Yarn pressing device fast to assemble and disassemble

A yarn pressing device and yarn pressing technology, which is applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problem of time-consuming maintenance and other problems, and achieve the effect of simple and rapid assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

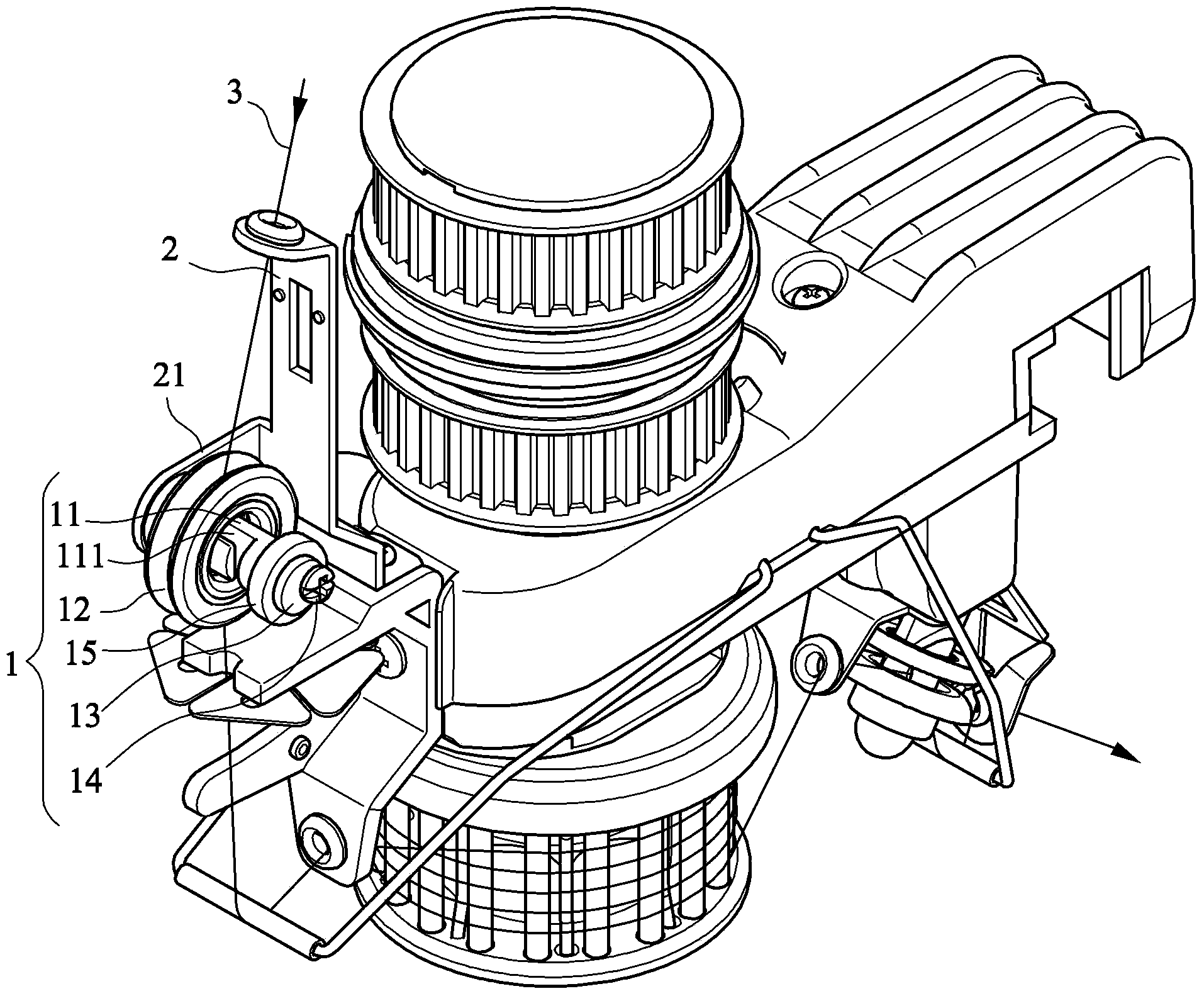

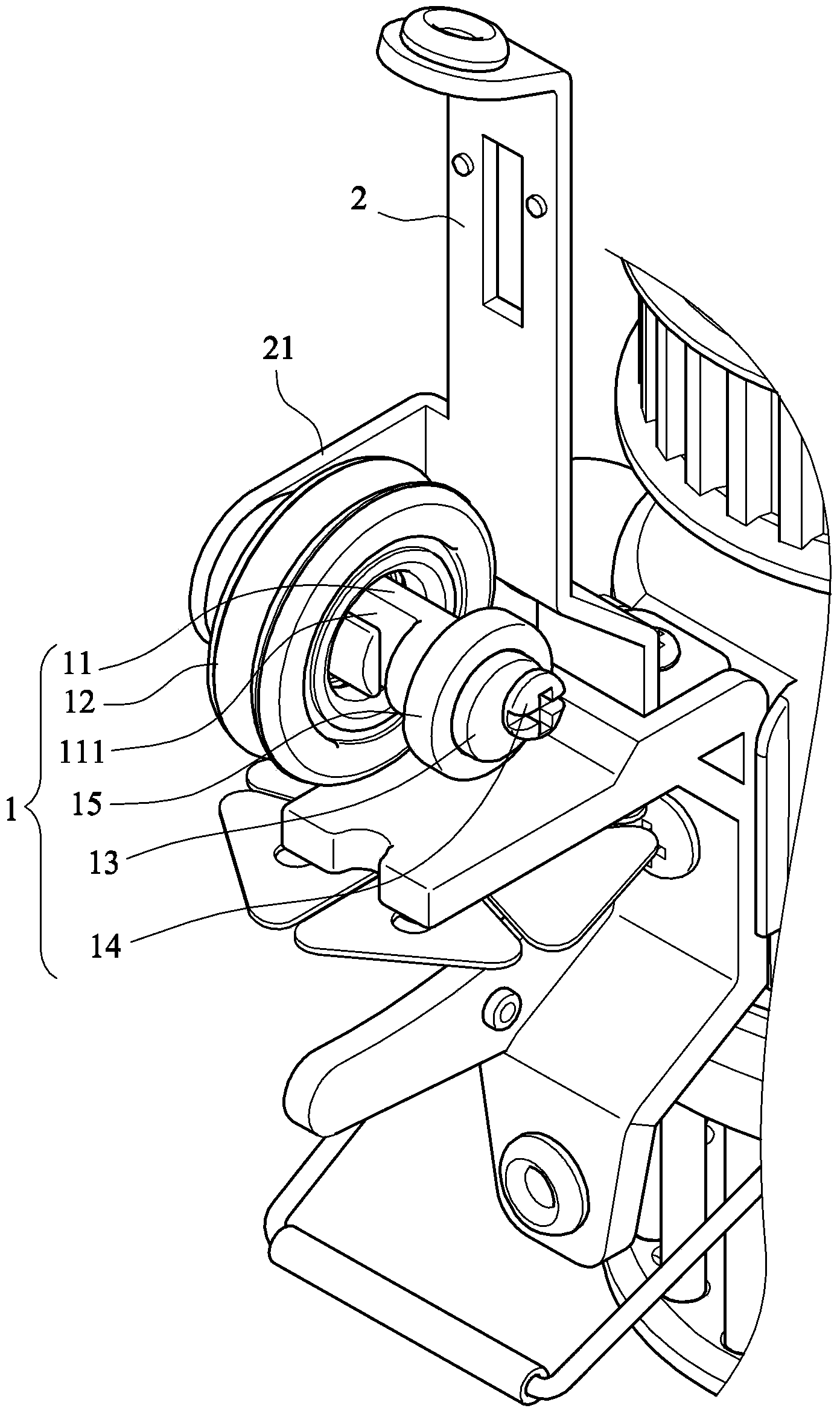

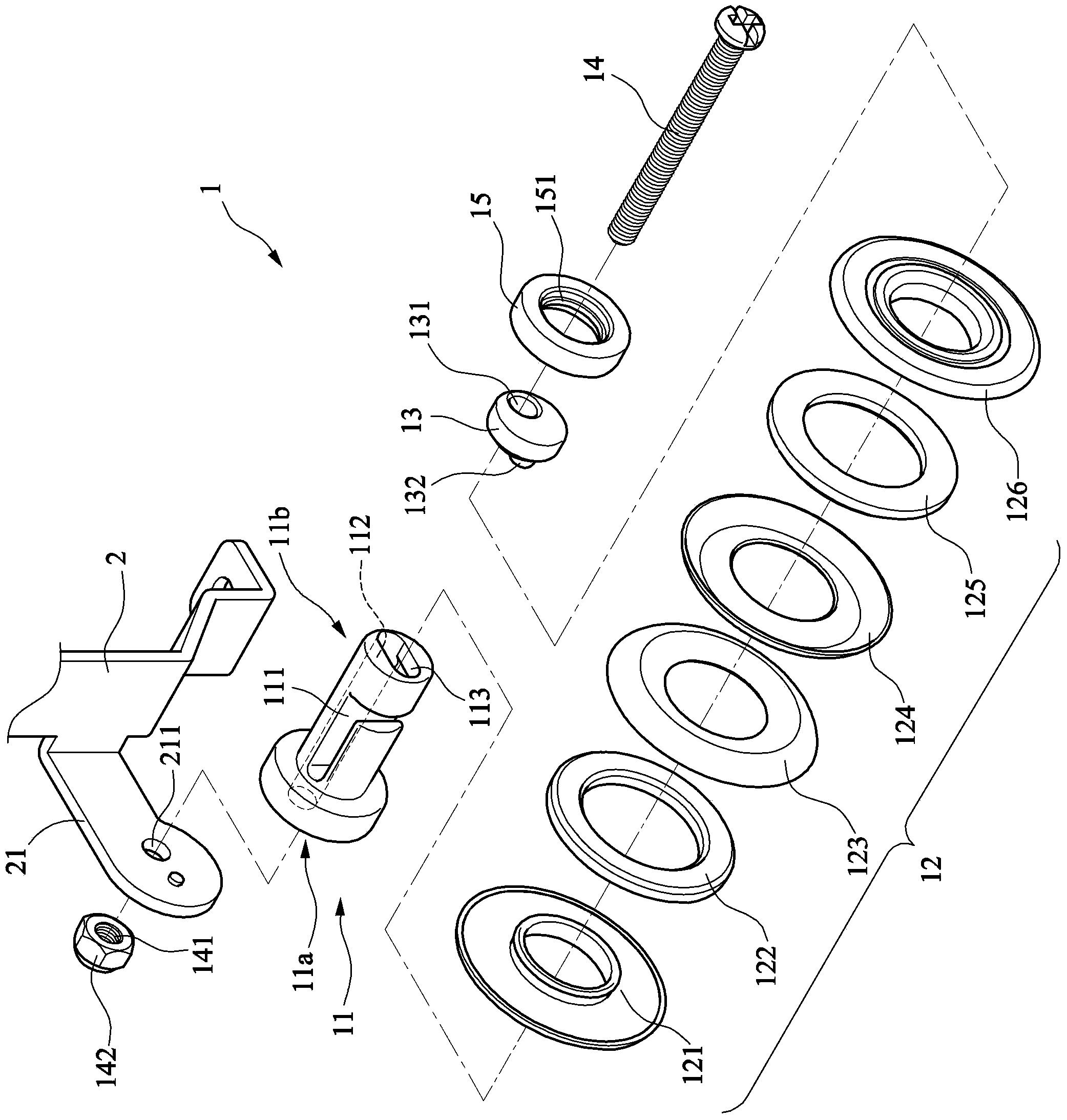

[0024] see Figure 1 to Figure 6 , the present invention provides a quick assembly and disassembly yarn presser for the yarn feeding device, the yarn presser 1 is set inside the extension plate 21 of the yarn seat 2 (or the yarn output and entry seats not shown in the figure), and The extension plate 21 is provided with a first through hole 211 and a nut 142 located outside the extension plate 21 (see image 3 ), the yarn presser 1 includes a yarn press post 11 , a yarn press disc set 12 , a cover 13 , a stud shaft 14 and a stop ring 15 .

[0025] The yarn pressing column 11 is a convex cylinder vertically fixed on the inner side of the extension plate 21, includes a large diameter portion 11a and a small diameter portion 11b, and has a yarn threading groove 111 and a second through hole 112 opening outward, And the outer end of the second through hole 112 is provided with a long groove 113 .

[0026] The yarn pressing disc 12 is set outside the yarn pressing column 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com