General glue spraying conveyer line

A conveyor line, general-purpose technology, applied in the direction of conveyors, injection devices, transportation and packaging, etc., can solve the problem of low commonality, and achieve the effect of strong versatility, high reliability, easy installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

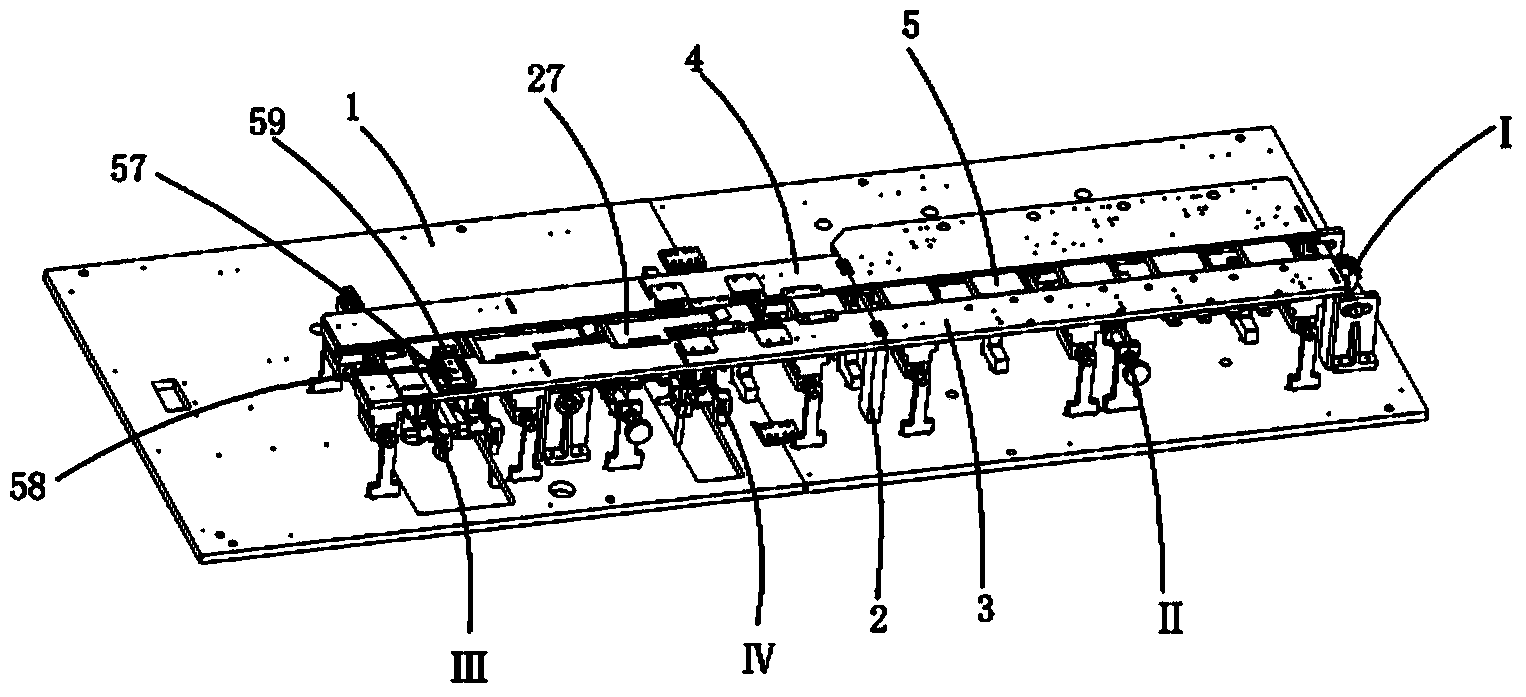

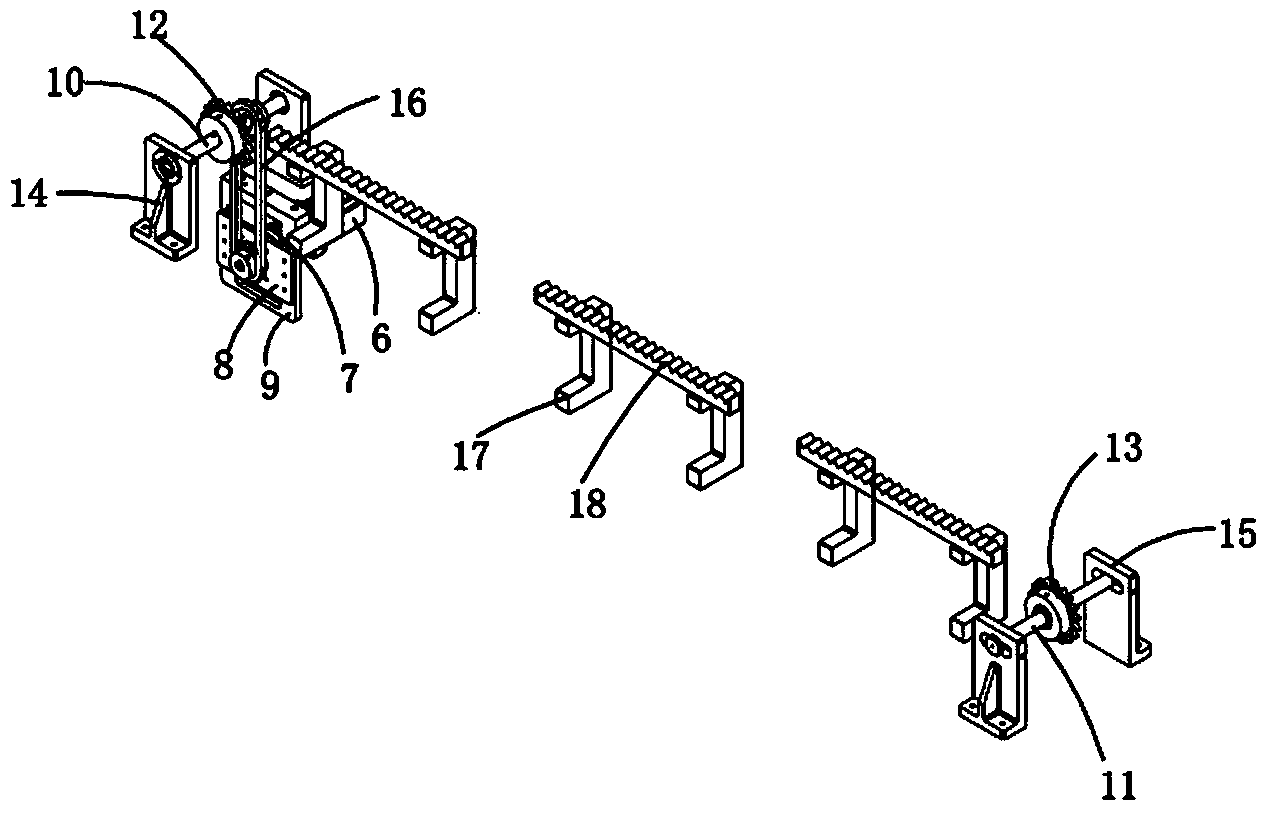

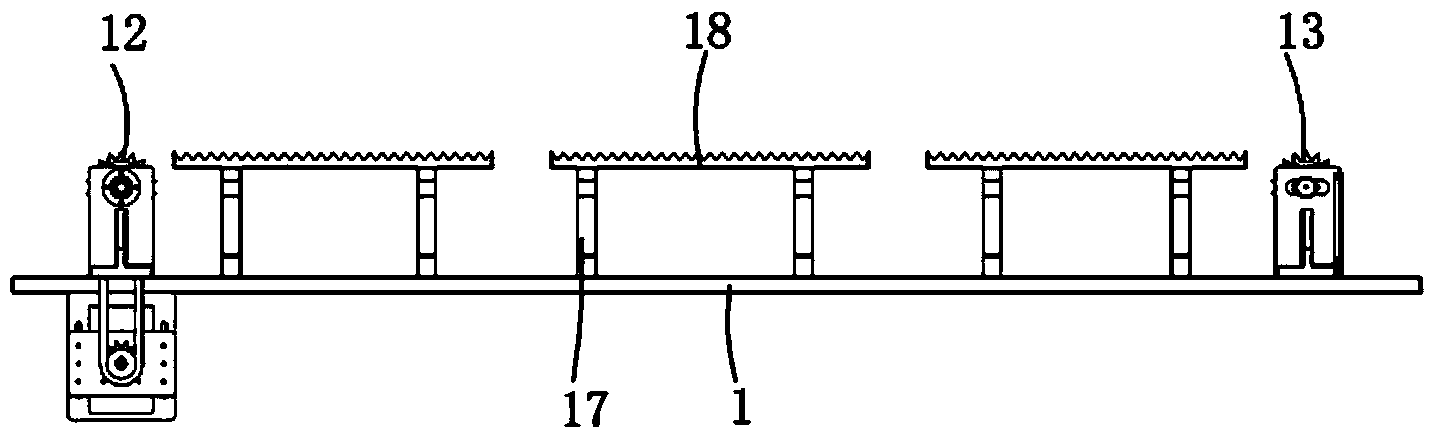

[0041] Examples, see attached Figure 1-8 , a general-purpose glue spraying conveying line, which includes a bottom plate 1, on which front and rear adjustment plates 3 and 4 are installed through a support plate 2, and a product 5 is placed between the front and rear adjustment plates, and the front and rear adjustment There are slot holes on the board respectively, and installation holes are provided on the support board, the front and rear support boards can be fixed under the adjustment board through the slot holes and installation holes, and the support function of the support board can ensure that the adjustment board is more stable during the moving process. Stable; the bottom plate is also equipped with conveyor line device I, conveyor line width adjustment device II, longitudinal glue spraying mechanism III and horizontal glue spraying mechanism IV, the conveyor line device can transport products forward, and the conveyor line width adjustment The device can adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com