Lamp tube bending process and bending mechanism

A lamp and bending technology, which is applied in the field of lamp bending method and bending mechanism, can solve the problems of excessive requirements, lengthening the length of both ends of the lamp, and increasing tube consumption, so as to ensure the quality of the bend and reduce the Transmission process, the effect of reducing amplification errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the utility model is described in further detail:

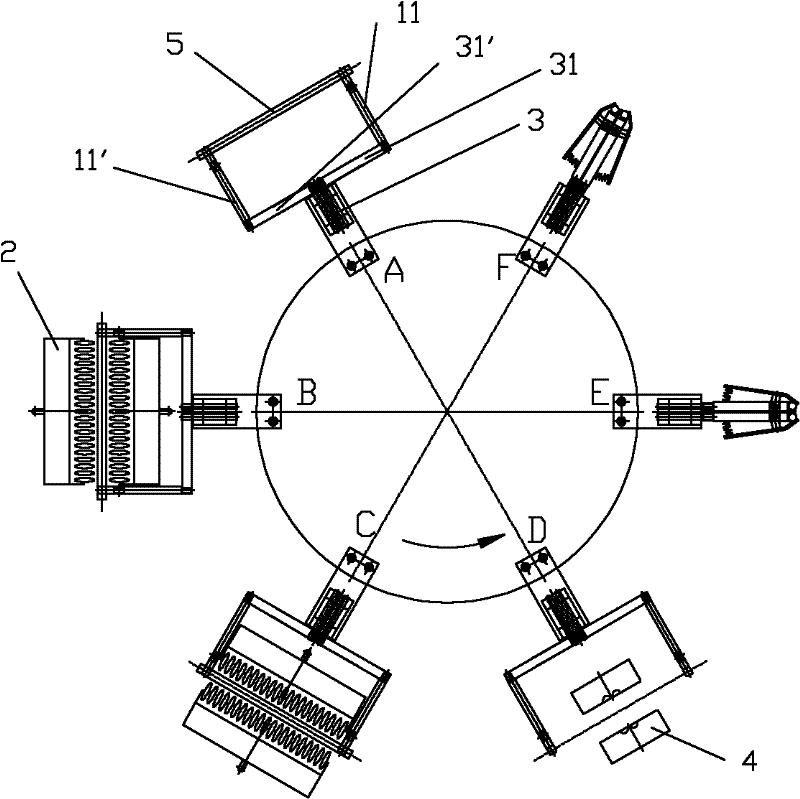

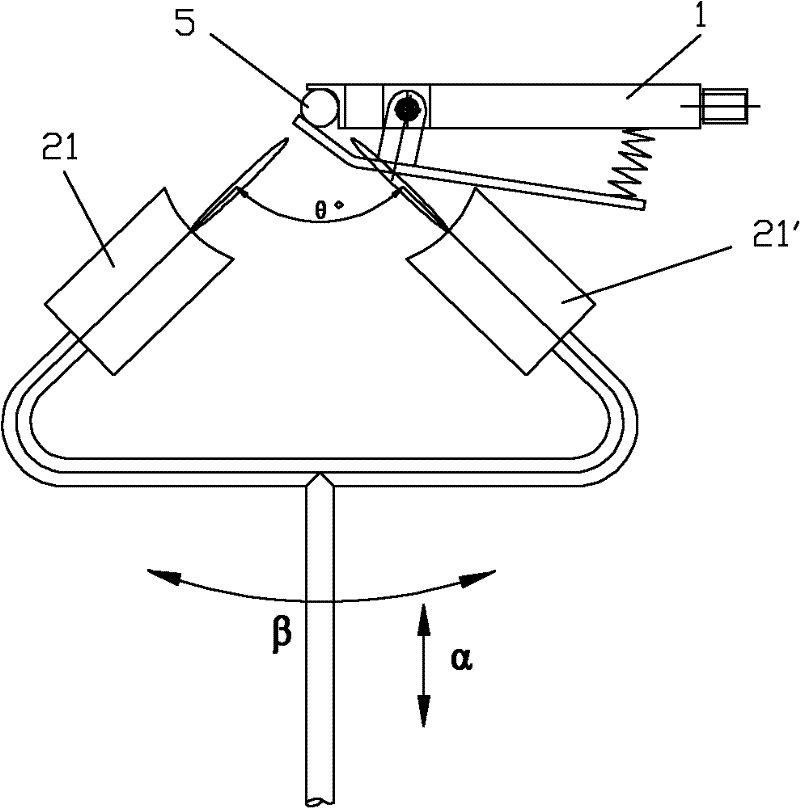

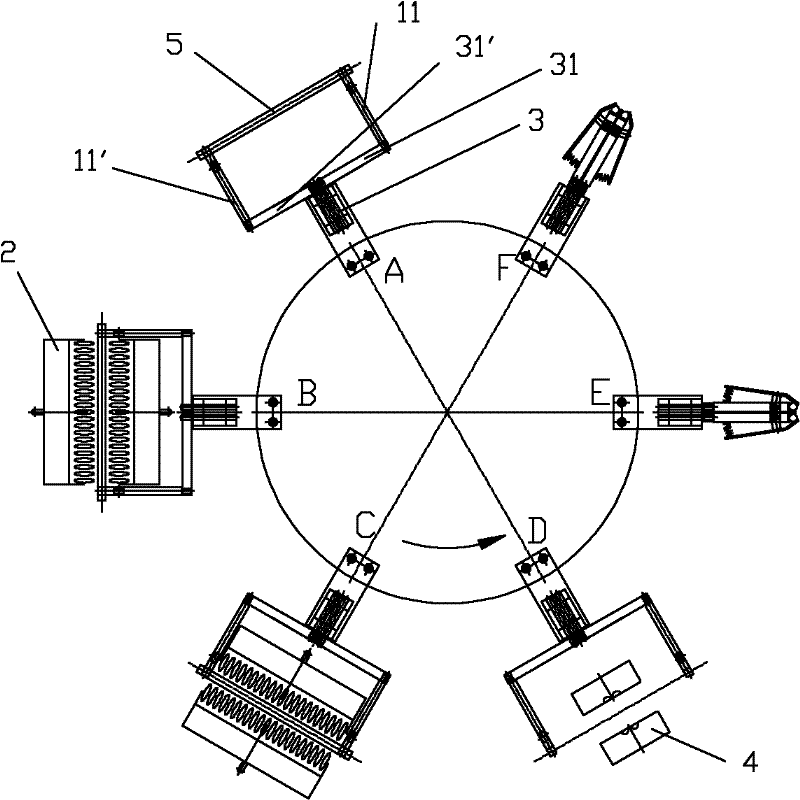

[0014] as attached figure 1 , the lamp tube bending mechanism of the present invention includes a burner 2, a bending device 3, a forming device 4, and a clamp 1; wherein the bending device 3 can be rotated and shifted in a gap, and can be in six positions: A, B, C, D, E, and F. Station, the bending device 3 is provided with bending arms 31, 31', and two clamps 11, 11' are respectively fixed on the bending arms 31, 31' to clamp the two ends of the lamp tube 5; the burner 2 for melting and softening the lamp tube is located The periphery of the lamp tube can also rotate around the lamp tube. The burner 2 has an array, and is located side by side at the periphery of the lamp tube 5 respectively. figure 2 As shown, each group of fire heads is composed of two fire heads 2, which are vertically arranged with the lamp tube 5, and can move radially close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com