Juicing device for food processing

A technology for food processing and juicing, which is applied in the fields of juicing devices and juicing devices for food processing, can solve the problems of inconvenient extrusion, large initial volume of fruits, increased processing costs, etc., so as to save costs and reduce waste of juice resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

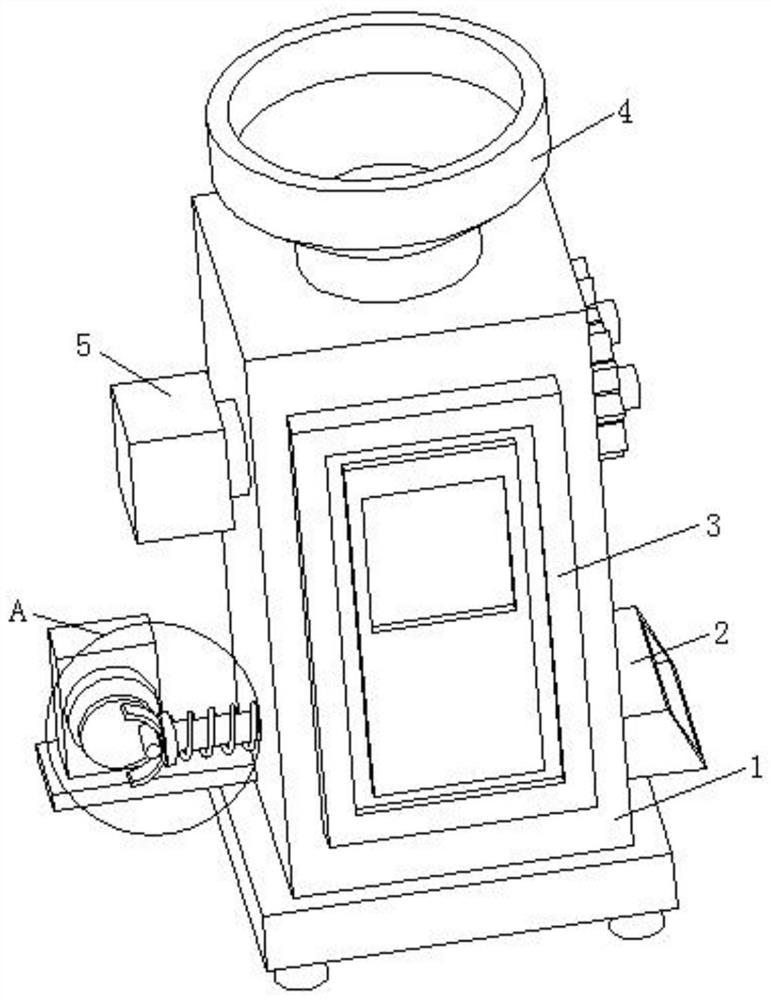

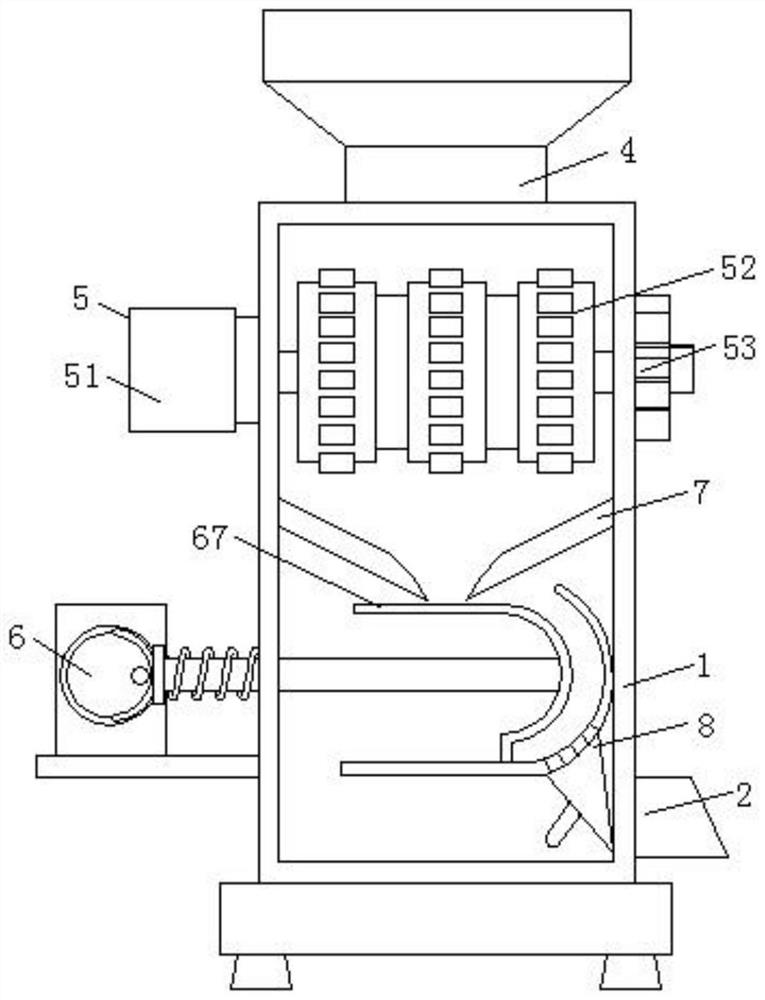

[0031] Such as Figure 1-8 As shown, the present invention provides a juicer for food processing, comprising a body 1, the top surface of the body 1 is fixedly connected with a feed port 4, the bottom end of the right side of the body 1 is fixedly connected with a discharge port 2, the body 1 The front of the body 1 is movably connected with a box door 3, and the box door 3 is set to facilitate the opening of the body 1, so as to facilitate the collection of fruits after squeezing the juice in the body 1. The top left side of the body 1 is fixedly connected with a crushing mechanism 5, and the crushing mechanism 5 Including the first motor 51, the model of the first motor 51 is MS-0.37kw-4, the output shaft of the first motor 51 extends to the inside of the body 1 and is fixedly connected with the extrusion cylinder 52, and the bottom end on the left side of the body 1 is fixedly connected There is an extruding mechanism 6, which includes a second motor 61, the model of which ...

Embodiment 2

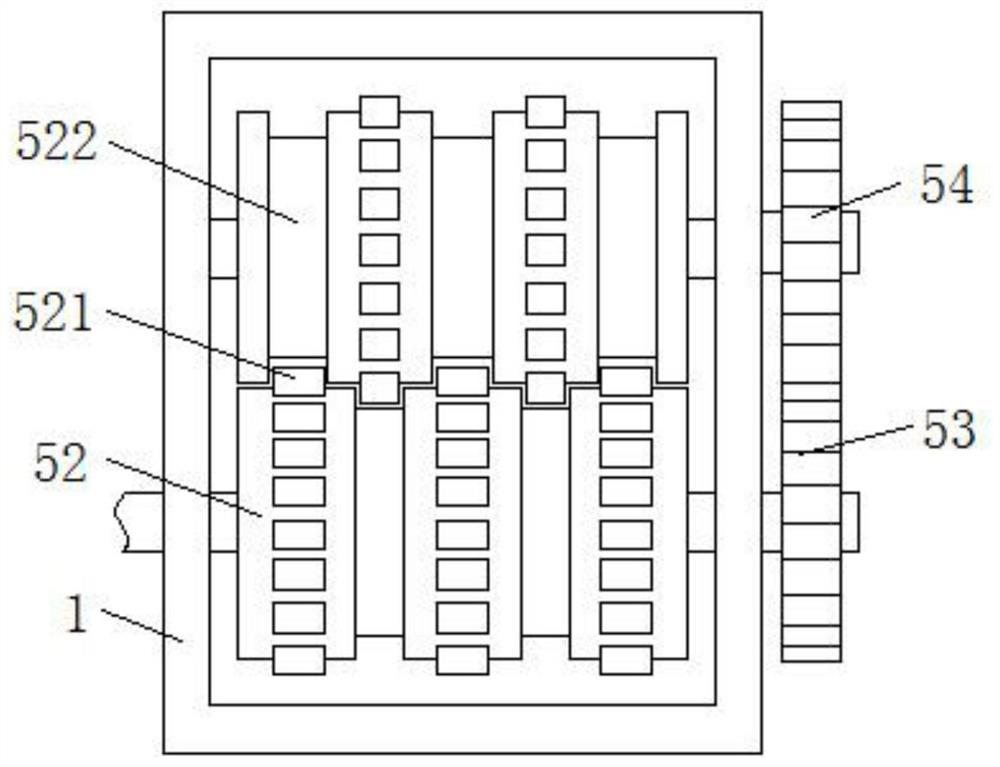

