Rotary liquid feeding type plasma operation electrode

A plasma and surgical electrode technology, applied in the direction of heating surgical instruments, etc., can solve the problems of affecting the solution delivery effect and flushing effect, affecting the stability and efficiency of the operation, and the liquid is not smooth, so as to achieve processing difficulty and low manufacturing cost , The effect of continuous liquid supply and concentrated solution jet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

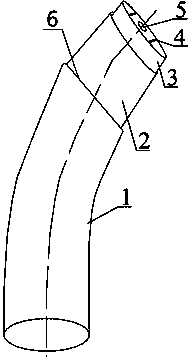

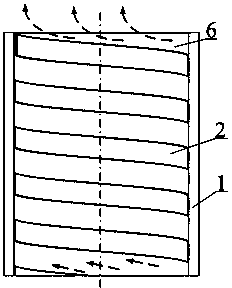

[0019] A plasma surgical electrode with rotating liquid supply mode, such as figure 1 As shown, it includes sheath, tubular outer electrode, inner electrode base, inner electrode, drainage port and water injection port. Sheath 1 is an insulating sleeve, which can be made of insulating and high temperature resistant materials such as PVC, PE or PTFE. The inner surface of the sleeve has a spiral groove, the tubular outer electrode 2 is a stainless steel tube, the sheath 1 is tightly wrapped on the outer surface of the tubular outer electrode 2, and a spiral liquid supply tank is formed between the sheath and the tubular outer electrode, as figure 2 As shown; the end of the tubular outer electrode is not covered by the sheath, and the inner electrode base is embedded in the end of the tubular outer electrode. The inner electrode base 3 can be made of high-temperature-resistant plastic PTFE, PEEK, PI or ceramics, and a drainage port 5 is processed on it. and a structure capable o...

Embodiment 2

[0021] A plasma surgical electrode with rotating liquid supply mode, such as figure 1 As shown, it includes a sheath, a tubular outer electrode, an inner electrode base, an inner electrode, a drainage port and a water injection port, the sheath 1 is an insulating sleeve, and the material can be PVC, PE or PTFE, etc. The outer electrode 2 is a stainless steel tube , a spiral groove is processed on the outer surface of the tubular outer electrode, the sheath 1 is tightly wrapped on the outer surface of the tubular outer electrode 2, and a spiral liquid supply groove is formed between the sheath and the tubular outer electrode, as figure 2 As shown; the end of the tubular outer electrode is not covered by the sheath, and the inner electrode base is embedded in the end of the tubular outer electrode. The inner electrode base 3 can be made of high-temperature-resistant plastic PTFE, PEEK, PI or ceramics, and a drainage port 5 is processed on it. and a structure capable of fixing t...

Embodiment 3

[0023] A plasma surgical electrode with rotating liquid supply mode, such as figure 1 As shown, including the sheath, tubular outer electrode, inner electrode base, inner electrode, drainage port and water injection port, the sheath 1 is an insulating sleeve, and the material can be PVC, PE or PTFE, etc., and the tubular outer electrode 2 is stainless steel Tube, the filament is spirally wound on the tubular outer electrode, the sheath 1 is tightly wrapped on the outer surface of the tubular outer electrode 2, and a spiral liquid supply tank is formed between the sheath and the tubular outer electrode, such as figure 2 As shown; the end of the tubular outer electrode is not covered by the sheath, and the inner electrode base is embedded in the end of the tubular outer electrode. The inner electrode base 3 can be made of high-temperature-resistant plastic PTFE, PEEK, PI or ceramics, and a drainage port 5 is processed on it. and a structure capable of fixing the internal electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com