High-temperature furnace sealing structure

A sealing structure and high-temperature furnace technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as unsuitable use and wear, and achieve the effect of improving performance and simple and reliable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

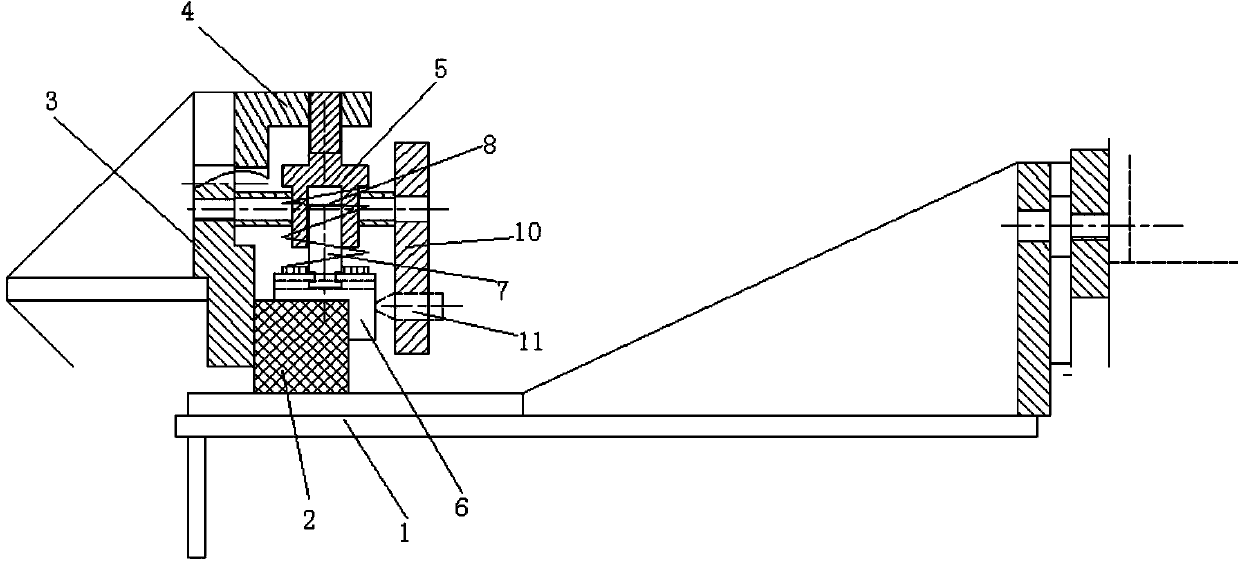

[0009] Referring to the accompanying drawings, the sealing structure of the high temperature furnace includes a supporting surface 1, on which a graphite packing 2 is arranged, the outer end surface of the graphite packing 2 is fitted with a supporting flange 3, and a supporting plate is fixedly installed on the supporting flange 3 4. The upper guide rod 5 is slidably fitted on the support plate 4, the pressure ring 6 is placed on the graphite packing 2, the lower guide rod 7 is fixedly installed on the pressure ring 6, and the upper guide rod 5 is equipped with the lower guide rod 7 to match The guide hole 8 of the upper guide rod 5 is provided with a step outside, and a spring 9 is pressed between the lower end of the step and the pressure ring. The support flange 3 is connected with a fixed plate 10 through a connecting rod, and a top screw 11 is screwed on the fixed plate 10. The pressure is placed inside the pressure ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com