Connector

A joint and crossbar technology, applied in the field of joints, can solve the problems of easy wear and tear, complex structure, loss, etc., and achieve the effects of long service life, increased stability and firmness, and not easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

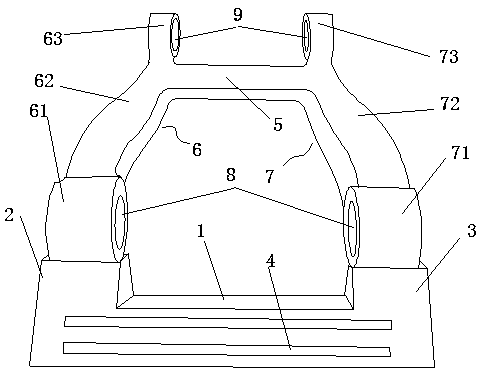

[0016] like figure 1 As shown, a combination piece includes a bottom and a connection part connected to the bottom. The connection part is arranged on the upper part of the bottom and connected to the bottom, which together constitute the whole of the combination piece and realize the purpose of combining various parts. The bottom includes a first cross bar 1 and first protrusions 2 and second protrusions 3 arranged at both ends of the first cross bar 1 , preferably the first protrusions 2 and second protrusions 3 at both ends of the first cross bar 1 Symmetrical arrangement, the symmetrical arrangement is convenient to manufacture, and the force is uniform, the first cross bar 1 is provided with a reinforcing rib 4, one end of the reinforcing rib 4 is connected to the first bump 2, and the other end of the reinforcing rib 4 is connected to The design of the second bump 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com