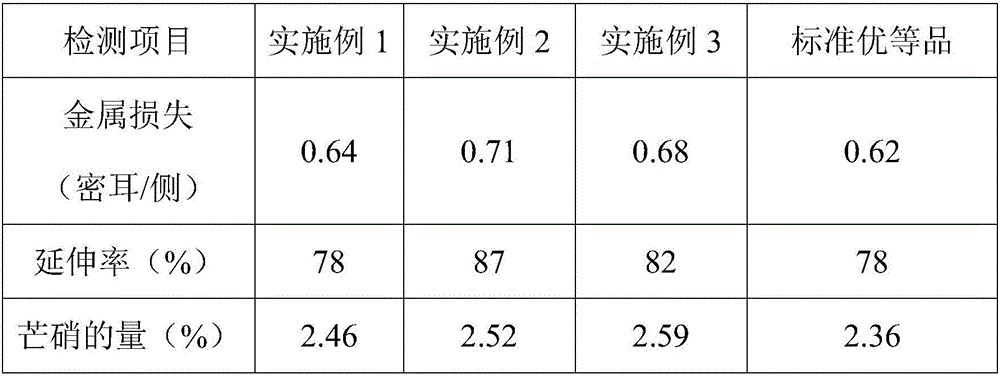

Examples

Embodiment 1

[0021] The process is carried out in four steps, first (1) preheating: heating the stirring paddle to 1000 °C, and then (2) installing material channel accessories: divided into three steps: cleaning material channel, installing accessories and inspection, among which cleaning material Clean the process with tap water twice, and install the accessories process to install the preheated stirring paddle in the material channel, and then carry out (3) feeding: it is divided into three steps: feeding, conditioning and feeding, in which the feeding process will use 10-30g The high borosilicate glass is fed into the feeder, the temperature is adjusted to 1100°C by the temperature adjustment process, 5g of additives are added by the feeding process, and then (4) molding treatment: divided into three steps: pressure adjustment, cooling and quenching, in which the pressure adjustment process adjusts the material The internal pressure of the tunnel is 1.10kpa, and the cooling process cool...

Embodiment 2

[0023] Carry out embodiment 1 repeatedly by the same steps as described, the difference is: in the step (1), the stirring paddle is heated to 1100 DEG C by preheating, in the step (2), the process of cleaning the forehearth is cleaned 3 times with tap water, and in the step ( 3) In the middle feeding process, 20g of high borosilicate glass is fed into the feeder, the temperature adjustment process adjusts the temperature to 1200°C, the feeding process adds 7g of additives, and the step (4) pressure adjustment process adjusts the internal pressure of the feeder to 1.14kpa, The cooling process cools down to 150°C at a cooling rate of 125°C / h.

Embodiment 3

[0025] Carry out embodiment 1 repeatedly by the same steps as described, the difference is: in the step (1), preheating stirrer is heated 1200 ℃, and in the step (2), the process of cleaning the forehearth is cleaned 3 times with tap water, and in the step (3) ) in the feeding process, 30g of high borosilicate glass is fed into the feeder, the temperature adjustment process adjusts the temperature to 1300°C, the feeding process adds 8g of additives, step (4) the pressure adjustment process adjusts the internal pressure of the feeder to 1.18kpa, and cools down The process cools down to 200°C at a cooling rate of 130°C / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com