Squeezing screw rod for improving grain-sized dicing effect

A juicing snail and pelletizing technology, which is applied in the field of juicing screw, can solve the problems of heavy load on the motor, vibration noise of the juicer, poor squeezing effect, etc., and achieve better juicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

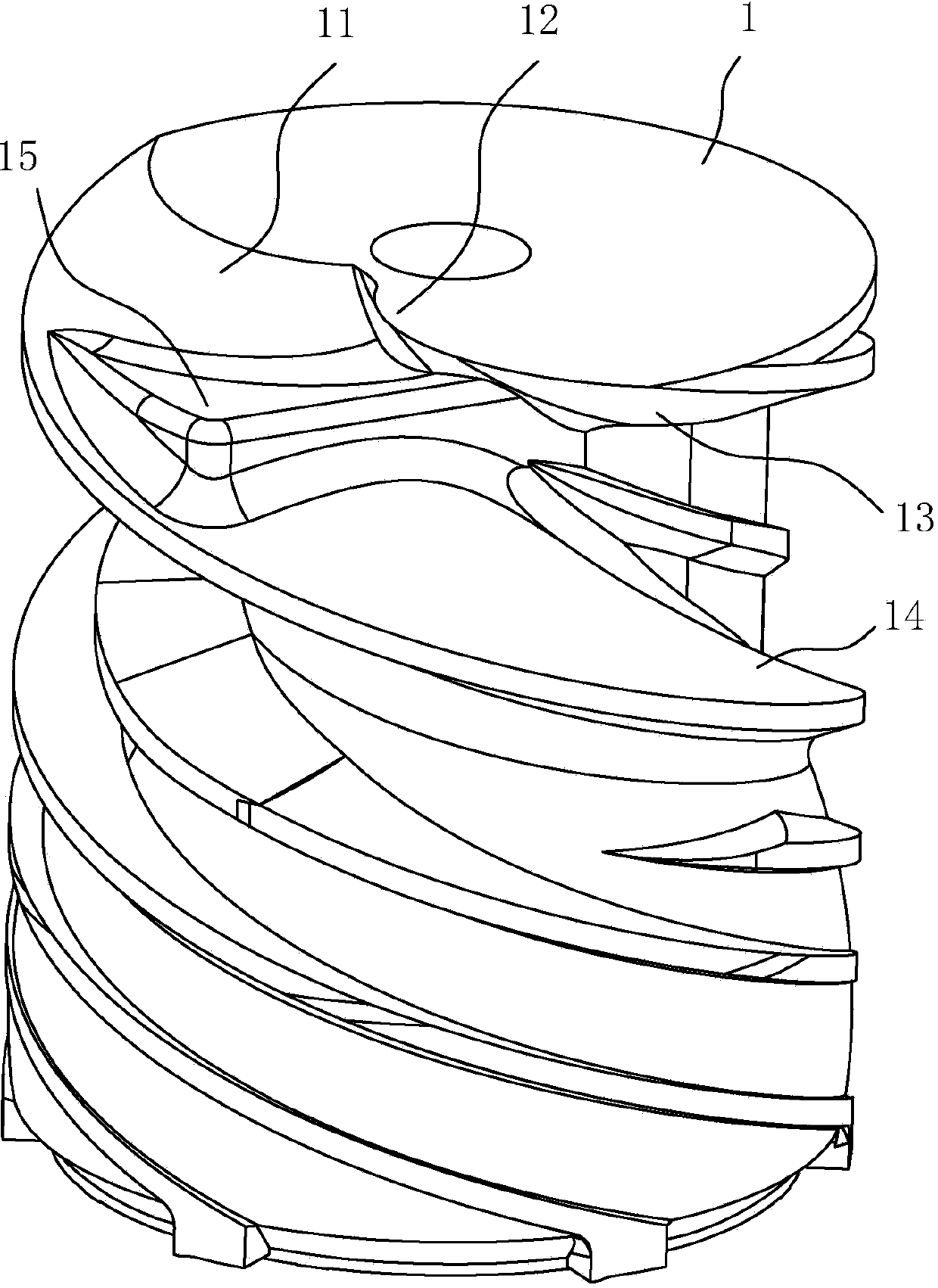

[0008] like figure 1 As shown, a juice extracting screw for improving the cutting effect includes a juice extracting screw 1, the groove wall on the side where the knife edge 12 is formed at the inlet 11 of the juice extracting screw 1 is the upper groove wall 13, and the groove wall on the other side is The lower trough wall 14 , the lower trough wall 13 is formed with a raised material stopper 15 for blocking the material before the knife edge 12 cuts material, and the material stopper 15 is a certain distance away from the knife edge 12 . That is, referring to the rotation direction of the juice extraction screw 1 when the juice extractor is working, the material retaining platform 15 is before the knife edge 12 .

[0009] When squeezing the juice, along with the rotation of the juice squeezing screw 1, when the material is fed from the feed port 11 to the blocking table 15, it will pause to continue feeding, and then the material will be cut off by the knife edge 12. Sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com