Comprehensive sand-gravel barrier

A kind of sand and gravel barrier, comprehensive technology, applied in the direction of upper structure, deflector, upper structure sub-assembly, etc., can solve the problems of narrow protection range and single structure of the shielding plate, so as to enhance the protection performance, reduce the entry of sand and dust, The effect of extending the scope of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

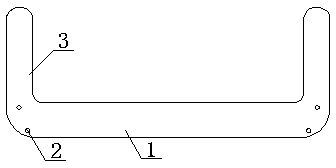

[0009] Such as figure 1 It is a schematic diagram of the structure of the present invention, a comprehensive sand and gravel baffle, including a baffle plate 1 and an installation hole 2, the installation holes are arranged at both ends of the baffle plate 1, and the two ends of the baffle plate 1 are provided with wing plates 3, and the wing plate 3 rises and forms a "U" shape structure with the baffle plate 1.

[0010] The two ends of the baffle plate 1 are provided with rising fenders 3, which are combined with the baffle plate 1 to form a "U"-shaped structure, which can not only protect the front paint surface of the hood, but also protect the side paint surface of the hood and the engine. The gap between the cover and the engine compartment reduces the entry of sand and dust, expands the protection range, and enhances the protection performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com