A heat pump system utilizing high temperature waste water source

A technology for heat pump systems and high-temperature wastewater, applied in heat recovery systems, heat pumps, energy-saving heating/cooling, etc., can solve the problems of not being well utilized, low utilization rate and thermal efficiency, etc., and achieve full utilization and increased energy efficiency ratio , the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

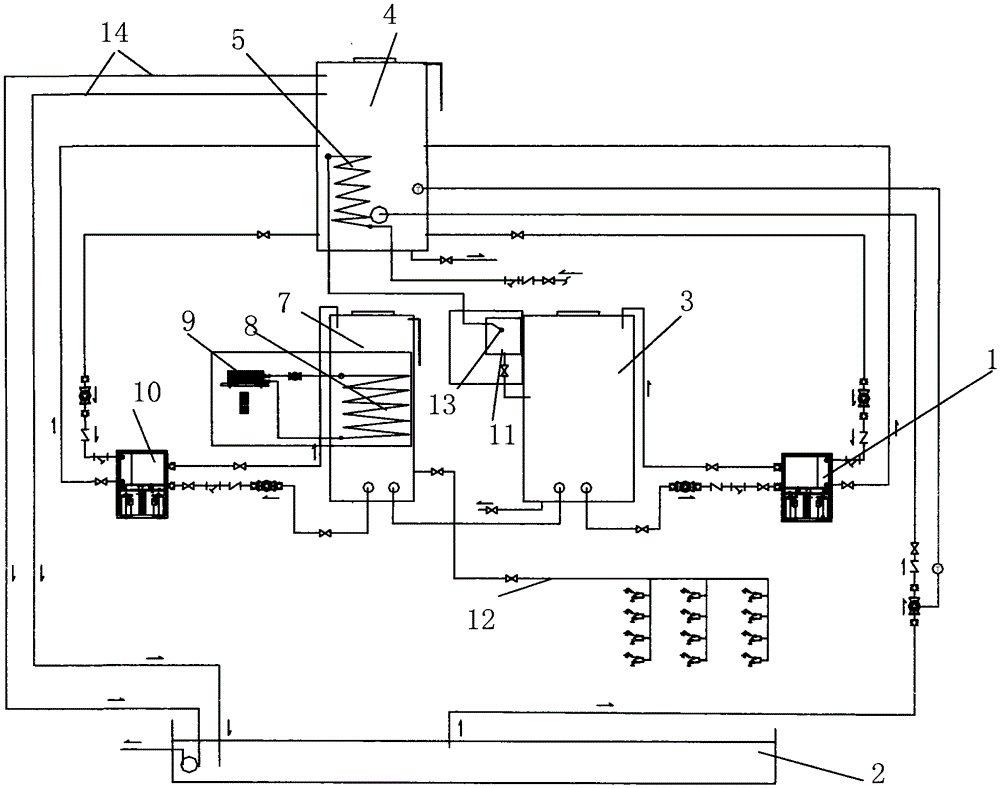

[0012] refer to figure 1 As shown, a heat pump system utilizing a high-temperature waste water source is provided, and a waste heat pool 2, a heat storage tank 3, a constant temperature water tank 7, and an energy-saving water storage tank 4 are provided, and the waste heat pool 2 is transported through pipelines and waste water The pump sends hot water to the energy-saving water storage tank 4, and the energy-saving water storage tank 4 sends the waste hot water to the first waste water source circulating heat pump unit 1 through two pipes and a delivery pump to form a circulation pipeline, and the first waste water source circulating heat pump unit 1 passes through The other two pipelines, the circulation pump and the hot water storage tank 3 form a hot water heating circulation pipeline; the hot water storage tank 3 sends the heated water to the constant temperature water tank 7;

[0013] The energy-saving water storage tank 4 also sends the waste hot water to a second wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com