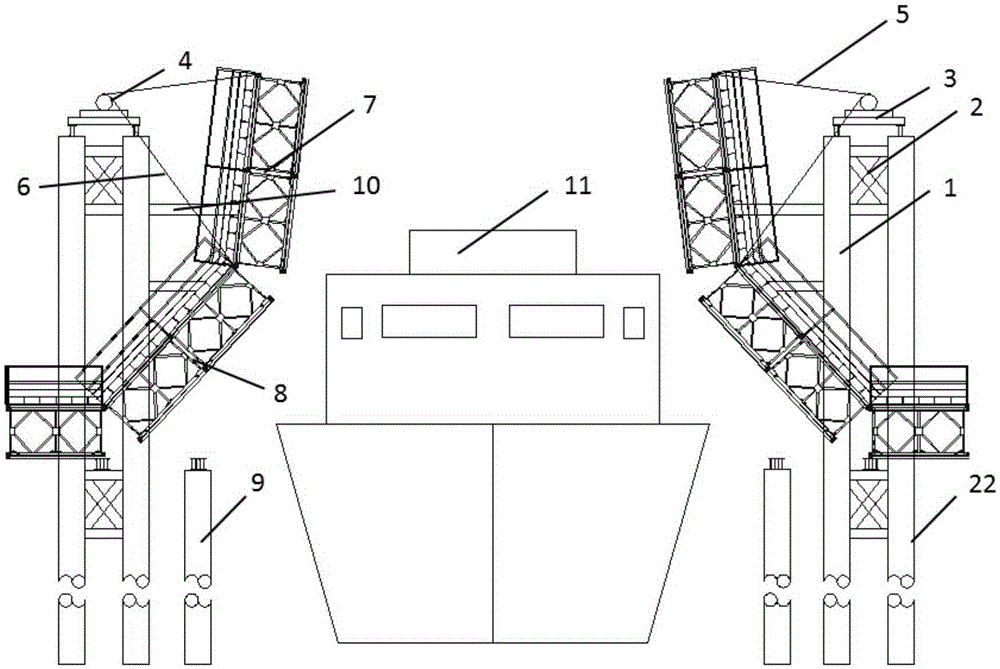

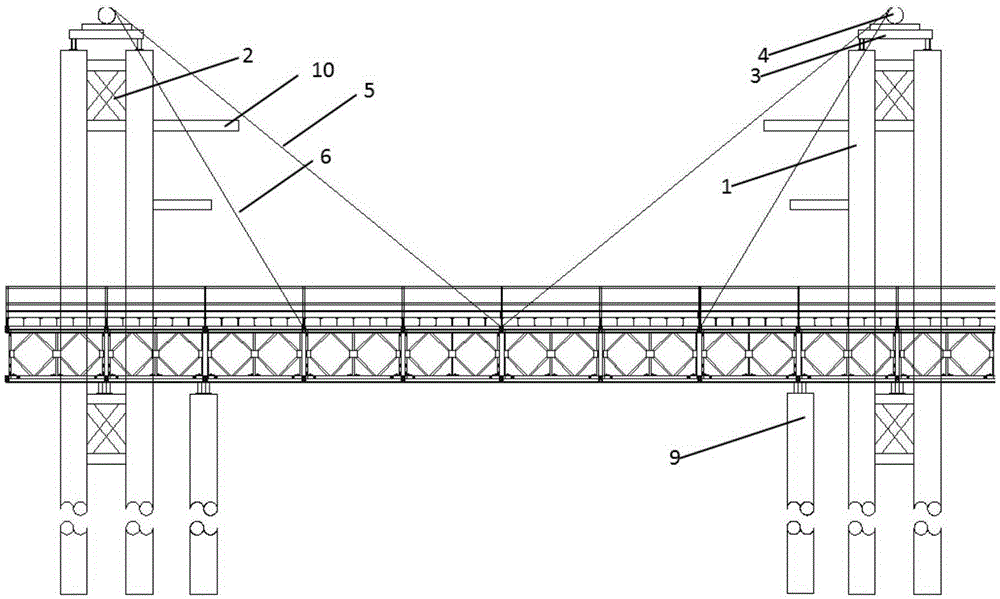

Construction method of a cable-stayed bendable trestle structure

A construction method, cable-stayed technology, applied to the structure and construction field of trestle bridges in bridge construction, can solve problems such as unfavorable construction machinery, material turnover, construction impact on both sides of the bridge, and excessive navigation clearance, etc., to achieve the elimination of navigation clearance restrictions , Accurate control of opening precision, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

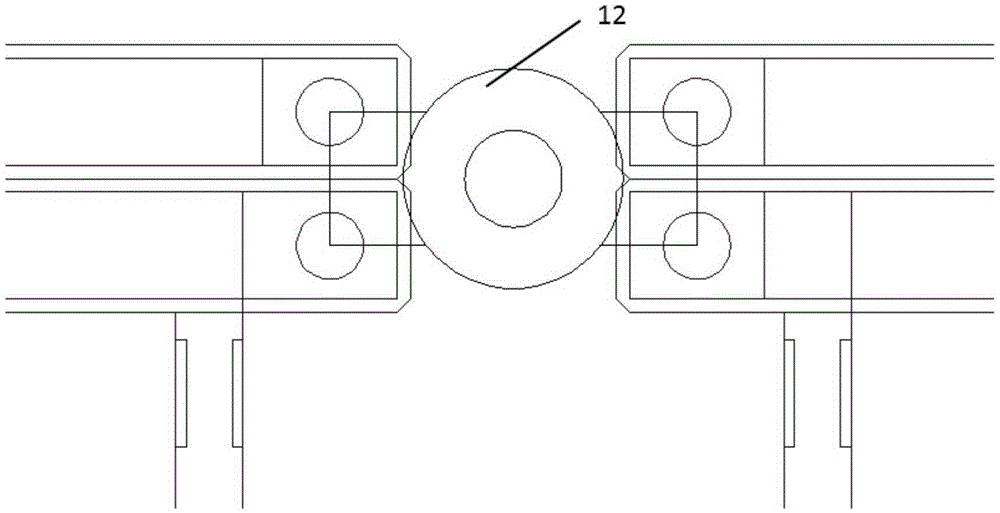

[0041] (1) Set two sets of lattice columns on each side of the set bridge deck position, each set of lattice columns is composed of 4 steel pipes, and the 4 steel pipes of each set of lattice columns 1 are welded and fixedly connected. Preferably, the 4 steel pipes of each group of lattice columns 1 are fixedly welded and connected by diagonal braces and cross braces 2 to form a scissors brace, and then a distribution base 3 is installed on the top of each lattice column, and then each distribution base 3 Four winches 4 are installed on the top and the upper and lower limit beams 10 are respectively welded up and down on the inner side of each lattice column;

[0042] (2) Insert and drive fixed support piles 9 to the set elevation respectively along the bridge direction on the inner sides of the lattice columns 1 on both sides;

[0043] (3) Insert bent pier pipe piles 24 between the two groups of lattice columns 1 on the same side to the set elevation, and then weld and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com