Cage system for self-bred cages

A self-crossing cage and skeleton technology, applied in the field of cage system, can solve the problems such as the inability to balance ventilation and thermal insulation of self-crossing cages, insufficient elasticity of the bottom net, etc., so as to achieve the stability and firmness of the cage system, increase the strength, and increase the air flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

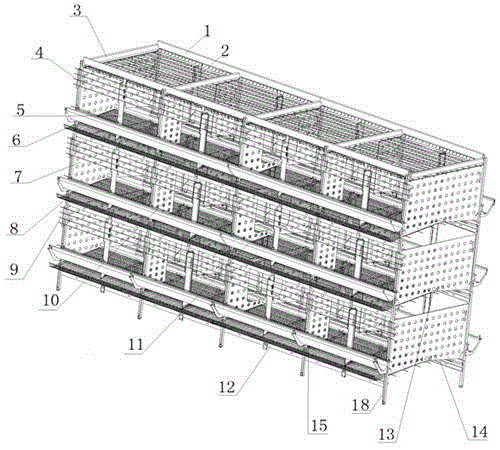

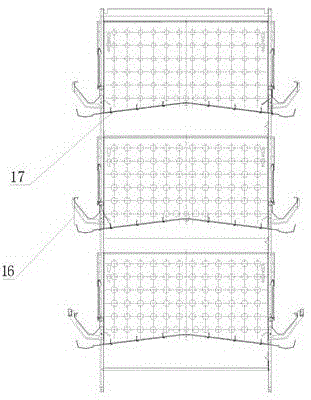

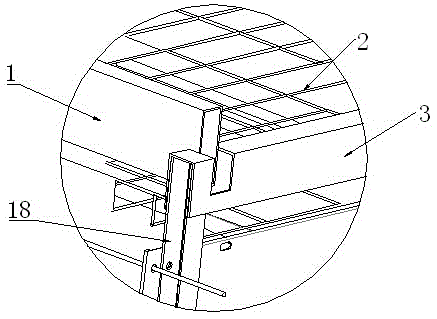

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the cage frame system of the self-crossing cage is composed of a support 18, a top floor partition 4, a middle and lower floor partition 7, and a bottom net 6 to form a multi-layer integral skeleton, and the top of the support 18 is fixedly connected with a driving track fixed support 3, The two ends of the fixed support 3 of the driving track are provided with a driving track support 1, and the front and rear sides of the support 18 of each layer are provided with a material trough 8 and a large door net line 9. The top net 2, the bottom net 6 of each layer is provided with a bracket side plate 12, the bottom ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com