Thin film rotary cutter honing machine and honing method

A honing machine and cutting tool technology, which is applied in honing machine tools, manufacturing tools, grinding workpiece supports, etc., can solve the problems of cutting tools that cannot cut films, unstable quality, time-consuming and labor-intensive problems, etc., to improve the smoothness, improve the The effect of film product quality and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

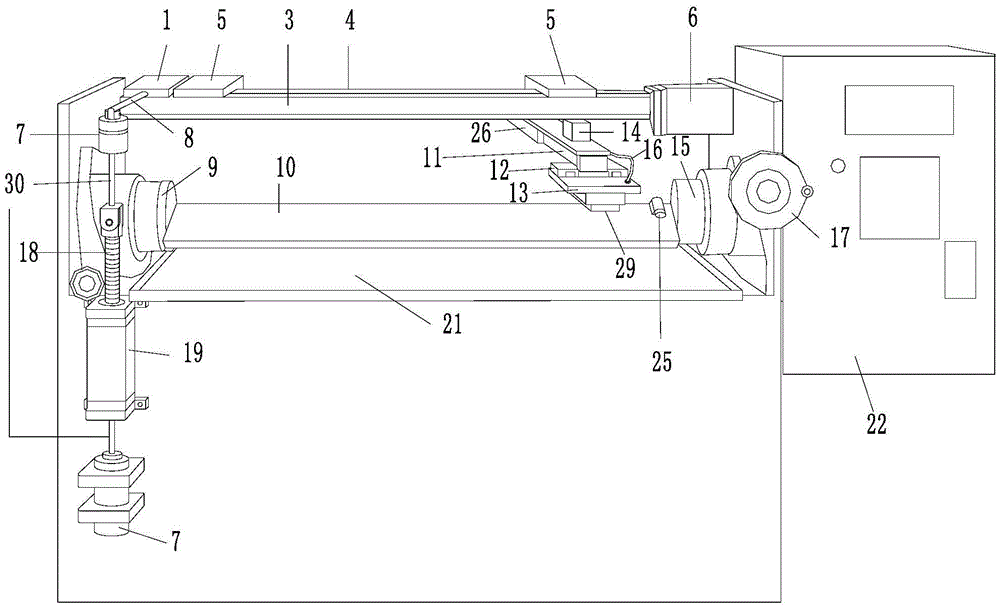

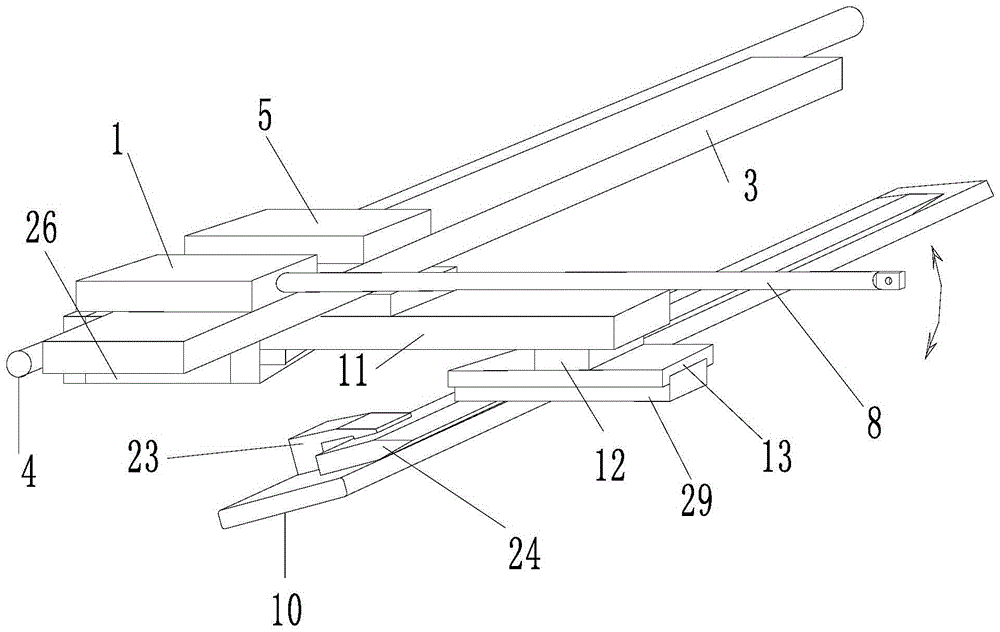

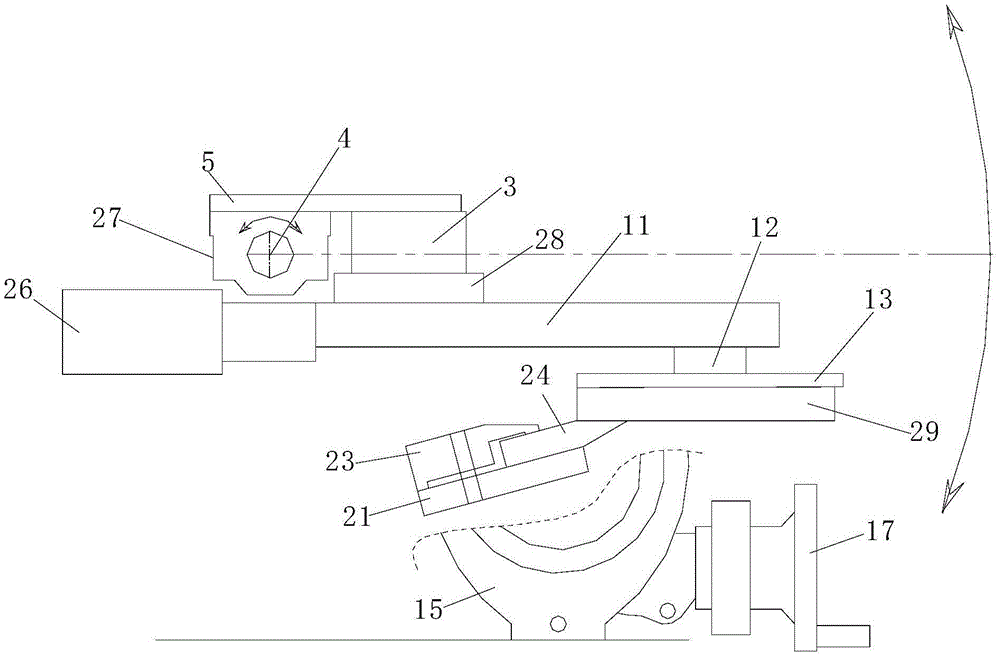

[0028] See Figure 1 to Figure 4 ,

[0029] A thin film rotary cutting tool honing machine includes a tool holder 10 on which a tool clamping plate 23 is installed,

[0030] The two ends of the tool holder are respectively mounted on the chuck 9 and the index plate 15. The chuck and the index plate are arranged coaxially, and the index plate is also installed with a corrugated hand wheel 17 and a corrugated hand wheel. The axis is located in the tangential direction of the index plate. The rotation of the index plate is driven by the rotation of the corrugated hand wheel. The chuck is installed on the left side plate of the frame, and the index plate is installed on the right side plate of the frame;

[0031] The XY platform support shaft 4 is also installed between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com