Method for manufacturing hyperfine transistor by using thin film layer

An ultra-fine, thin-film layer technology, applied in nanotechnology for materials and surface science, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of difficult control of cost and quality, and achieve easy industrial production and simple operation , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] For a better understanding of the present invention, the following examples are further descriptions of the present invention, but the content of the present invention is not limited to the following examples.

[0041] The transfer, etching, deposition methods, substrates and substrates involved in the present invention are all prior art, which do not belong to the innovation of the present invention, and are only used here. The etching method includes but not limited to oxygen plasma etching, hydrogen plasma etching and the like. Transfer includes but is not limited to dry transfer or wet transfer, etc. Deposition methods include but are not limited to atomic layer deposition, chemical vapor deposition, magnetron sputtering, electron beam deposition, pulsed laser deposition, physical vapor deposition, and the like.

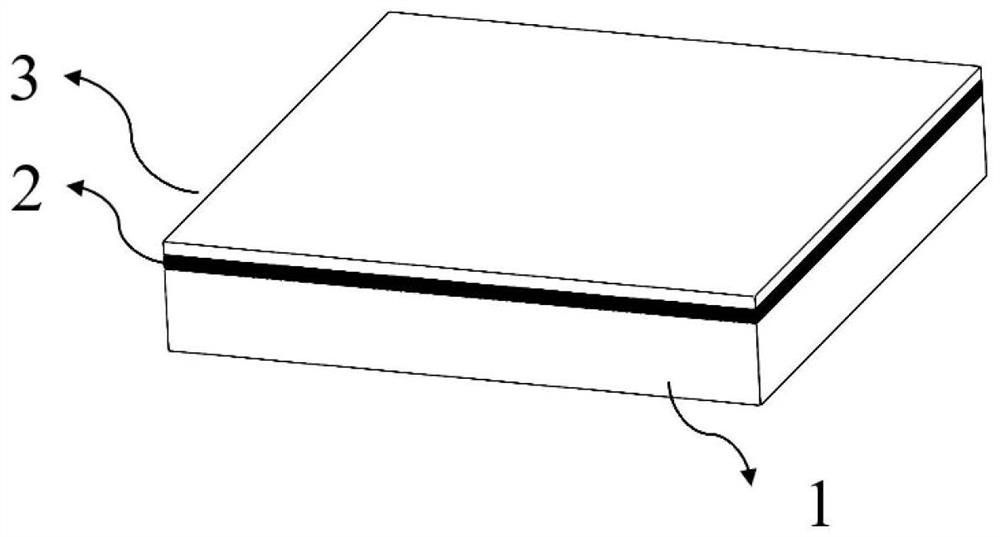

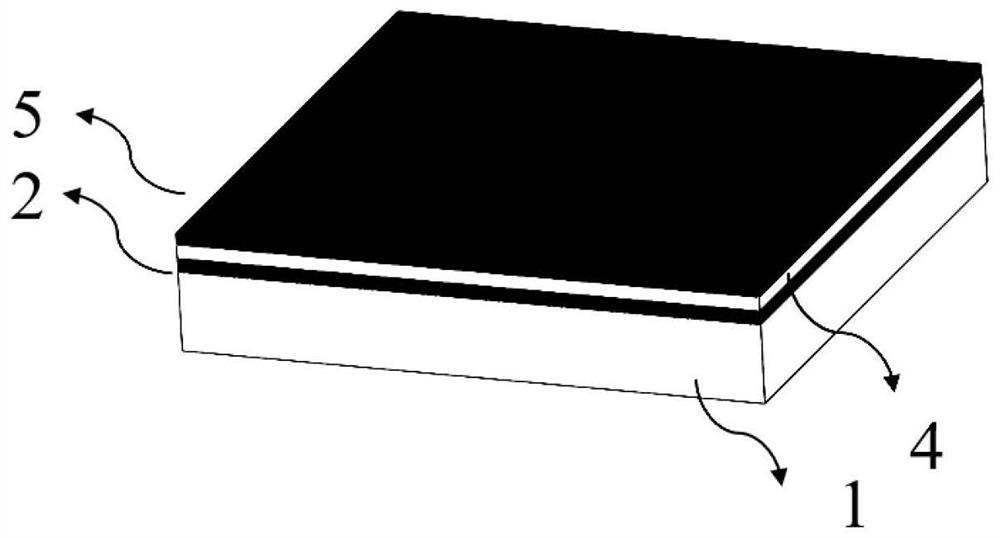

[0042] (1) repeatedly cleaning the sapphire substrate 1 in acetone, alcohol, deionized water and drying with nitrogen;

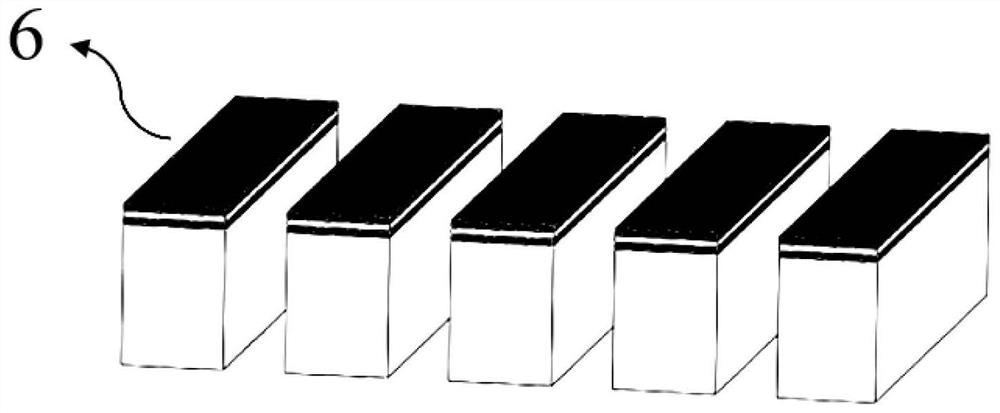

[0043] (2) using physical vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com