Film winding and loading integrated robot for logistics trays and using method of film winding and loading integrated robot

An all-in-one, robotic technology, applied in chemical instruments and methods, cleaning methods using gas flow, packaging machines, etc., can solve problems such as material ejection, and achieve the effect of avoiding injury, convenient movement, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

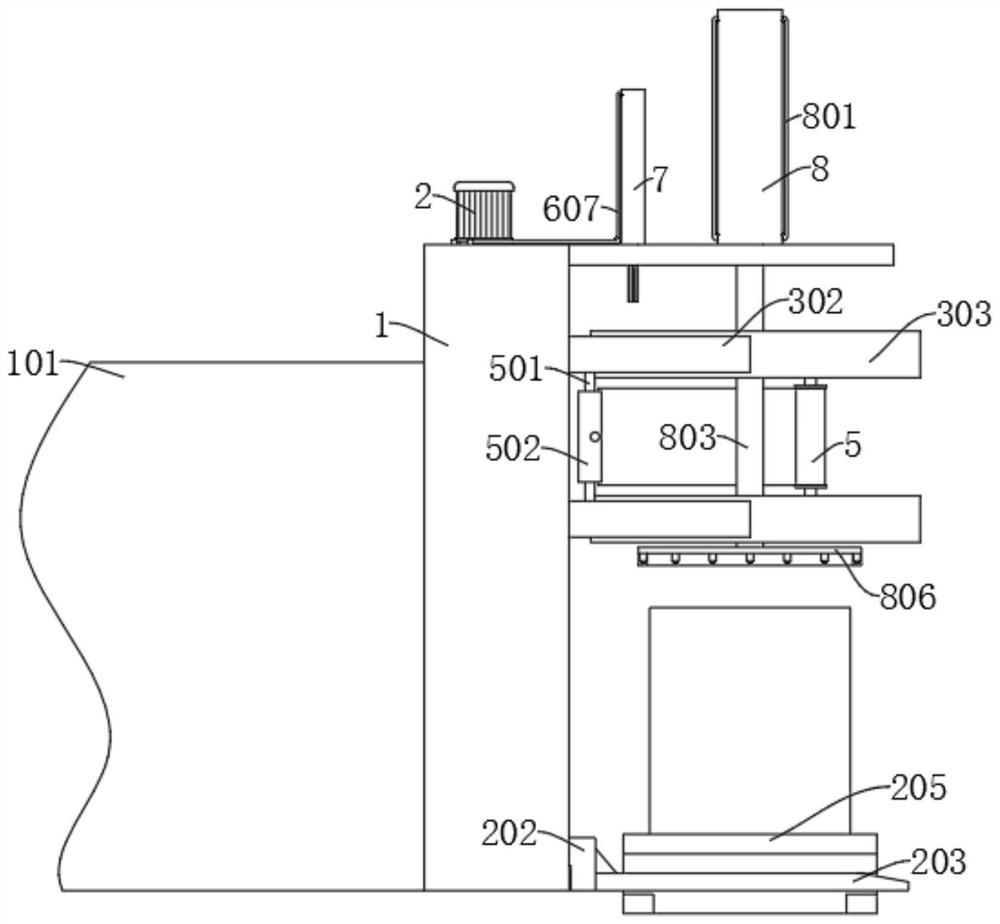

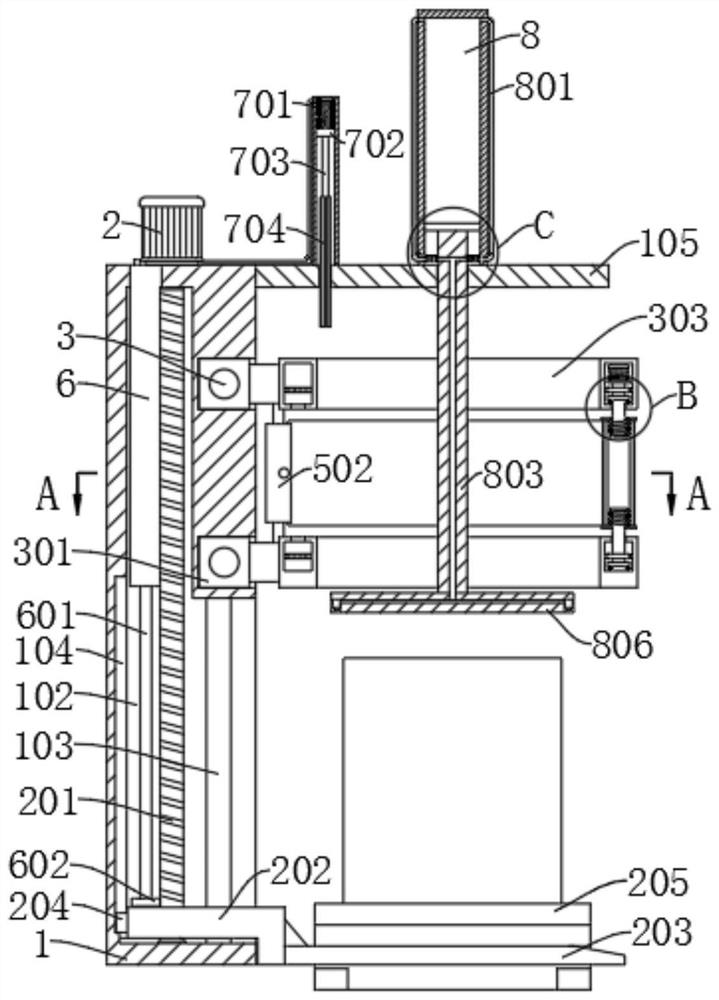

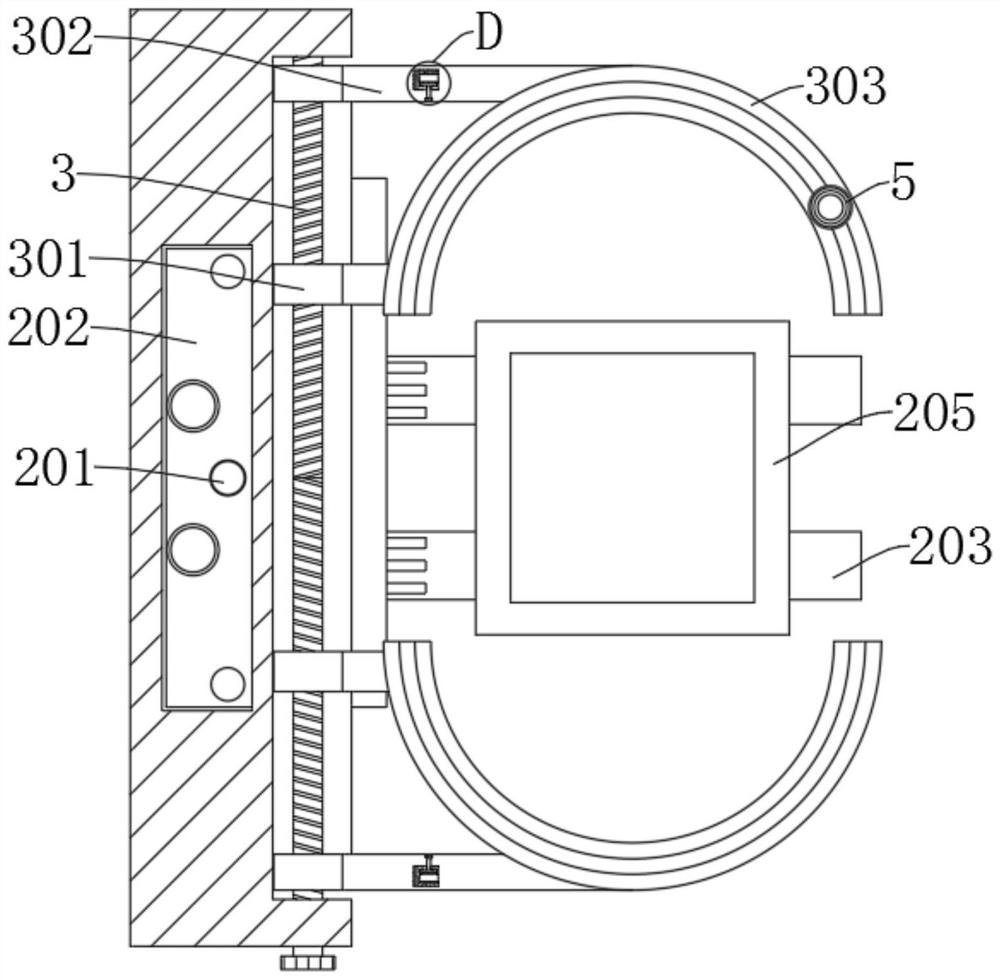

[0041] refer to Figure 1-4 , Image 6 with Figure 7 , an integrated logistics pallet wrapping and loading robot, including a fixed block 1 and a mobile device 101, the fixed block 1 is fixedly connected with the mobile device 101, a cavity 102 is provided in the fixed block 1, and a support is slidably connected in the cavity 102 Plate 202, the support plate 202 is fixedly connected with the inserting plate 203, the inserting plate 203 cooperates with the logistics tray 205, the inserting plate 203 can insert the logistics tray 205, so that the material rises; the fixed block 1 is slidably connected with two semicircular Ring block 303, two semicircular ring blocks 303 are provided with chute 304, both chute 304 are provided with rotating shaft 401, and the end of rotating shaft 401 placed outside chute 304 is provided with first baffle plate 406 , the first baffle plate 406 is connected with the second baffle plate 408 through the first spring 407, the second baffle plate...

Embodiment 2

