Molded case earth leakage circuit breaker

A plastic case type, leakage protection technology, applied in circuit breaker parts, circuit breaker contacts, switch terminals/connections, etc., can solve the problems of large overall size, unreasonable distribution of parts, increase manufacturing cost, etc. The time of arc striking, the effect of improving breaking capacity and avoiding temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

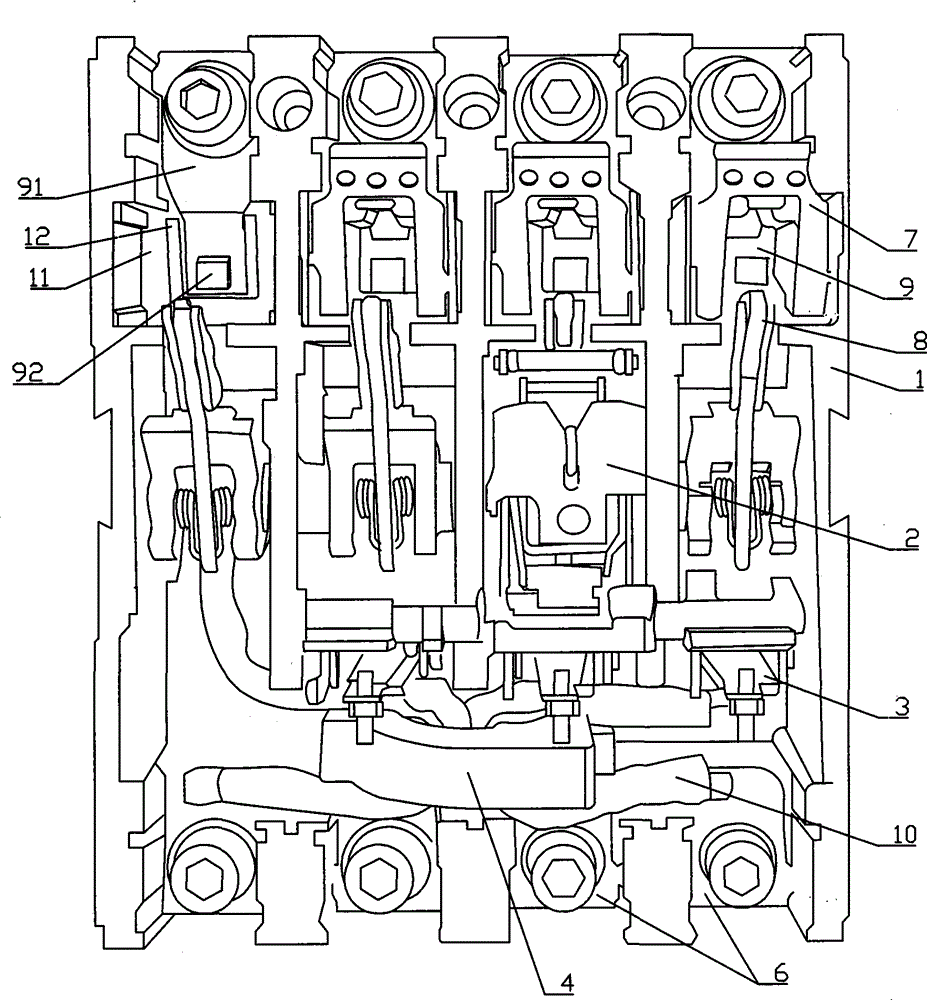

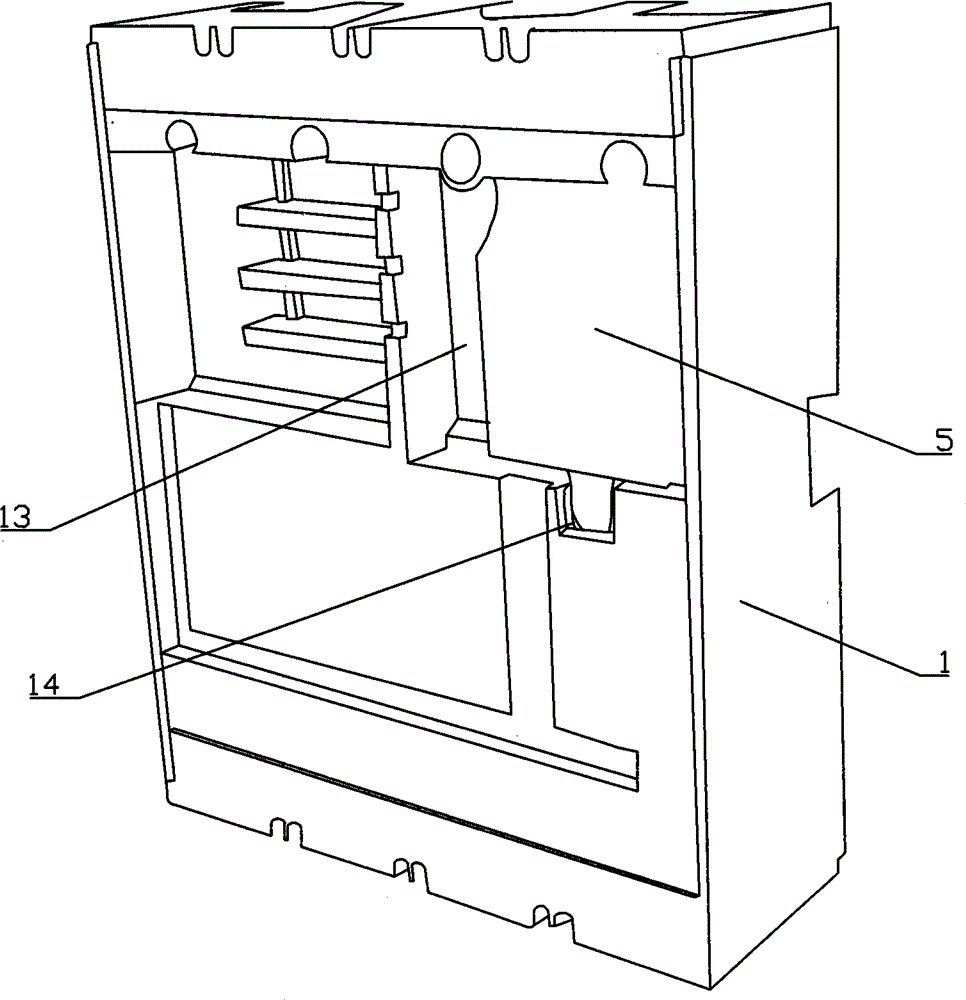

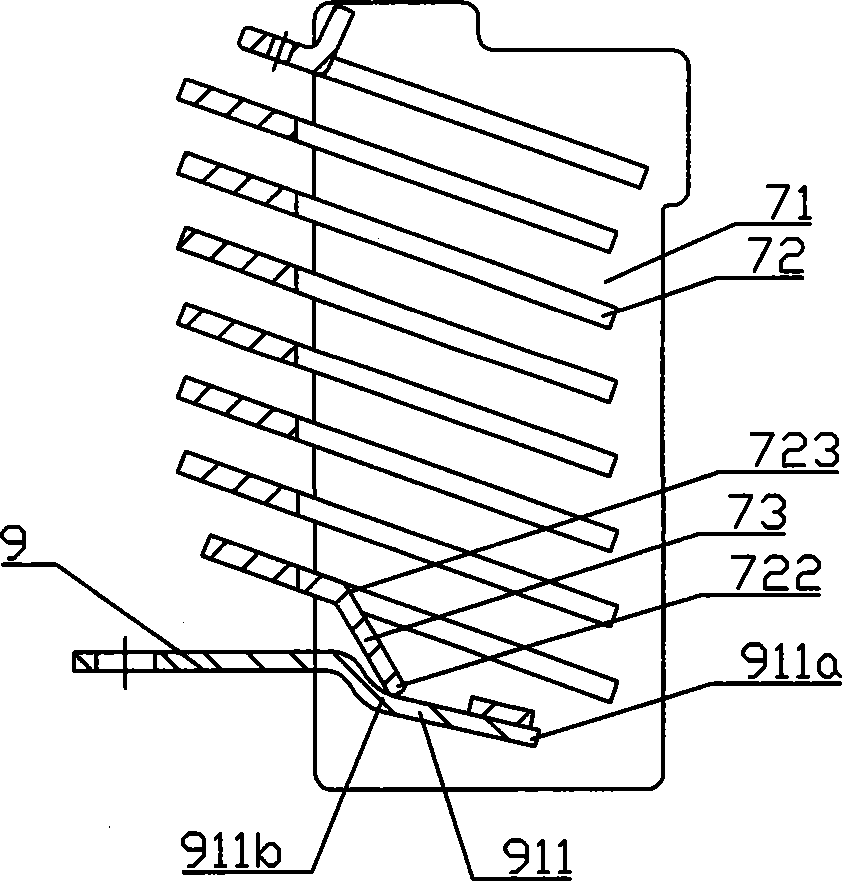

[0025] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-Figure 4 ;

[0026] The plastic case leakage protection circuit breaker given in this embodiment includes a base 1, an operating mechanism 2, a heating element 3, a transformer 4, a circuit board 5, a linkage release, a terminal 6, an arc extinguishing chamber 11, a Arc cover 7, moving contact 8 and static contact 9. Among them, the transformer 4 is used to detect the vector sum of the current. The transformer 4 is electrically connected to the circuit board 5 and the linkage release. When the current is too large, the heating element 3 bends. The connection terminal 6 , the operating mechanism 2 , the heating element 3 and the moving contact 8 are all installed on the base 1 . Structures such as the operating mechanism, thermal elements, transformers, and circuit boards all belong to the prior art, and will not be repeated here. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com