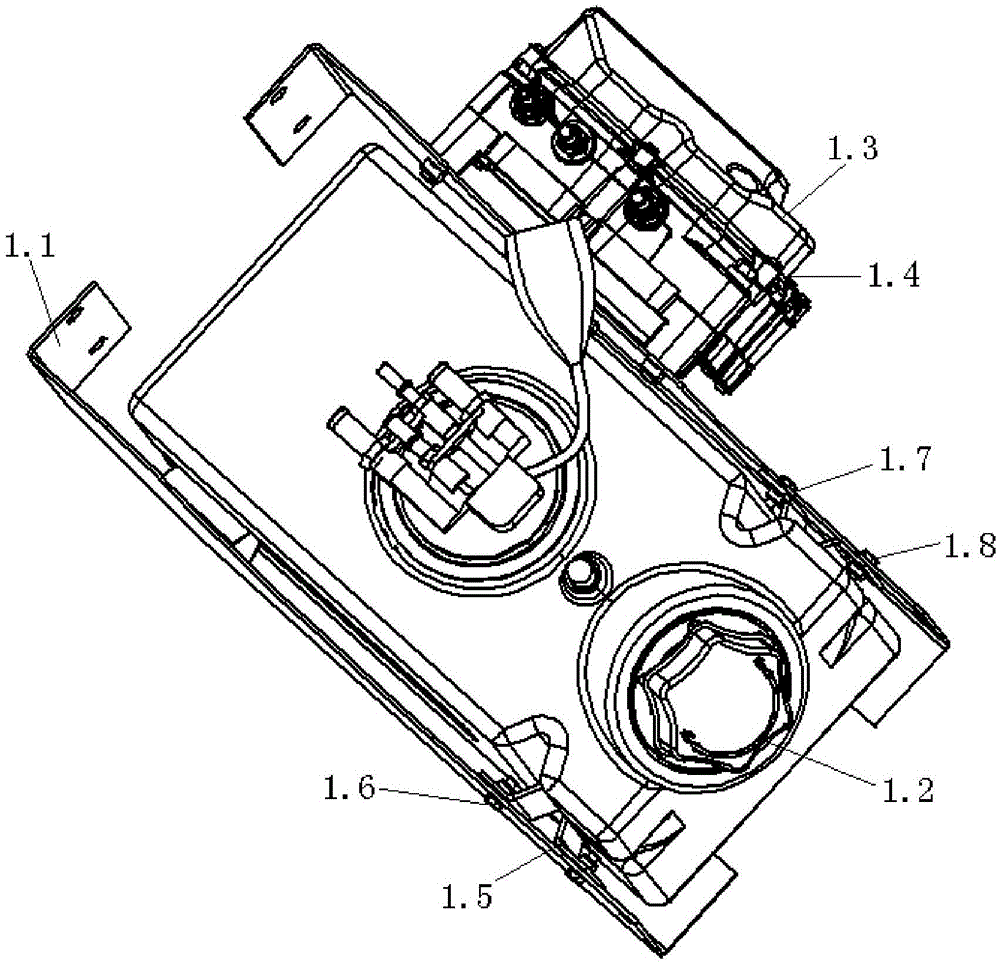

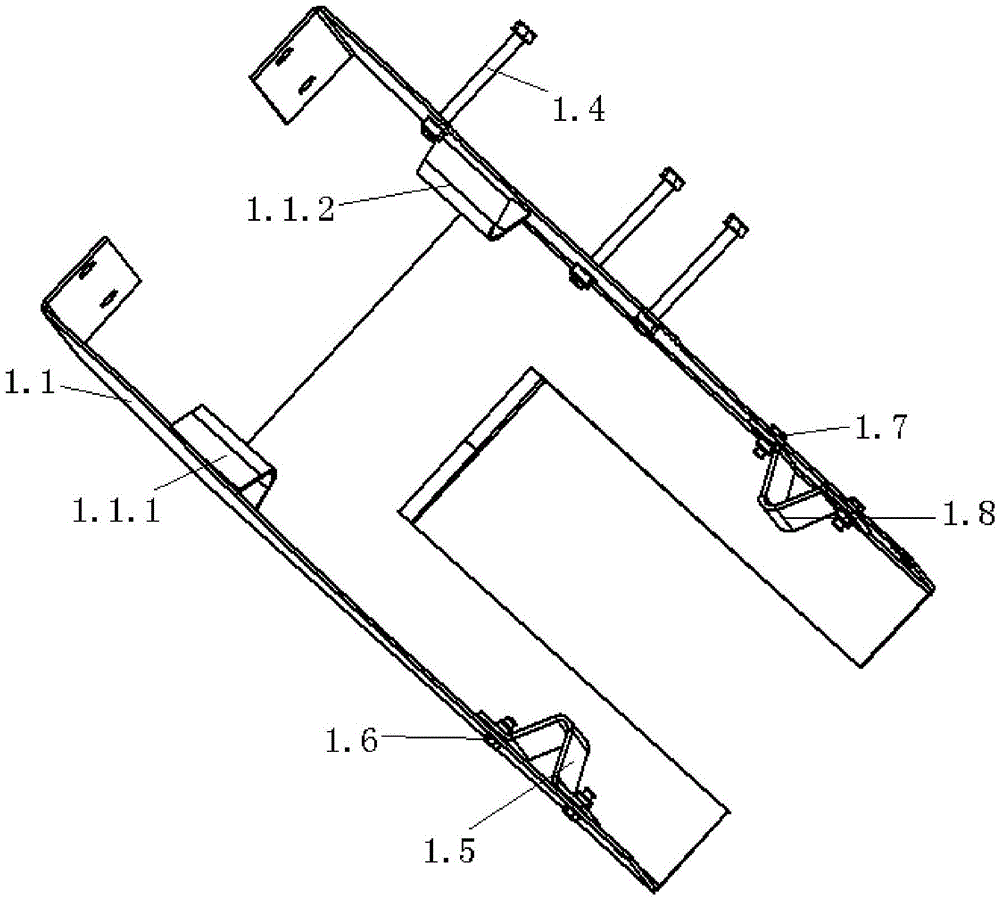

A urea tank bracket

A technology for urea tanks and side baffles, applied in the direction of noise reduction devices, engine components, machines/engines, etc., can solve the problems of urea tank 1.2 interference, poor structural rigidity, and difficult assembly, so as to achieve easy assembly, improve assembly freedom, The effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention are described below through specific examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, and cannot be construed as limitations on the technical solutions of the present invention.