[0034] Such as Figure 1-8As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a buffer groove 522 is opened on the extrusion cylinder 52, and the extrusion cylinder 52 includes a buffer mechanism 521, and the buffer mechanism 521 and the buffer groove 522 correspond to each other. Adaptation, the buffer mechanism 521 includes a buffer piece 5211, the bottom surface of the buffer piece 5211 is fixedly connected with a straight rod 5212, the extrusion cylinder 52 is provided with a rod groove 5214, one end of the straight rod 5212 extends into the rod groove 5214, and the bottom surface of the buffer piece 5211 The bottom surface is fixedly connected with an extruding spring 5213, and one end of the extruding spring 5213 is fixedly connected on the extruding cylinder 52, and adopts the cooperation of the buffer sheet 5211, the buffer groove 522, the extruding spring 5213, and the straight rod 5212, and the buffer sheet 5211 is ...

Embodiment 3

[0036] Such as Figure 1-8 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the buffer sheet 5211 includes a plate 52111, the bottom of the inner cavity of the plate 52111 is fixedly connected with a rubber layer 52115, and the top surface of the rubber layer 52115 A waterproof layer 52114 is fixedly connected, and the material of the waterproof layer 52114 is polyurethane waterproof material. The top surface of the waterproof layer 52114 is fixedly connected with an iron layer 52113, and the top surface of the plate 52111 is fixedly connected with a fin 52112. The middle part of the inner cavity of the fin 52112 A rotating shaft 521122 is fixedly connected, and a crushing blade 521123 is movably connected to the rotating shaft 521122. One end of the crushing blade 521123 extends to the outside of the fin 52112 and is fixedly connected with a crushing tooth 521124. The right side of the bottom end of the crushing blade 521123...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com