Pull rope type automatic cylinder locking mechanism with self-locking function

An automatic lock and function technology, which is applied to the fixation of guns, weapon accessories, offensive equipment, etc., can solve the problems of false unlocking of the lock, time-consuming and laborious use, and no device that restricts the retraction of the lock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

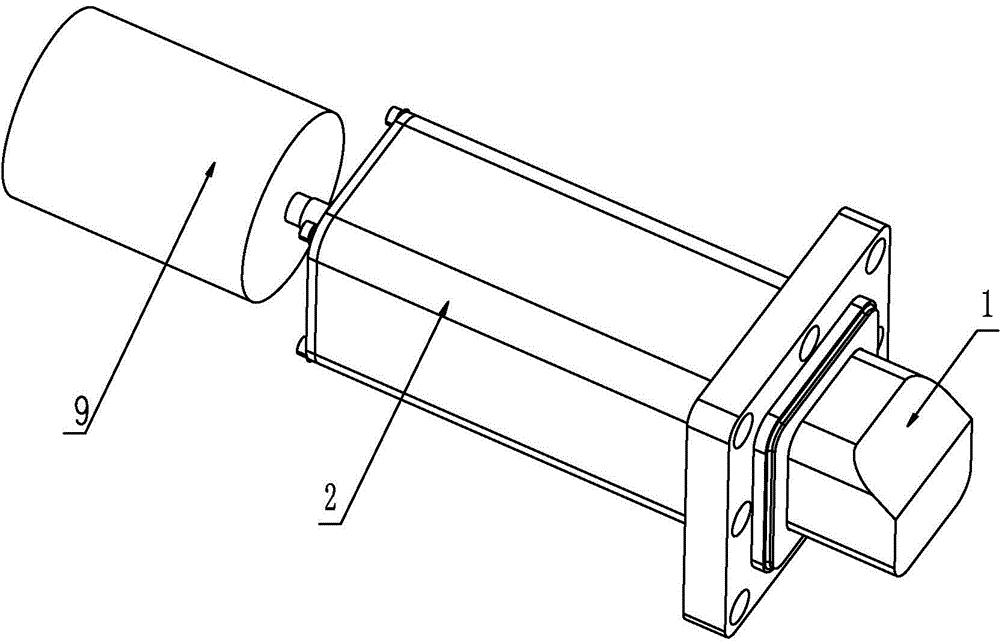

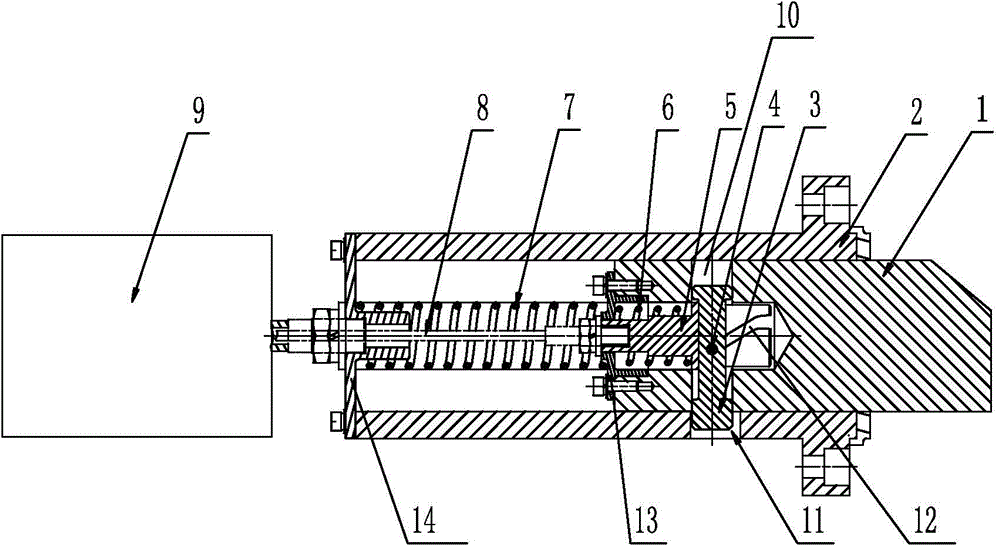

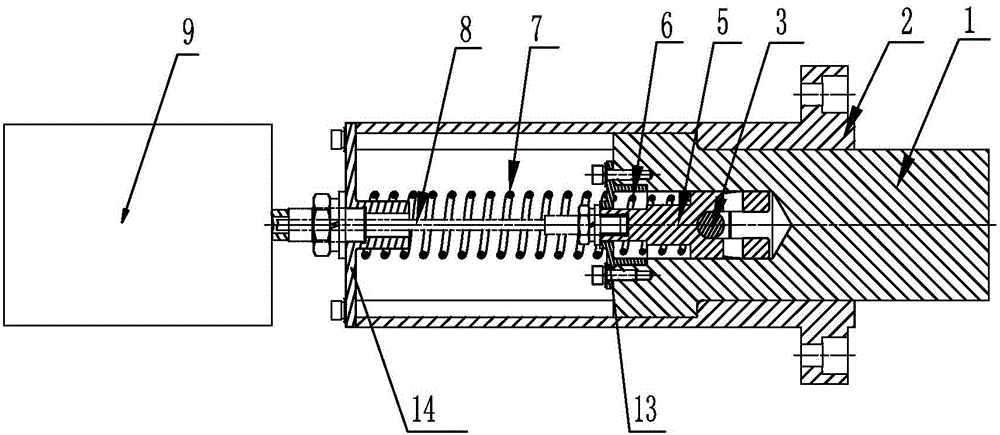

[0017] combine figure 1 , figure 2 and image 3 As shown, the pull cord type automatic locking cylinder mechanism with self-locking function of the present invention includes a lock head 1, a lock sleeve 2, a limit block 3, a guide pin 4, a pull rod 5, a pull rod spring 6, a lock head spring 7, and a pull cord 8 , the cylinder 9, the lock sleeve 2 is a hollow rectangle, the outer wall of the lock sleeve 2 is provided with a limit hole 11, the left end of the lock sleeve 2 is fixedly connected with a lock sleeve end cover 14 by bolts, the right end of the lock sleeve 2 is open, and the lock head 1 is arranged on the lock sleeve 2, the outer surface of the lock head 1 fits the inner surface of the lock sleeve 2, the left end of the lock head 1 is provided with a countersink hole along its longitudinal center, the left end of the countersink hole is fixedly connected with a gland 13 by bolts, and the lock head 1 The middle part near the left end is provided with a guide hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com