An instrument assembly integrating wiring harness connectors

A technology of connectors and wire harnesses, which is applied in the field of instrument assemblies integrating wire harness connectors, can solve the problems of increasing the structural complexity of the instrument case 1, increasing the cost of the instrument, and affecting the instrument, so as to solve the problem of external water entering the instrument case In vivo, avoiding interference wear, avoiding the effect of water short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

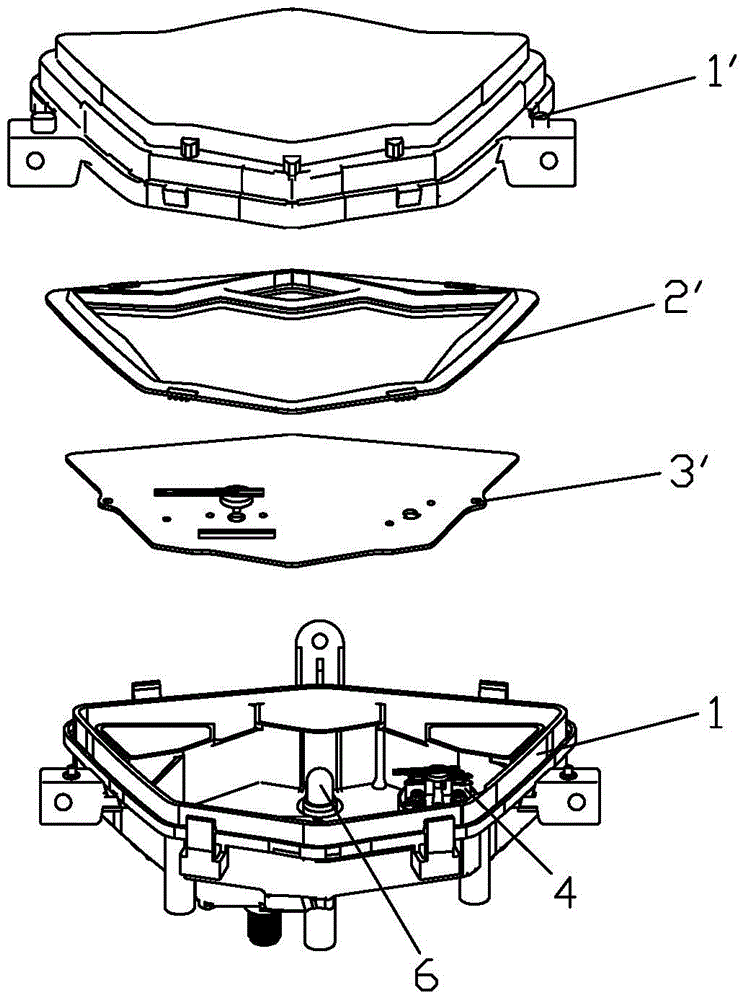

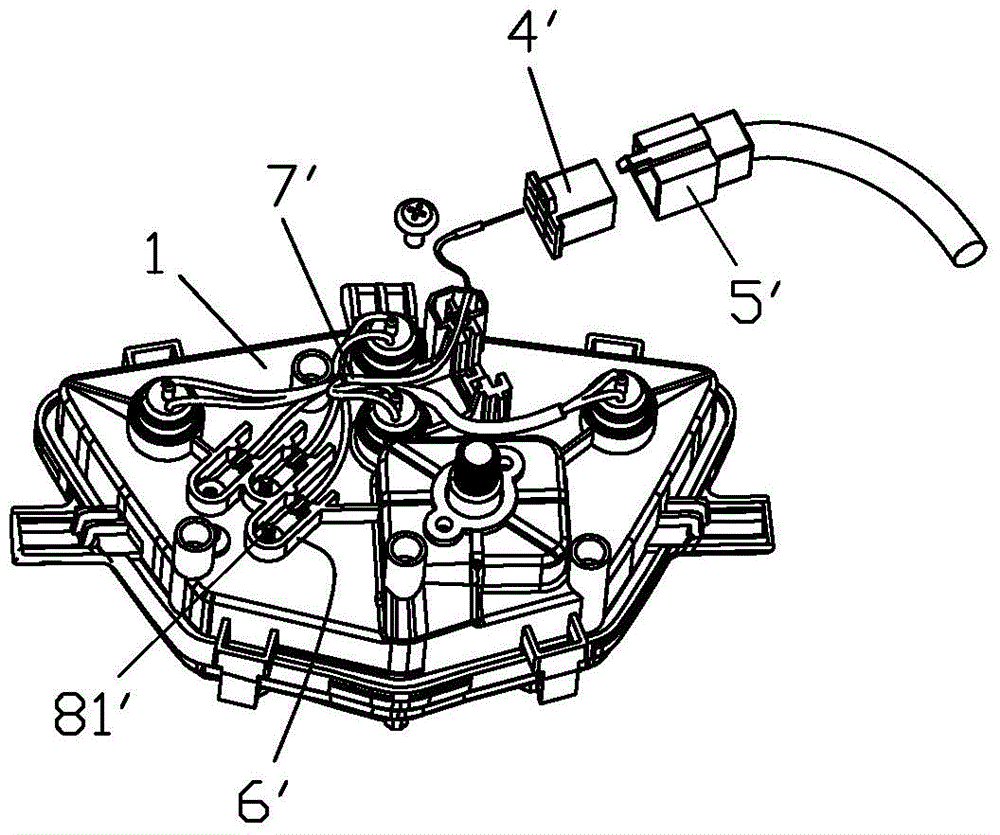

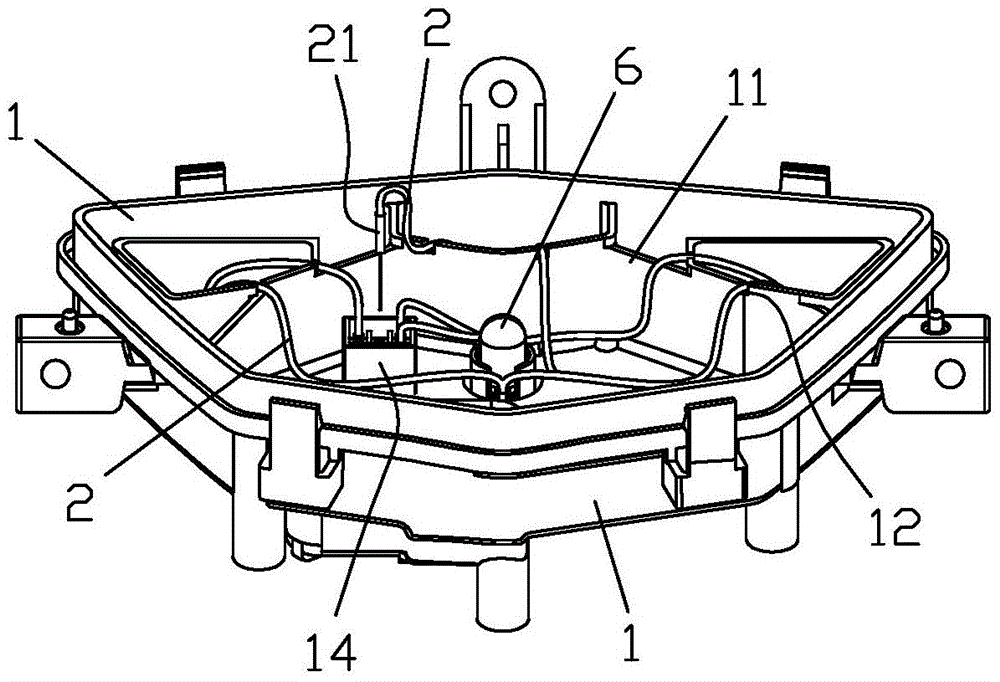

[0040] refer to Figure 1 to Figure 19 , an instrument assembly integrating wiring harness connectors according to the present invention, including an instrument case 1, in which electrical components are installed, and the electrical components include an oil gauge 4, a light bulb 6, an engine failure indicator light, and a battery indicator light etc., the electrical components are led out with wires 2, and the instrument housing 1 is integrally formed with a harness connector 3, the wires 2 are arranged inside the instrument housing 1, and the wires 2 are inside the instrument housing 1 connected to the wire harness connector 3.

[0041] The inner bottom wall of the meter housing 1 is generally protruded with a vertical plate 11 that separates the electrical components separately. In this embodiment, the end of the vertical plate 11 is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com