[0034] In this application, the front end refers to the end of the bracket body where the clamp is installed; the outer side refers to the outer side of the outer surface of the two side baffles, and the inner side connected to the bracket body.

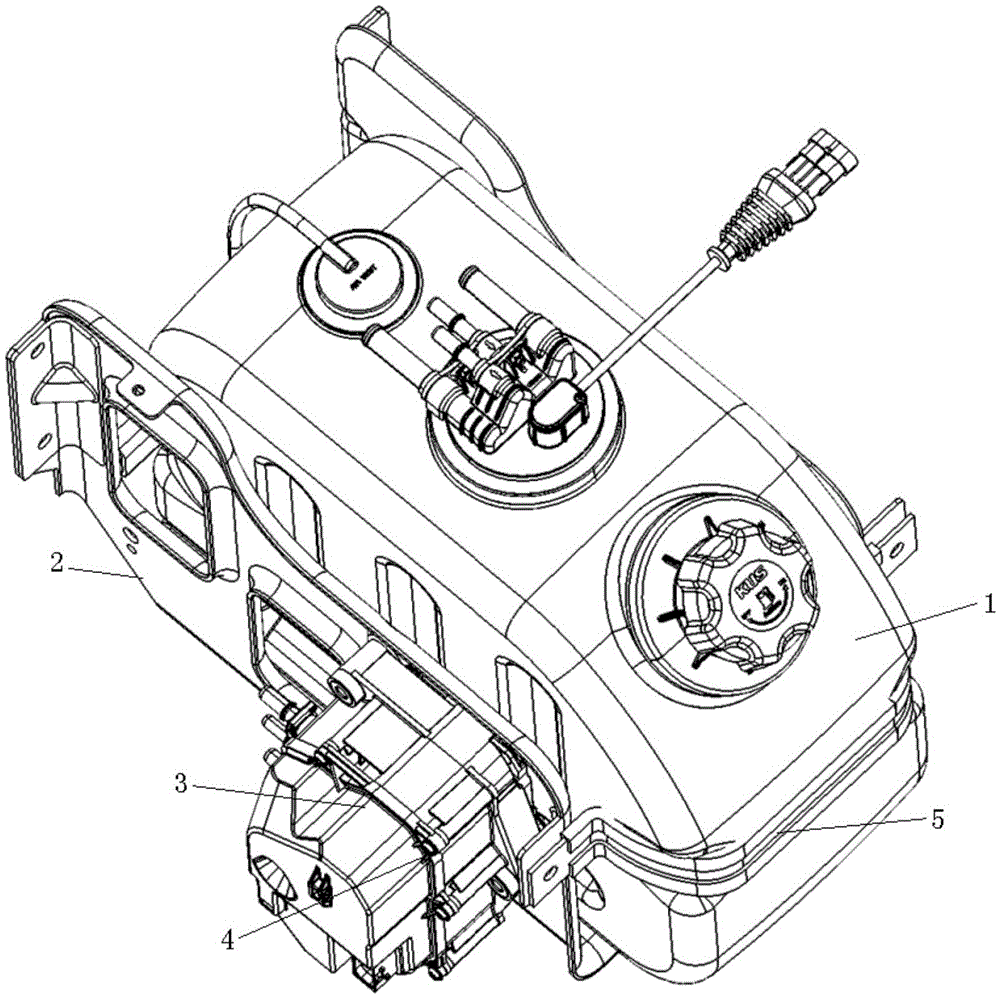

[0035] image 3 It is a schematic diagram of the assembly structure of the urea solution storage system of the present invention. With the upgrading of automobile emission regulations, many vehicles adopt selective catalytic reduction technology to clean exhaust gas. This technology must use a reducing agent, usually urea solution, so the vehicle must have a storage device for the urea solution. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com