Storage battery

A battery and battery slot technology, applied in battery cover/end cover, battery pack parts, battery box/jacket, etc., can solve the problems of no error proofing, cycle growth of battery production, affecting product quality, etc., to improve product quality. Quality, simplify production process, shorten the effect of production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

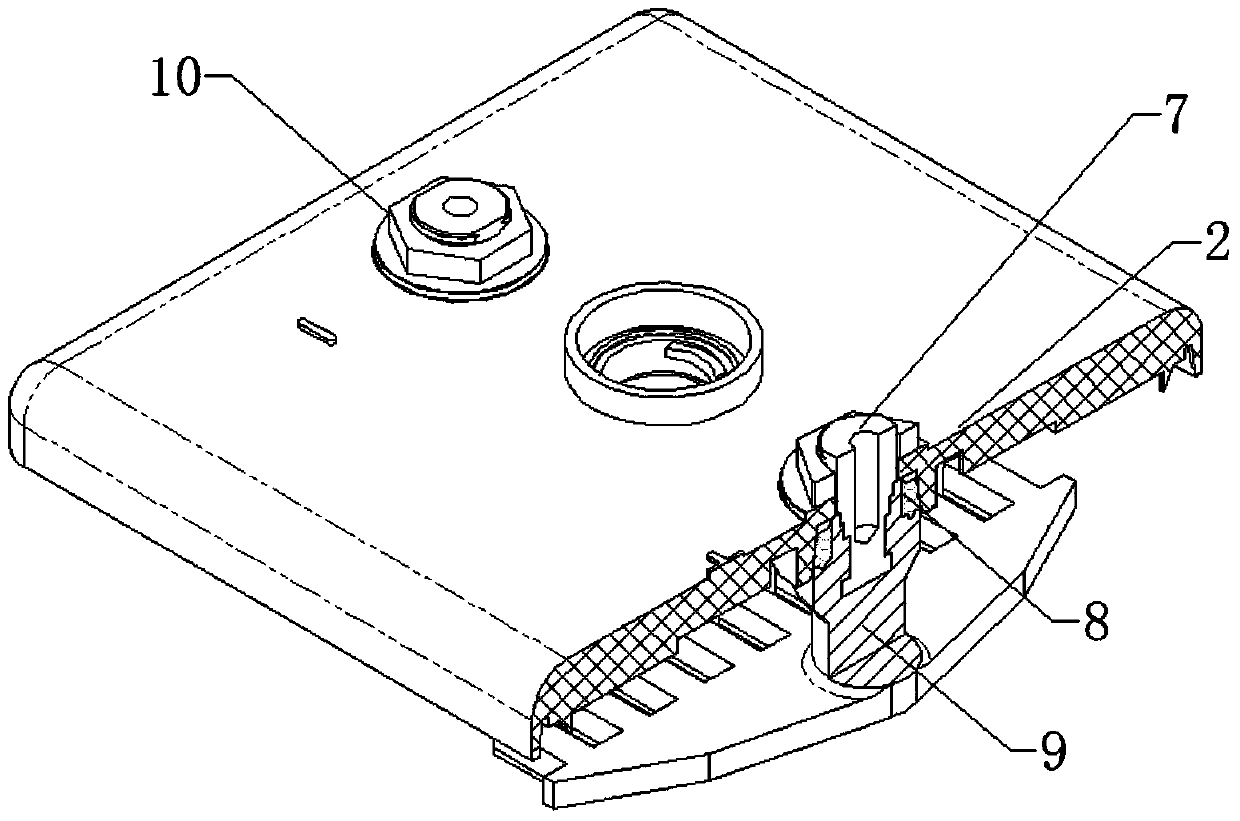

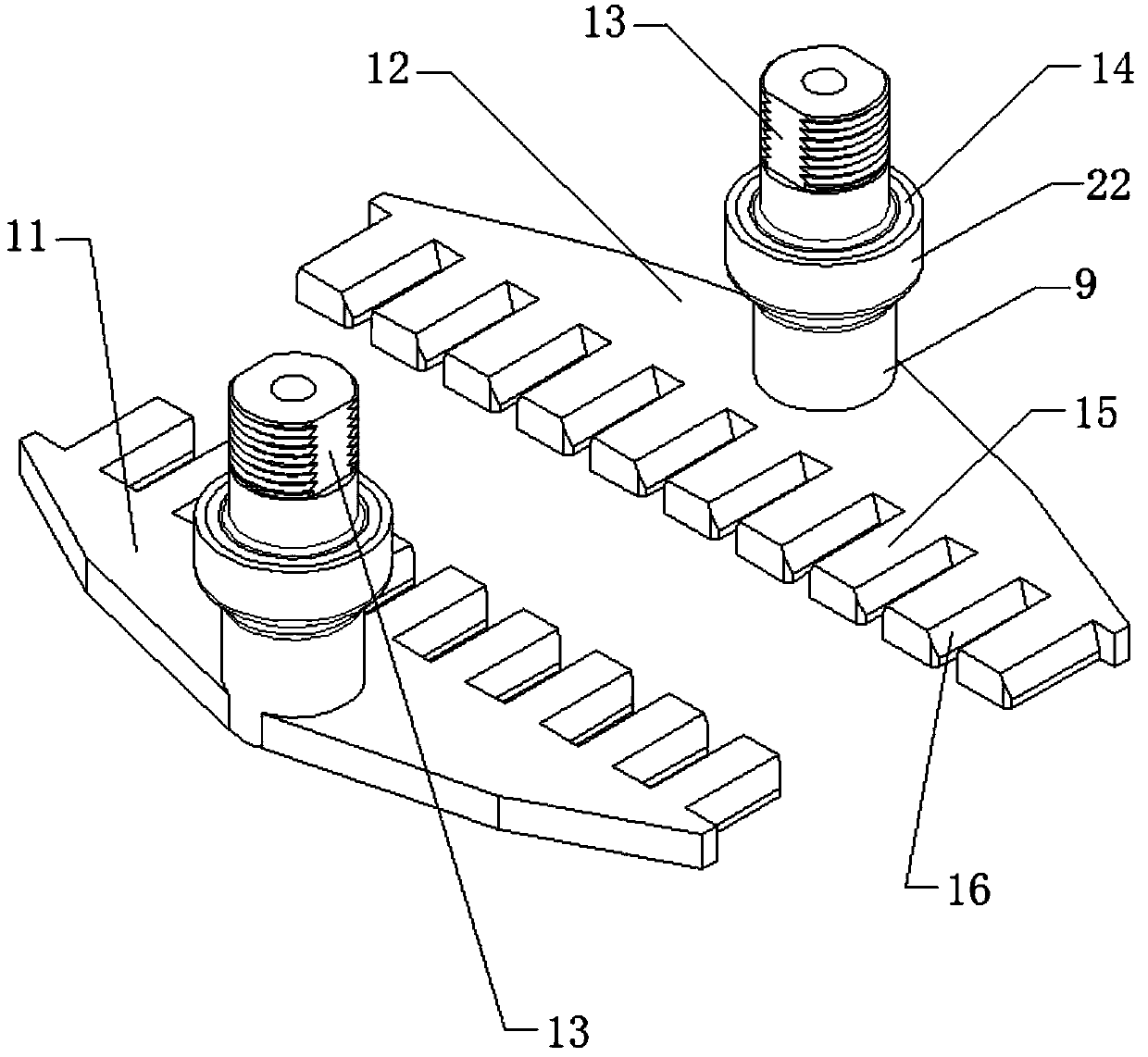

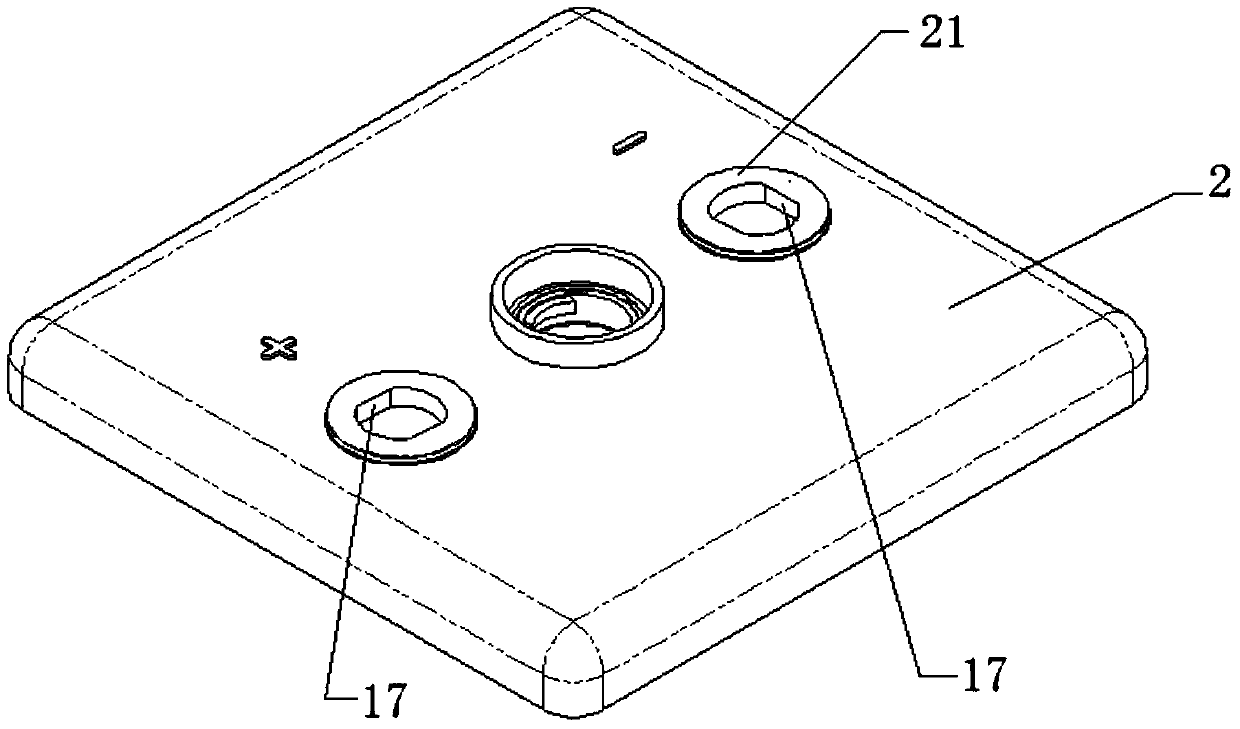

[0020] Referring to the accompanying drawings, a specific structure of the present invention is reflected. The storage battery includes a safety valve 1, a positive terminal 11, a negative terminal 12, a battery cover 2, a battery tank 4, a plate group 5 and an electrolyte 6, and the terminal is composed of a copper insert 7 and a lead body 9. The described The copper insert 7 is embedded in the lead body 9, and the copper insert 7 is made of a round rod. The outer surface of the upper part of the copper insert 7 is provided with a threaded part 23; the middle part of the copper insert 7 is provided with an annular concave-convex part 24; The bottom of the copper insert 7 is provided with an annular boss portion 25; both sides of the threaded portion 23 are symmetrically provided with a cutting portion; the elevation of the cutting portion constitutes the terminal positioning surface 13, and the terminals of the copper insert 7 of the positive and negative terminals The orient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com