Hand lay-up epoxy resin composition for wind power blades

An epoxy resin and wind power blade technology, applied in the field of wind turbine blades, can solve the problems of slow resin curing speed and affecting blade production efficiency, and achieve the effects of improving production efficiency, improving low-temperature curing performance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

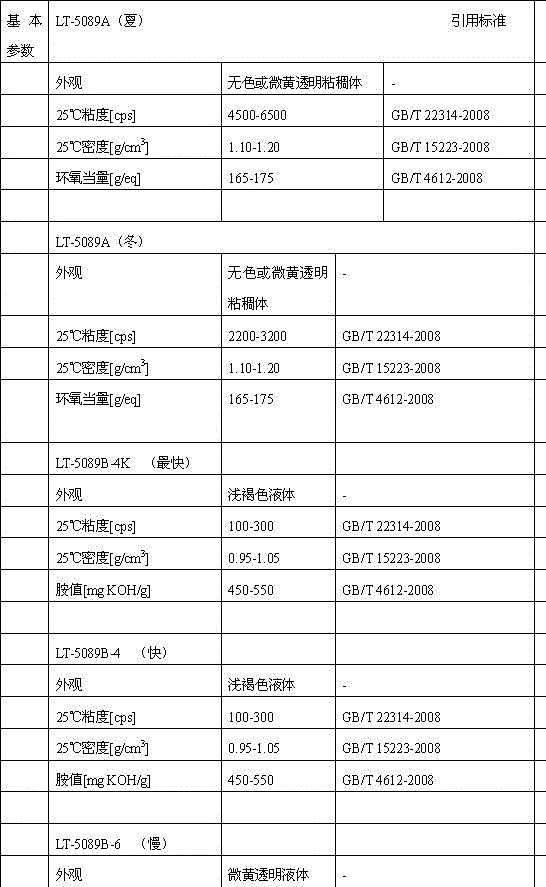

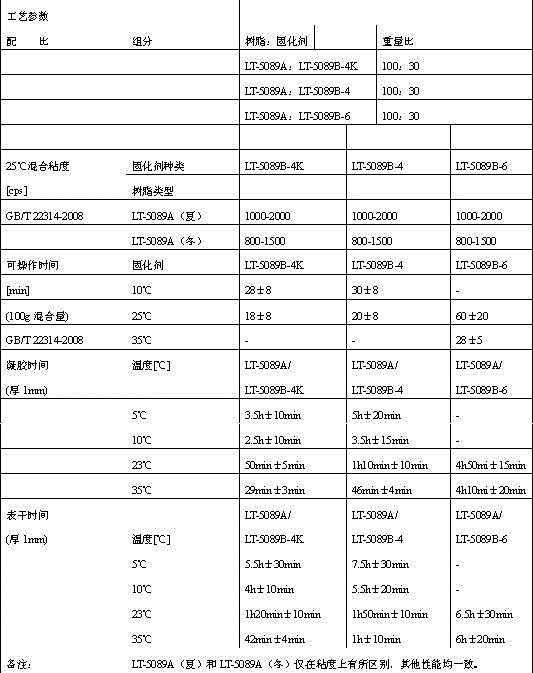

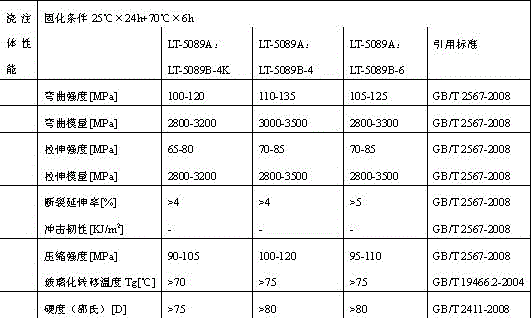

Image

Examples

preparation example Construction

[0043] Described a kind of preparation method of hand lay-up epoxy resin composition for wind power blades, it comprises each component of described proportion and following steps:

[0044] Step 1, prepare the resin component

[0045] a. Preheat bisphenol A epoxy resin 128 and epoxy diluent BDGE to 60°C-65°C;

[0046] b, add bisphenol A type epoxy resin 128 and part of epoxy diluent BDGE preheated in step 1 to the reactor;

[0047] c, adding bisphenol F type epoxy resin 170 to the reactor;

[0048] d, start the stirrer, and stop after stirring at a speed of 24-28rpm for 30-40min;

[0049] e, add the remaining epoxy diluent BDGE,

[0050] f. In a vacuum environment, start the stirring program, control the high speed 28 rpm, low speed 24 rpm, keep stirring for 60-90 minutes, and turn off the stirring program;

[0051] g, stop vacuuming, and return to normal pressure in the reactor to obtain the first component;

[0052] Step 2, preparing component B;

[0053] h, accurately...

Embodiment 1

[0058] Example 1 The curing agent 5089B-4k is used, that is, the amount of the tertiary amine accelerator K54 is 10%

[0059] Resin component: bisphenol A type epoxy resin 128 90%

[0060] Bisphenol F type epoxy resin 170 5%

[0061] Epoxy Thinner BDGE 5%; and

[0062] Curing agent component: Polyetheramine curing agent D230 50%

[0063] Polyamide 1250 20%

[0064] Phenalkamine curing agent T31 20%

[0065] And the 10% tertiary amine accelerator K54 of the above three components; (the same below, unless otherwise specified)

Embodiment 2

[0066] Example 2 The curing agent 5089B-4 is used, that is, the amount of the tertiary amine accelerator K54 is 8%

[0067] Resin component: bisphenol A type epoxy resin 128 80%

[0068] Bisphenol F epoxy resin 170 10%

[0069] Epoxy Thinner BDGE 5%; and

[0070] Curing agent component: Polyetheramine curing agent D230 30%

[0071] Polyamide 1250 35%

[0072] Phenalkamine curing agent T31 27%

[0073] Tertiary amine accelerator K54 8%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com