Vane-type pump having a housing, having a displaceable stator, and having a rotor that is rotatable within the stator

A vane pump and stator technology, which is applied to liquid fuel engines, pumps, pump components, etc., can solve the problems of large vane pump size and reduced power supply, and achieve the effect of simple rigidity and improved effective power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

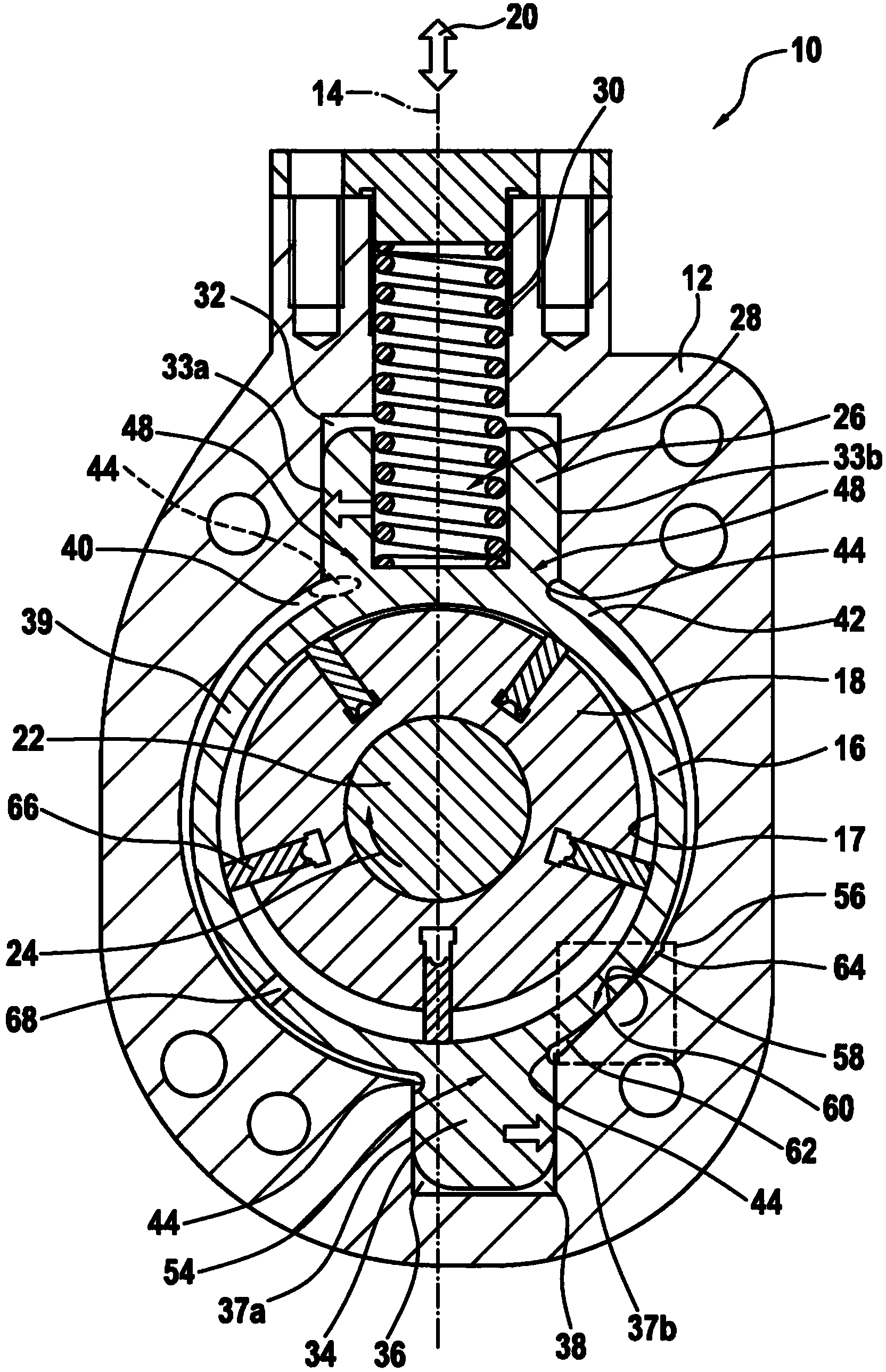

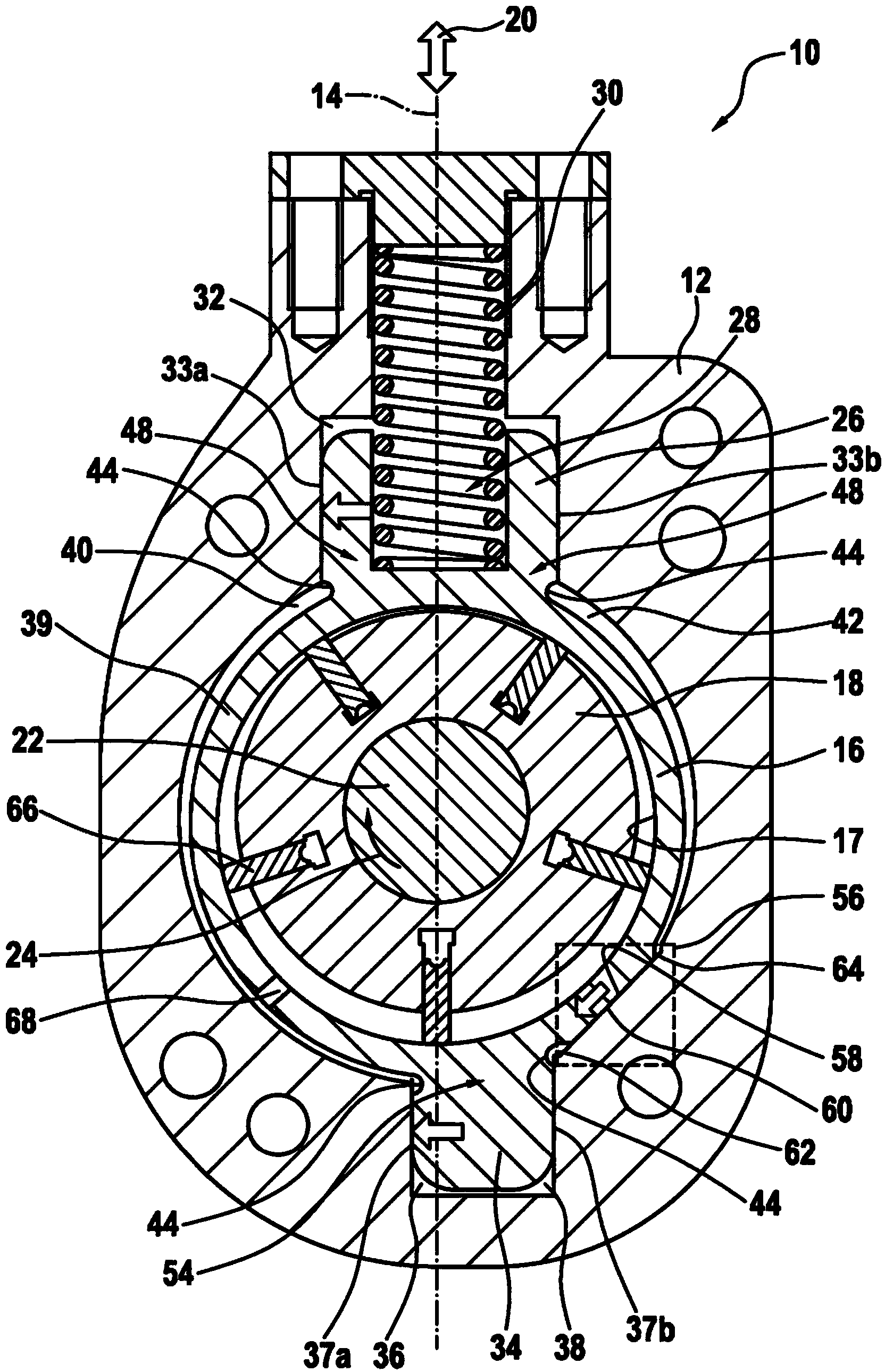

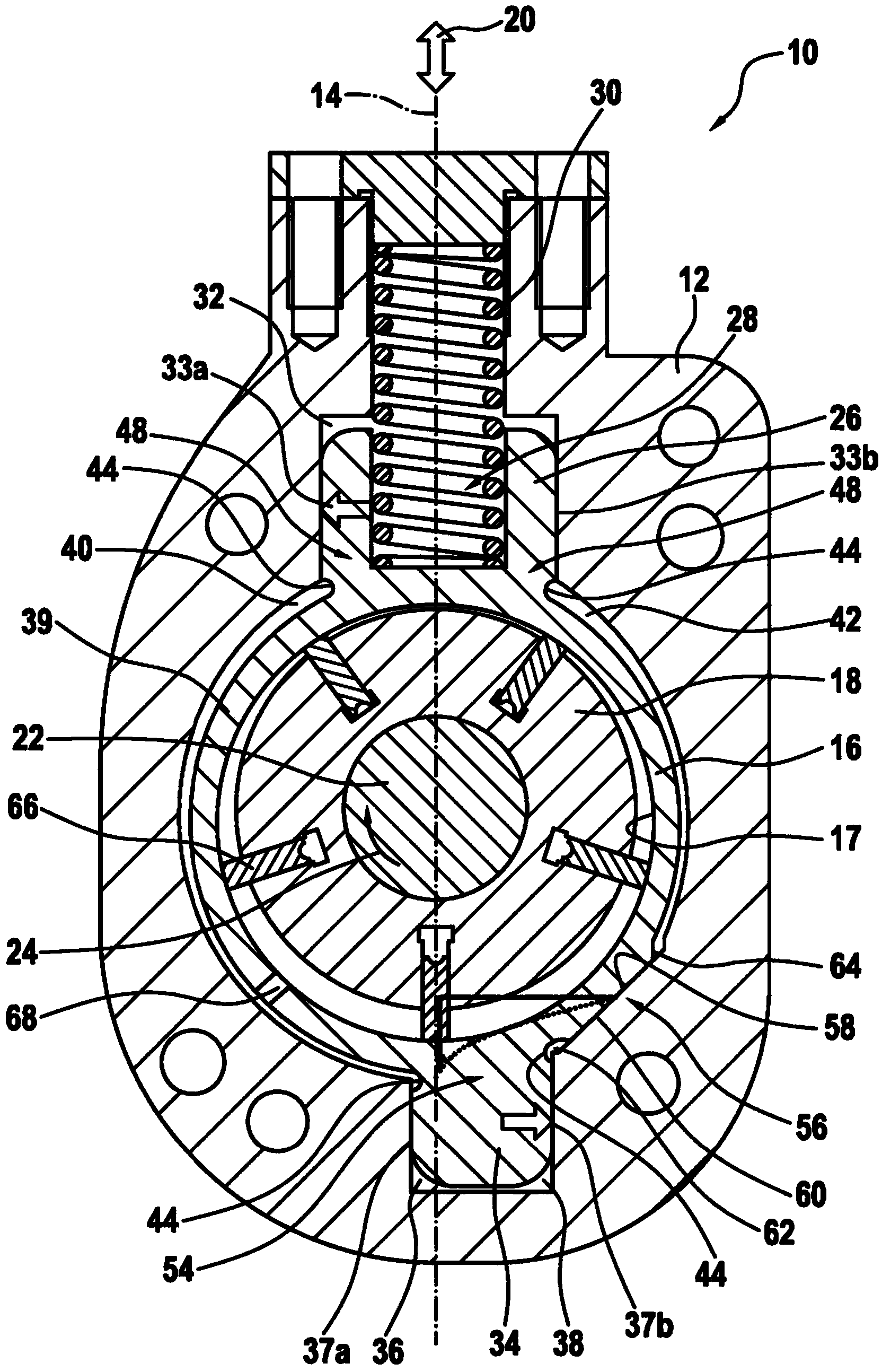

[0017] In all the figures, also in the different embodiments, functionally equivalent elements and dimensions are provided with the same reference numerals.

[0018] figure 1 A sectional view perpendicular to the drive shaft of the first embodiment of the vane pump 10 is shown. The vane pump 10 is, for example, a fuel pump of an internal combustion engine (not shown). The vane pump 10 comprises a housing 12 , a stator 16 movably guided in the housing 12 parallel to the axis 14 , and a rotor 18 accommodated in a recess (wall surface 17 ) of the stator 16 . The direction of movement of the stator 16 in the housing 12 is indicated by a double-headed arrow 20 . The rotor 18 is arranged perpendicular to the drawing on a rotational axis 22 , which is rotatably mounted in the housing 12 in a manner not shown, so that it can be rotated in the clockwise direction corresponding to the arrow 24 . The direction of movement 20 and the axis of rotation 22 are thus perpendicular to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com