[0044] refer to figure 1 with figure 2 , an integrated logistics pallet 205 wrapping and loading robot, including a fixed block 1 and a mobile device 101, the fixed block 1 is fixedly connected to the mobile device 101, a cavity 102 is provided in the fixed block 1, and a cavity 102 is slidably connected with The supporting plate 202 is fixedly connected with the inserting plate 203, and the inserting plate 203 cooperates with the logistics tray 205, and the inserting plate 203 can insert the tray 205, so that the material rises; the fixed block 1 is slidably connected with two semicircles Ring block 303, two semicircular ring blocks 303 are provided with chute 304, both chute 304 are provided with rotating shaft 401, and the end of rotating shaft 401 placed outside chute 304 is provided with first baffle plate 406 , the first baffle plate 406 is connected with the second baffle plate 408 through the first spring 407, the second baffle plate 408 is slidably connected to the ...

Embodiment 3

[0048] refer to Figure 1-4 with Figure 8 , an integrated logistics pallet wrapping and loading robot, including a fixed block 1 and a mobile device 101, the fixed block 1 is fixedly connected with the mobile device 101, a cavity 102 is provided in the fixed block 1, and a support is slidably connected in the cavity 102 plate 202, the support plate 202 is fixedly connected with a flashboard 203, the flashboard 203 is matched with the logistics tray 205, the flashboard 203 can insert the logistics tray 205, so that the material rises; the chute 304 is provided with a second motor 4, The output end of the second motor 4 is provided with a rotating shaft 401, and the outer wall of the rotating shaft 401 is fixedly connected with a gear 402, and the inner walls of the two semicircular ring blocks 303 are all provided with an annular rack 305 meshed with the gear 402, and the rotating shaft 401 The outer wall of the outer wall is also rotatably connected with a bearing block 403,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com