Folding rearview mirror for motor vehicles

A technology for rearview mirrors and motor vehicles, which is applied to vehicle components, installation, optics, etc., can solve the problems of complex configuration and high energy consumption, and achieve the effects of reducing consumption, avoiding friction, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

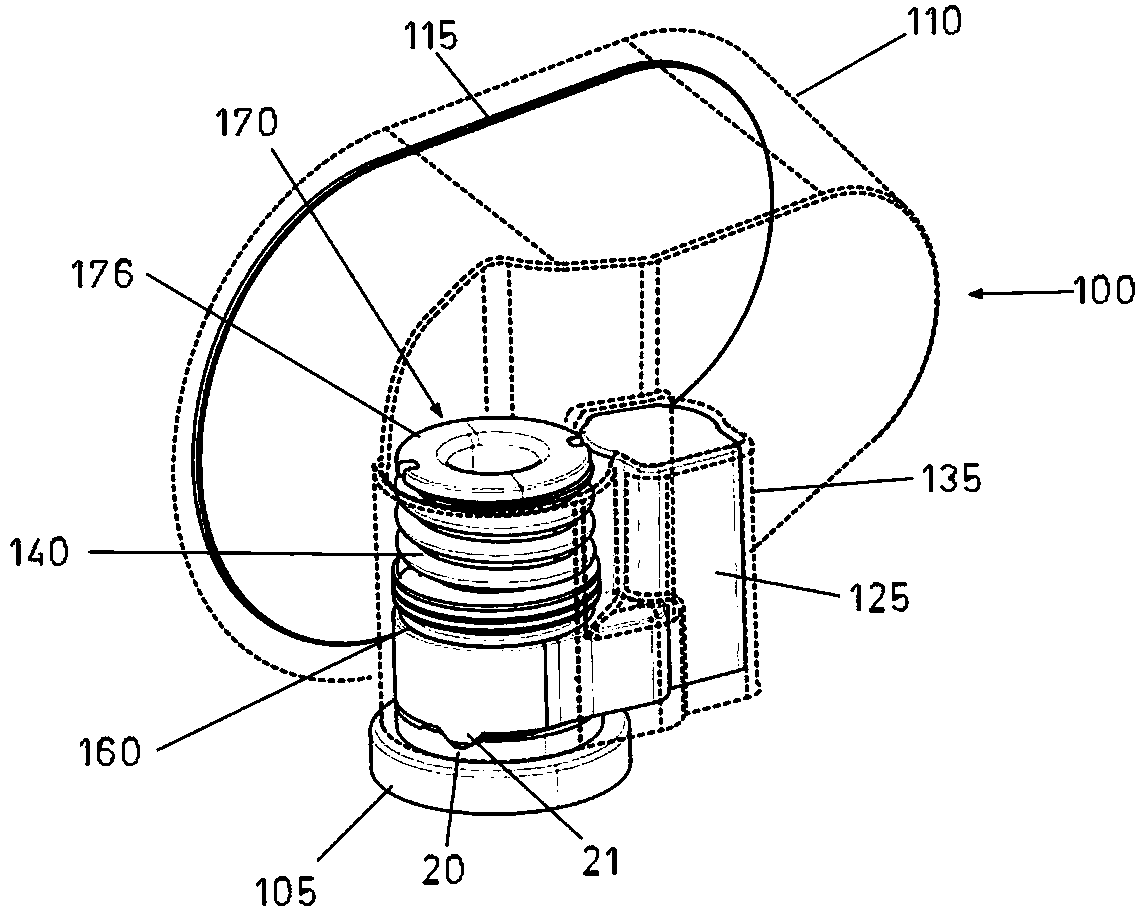

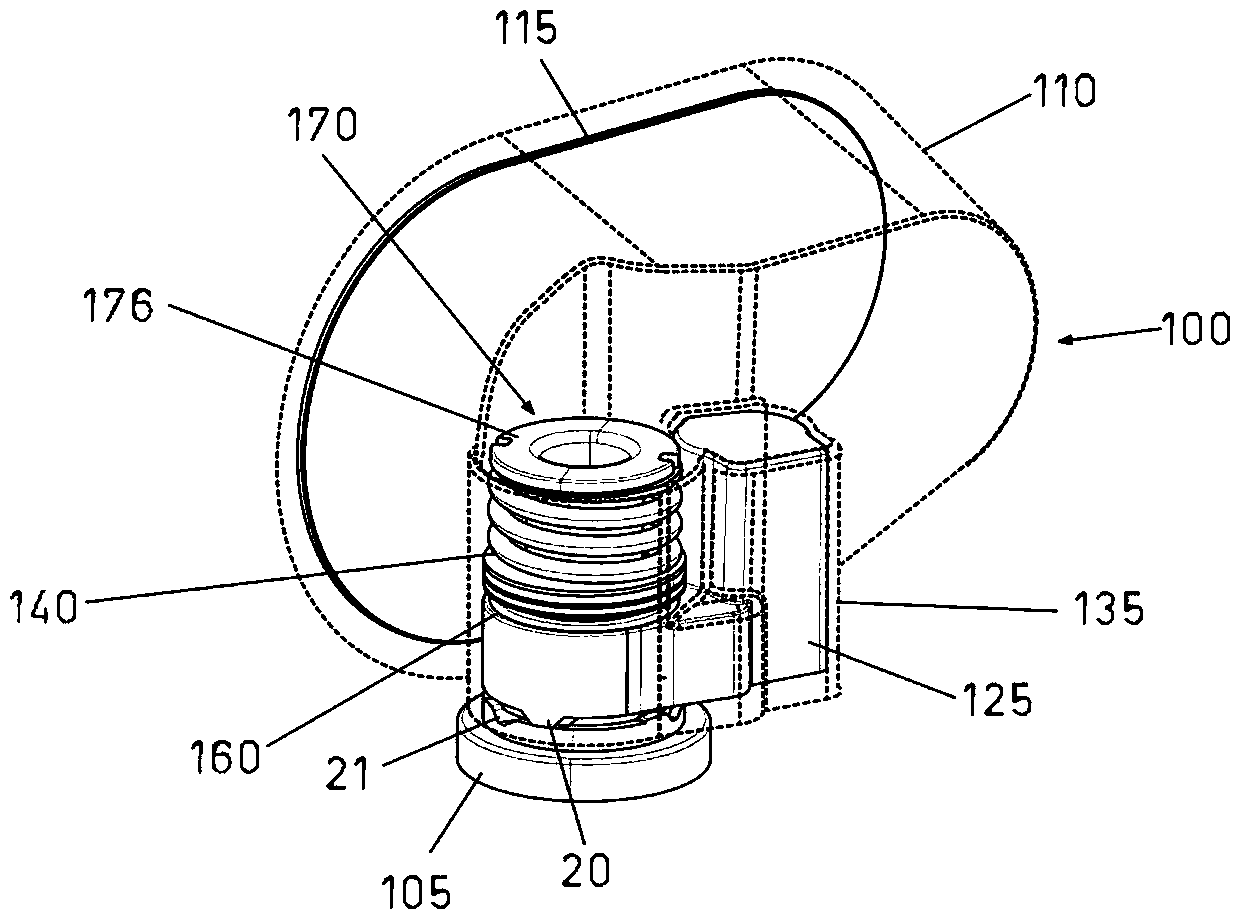

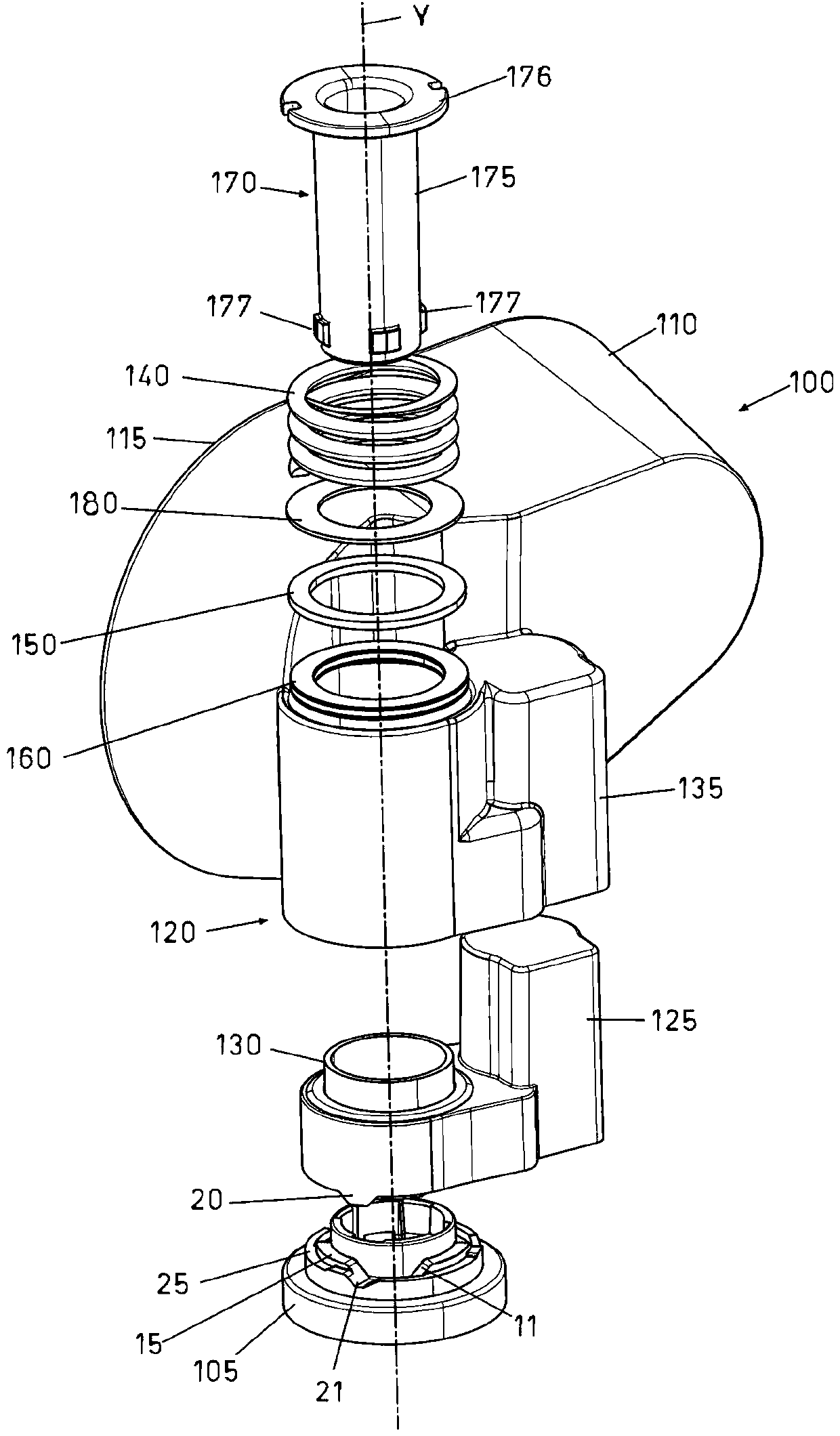

[0032] An example of a foldable mirror for a motor vehicle is shown in the accompanying drawings. In said figures, this mirror has generally been indicated by the reference numeral 100 .

[0033] The rearview mirror 100 includes a base element or base 105 . The base element 105 is adapted to be mounted and fixed on the exterior of the main body of the motor vehicle (at a position suitable for viewing while driving).

[0034] The rearview mirror 100 also includes a housing 110 . The housing 110 is mounted such that it can rotate relative to the base element 105 . Mirror element 115 is received in housing 110 .

[0035] On the opposite side where the mirror element 115 is arranged, the housing 110 has a recess 135 associated with the housing 110 for the motor part 120 . The motor assembly 120 is adapted to operate in a mirror operating position (such as figure 1 shown) with the mirror non-operating position (as figure 2 As shown, the housing 110 of the rearview mirror is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com