Brewing device for powdery drinks

A beverage and brewing technology, which is applied to the field of powder beverage brewing devices, can solve the problems of large error in the ratio of powder and water, waste, poor fluidity of milk powder, etc., and achieve the effect of stable brewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

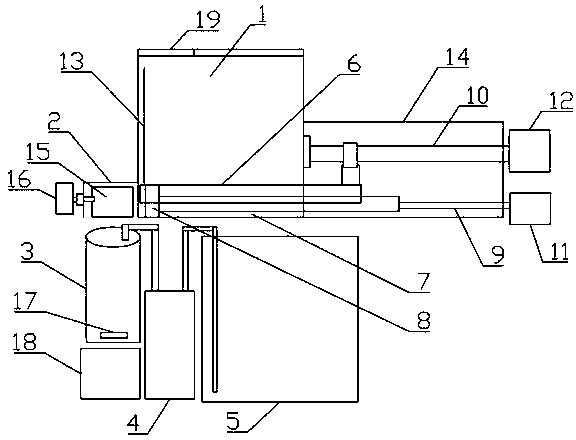

[0015] like figure 1 As shown, a powder beverage brewing device includes a powder box 1, the top of the powder box is provided with a box cover 19, the box cover is a double-layer structure, and a moisture-proof agent is placed in the interlayer between the double layers. It also includes a powder feeder matched with the powder box 1, including a sliding cover 6 opened at the bottom of the powder box, a powder applicator 13 is arranged on the sliding cover, and the powder dispenser is located in the powder box, and a bottom is provided under the sliding cover The slot 7 and the bottom slot are provided with a piston 8; the slide cover is linked with the slide screw 10, the slide motor 12 drives the slide screw, the piston 8 is linked with the piston screw 9, and the piston motor 11 drives the piston screw. Both the sliding cover lead screw and the piston lead screw are arranged in the lead screw dust cover 14 . A powder collecting cover 2 is arranged at the powder outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com