Automatic paper wrapping machine

A paper wrapping machine, automatic technology, applied to electrical components, circuits, conductor/cable insulation, etc., can solve the problems of increased traction difficulty, inconvenient wrapping operation, roll paper breaking, etc., to achieve wrapping tightness and uniform thickness , Avoid unstable output, improve the effect of easy paper breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the technical solution of the present invention, the automatic wrapping machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

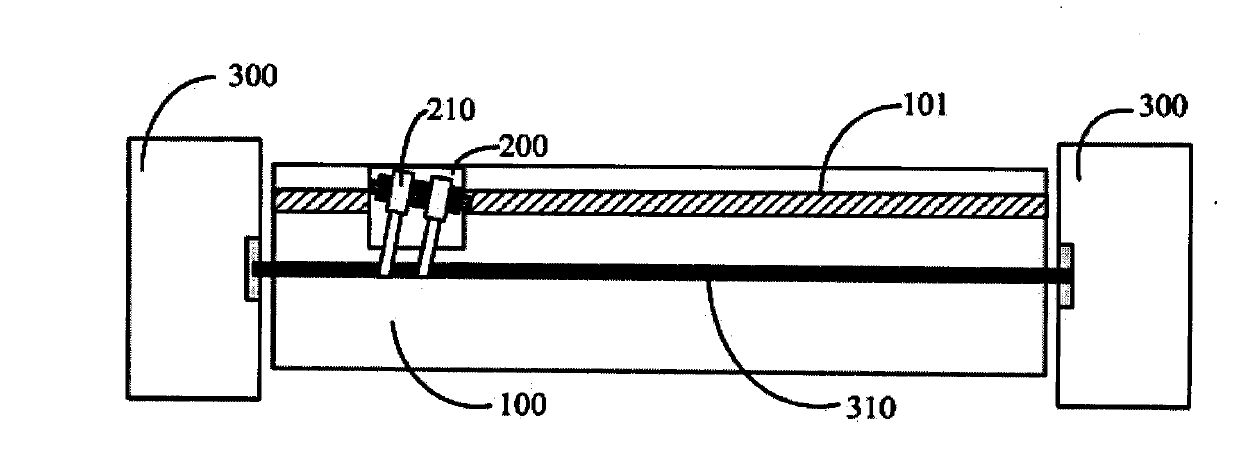

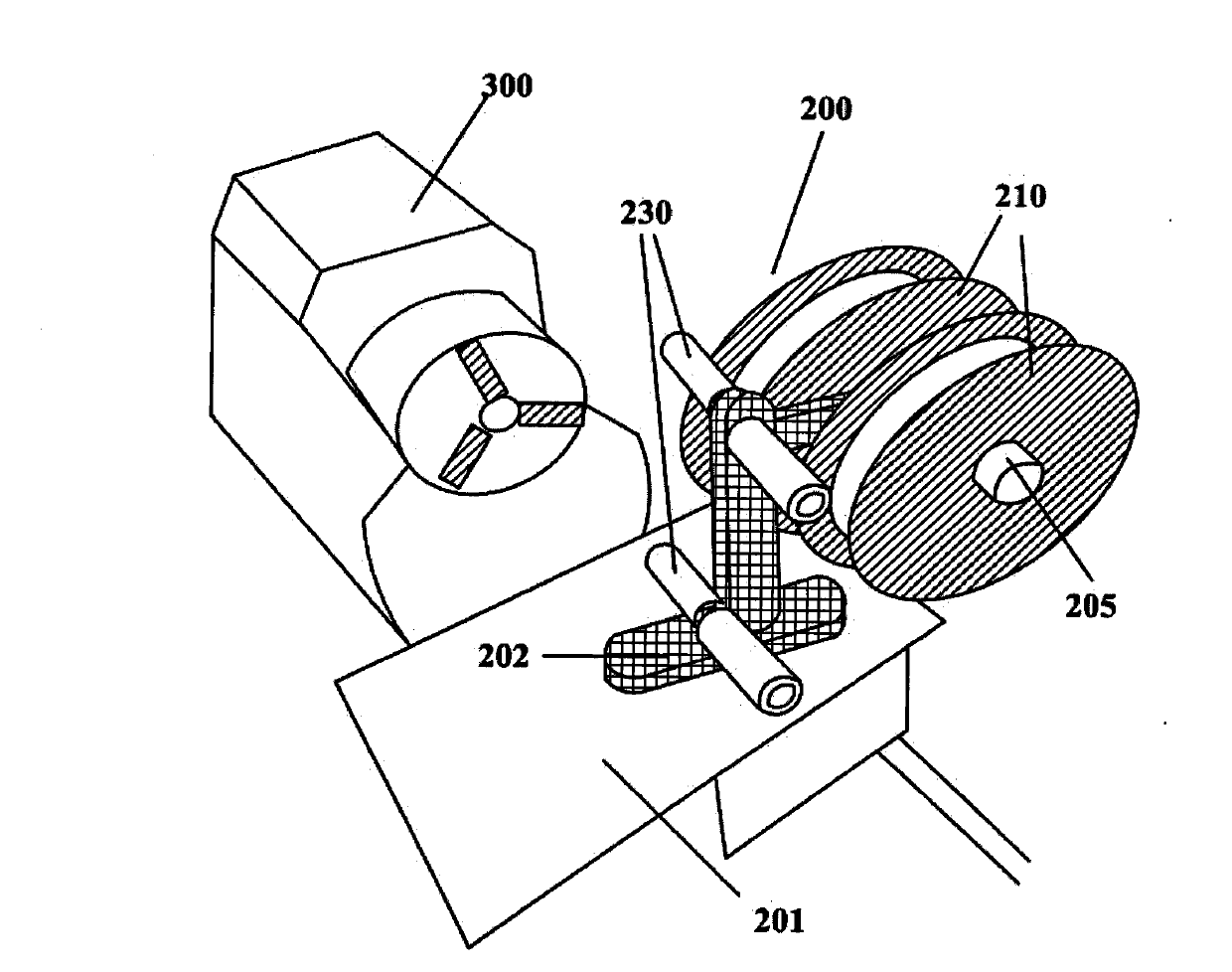

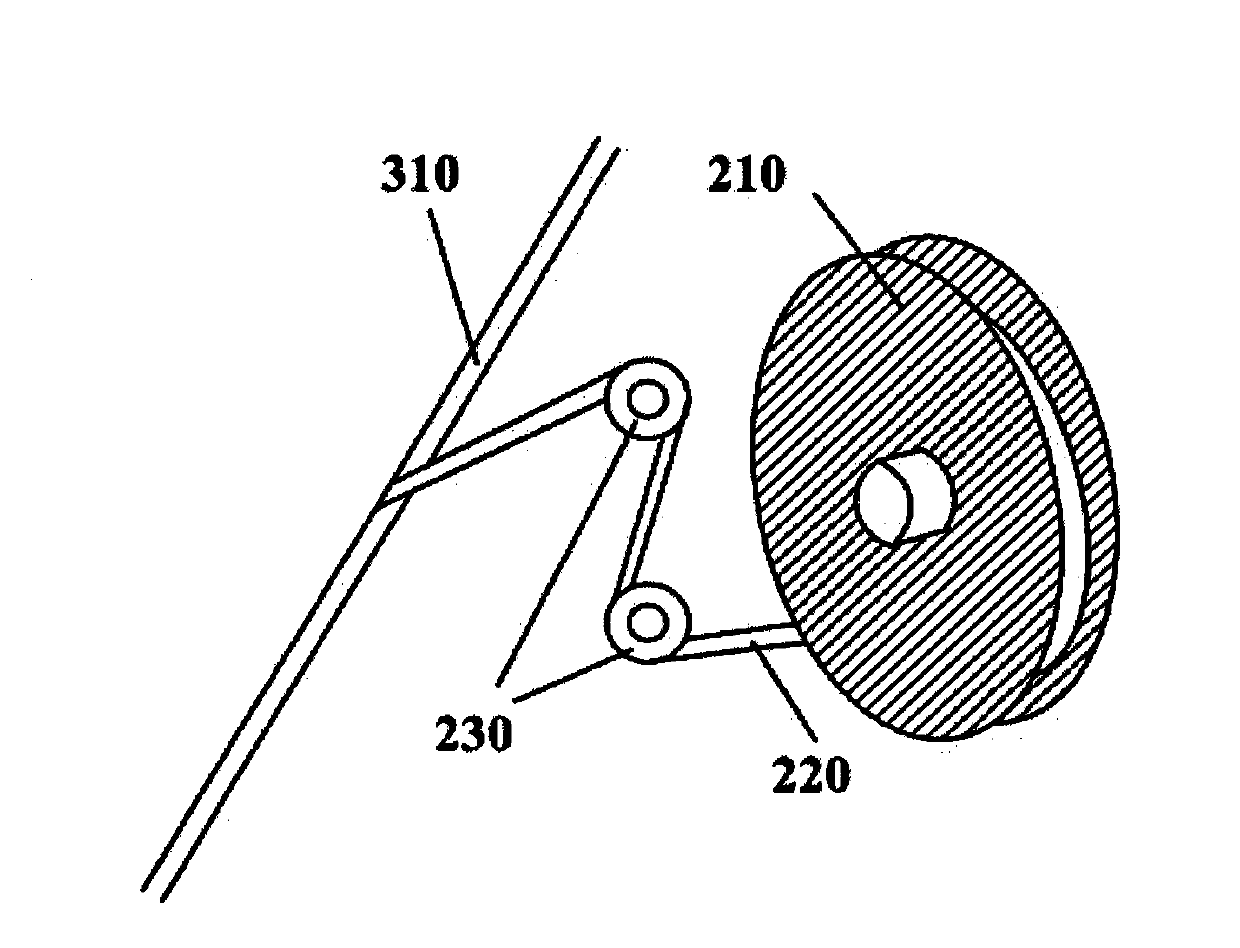

[0043] see figure 1 , which shows a schematic structural view of an automatic wrapping machine provided by an embodiment of the present invention. like figure 1 As shown, the automatic wrapping machine includes a platform 100 , a feeding trolley 200 , and a first movement mechanism 300 . Wherein, the first movement mechanism 300 is used to drive the processing line 310 to rotate; the platform 100 is provided with a slide rail 101, and the slide rail 101 is arranged parallel to the direction in which the processing line extends, and the discharging trolley 200 can Move back and forth along the slide rail 101; the discharge trolley 200 is provided with a material roll 210, and one end of the paper wound on the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com