Eccentric type solid beating-up shaft device

A technology of eccentric beating shaft and eccentric type, applied in the field of eccentric solid beating shaft device, can solve the problems of lower loom efficiency, eccentricity of solid beating device, large vibration, etc., and achieve improved loom efficiency, stable operation, and rigidity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

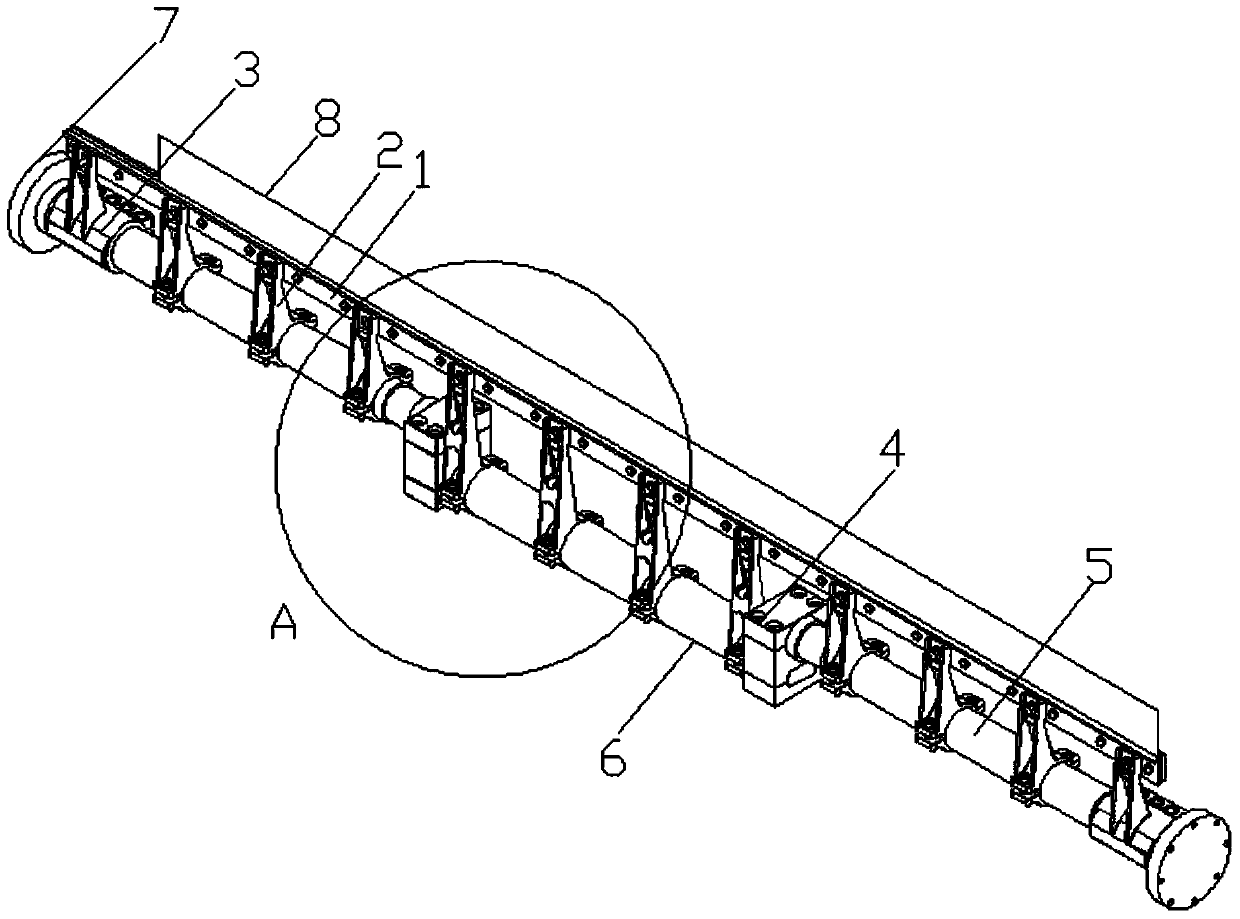

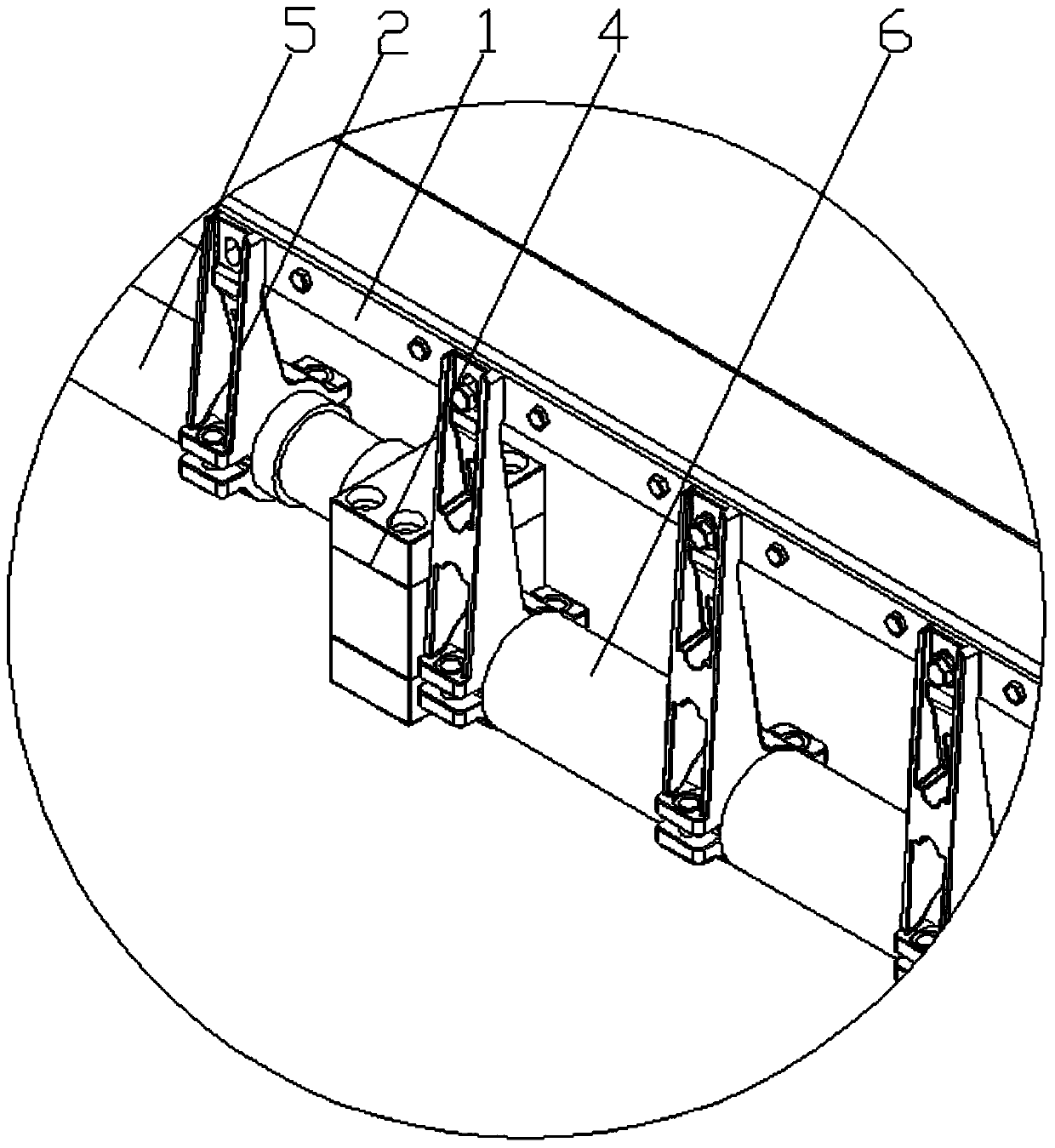

[0020] according to Figures 1 to 2 , the present invention provides an eccentric solid beating shaft device comprising a solid beating shaft, a steel reed 1, several sley feet 2, two shaft heads 3 located at the ends of the beating shaft, two The connection seat 4 in the middle part of the latitude axis. Steel reed is fixed on the loom heald frame 8, is used for fixing warp yarn and extruding weft yarn when beating up. Both the sley foot and the shaft head seat are connected with the reed by bolts. The sley feet are used to support the beat-up shaft, and are evenly spaced along the axial direction of the beat-up shaft.

[0021] The use of a solid beating shaft improves the rigidity of the invention, increases the beating strength, and is suitable for weaving high-density h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com