A monitoring circuit of supersonic flame spraying control system

A supersonic flame and control system technology, which is applied in coating, molten spraying, metal material coating process, etc., can solve problems such as difficulty in ensuring flexible gas control, excessive solenoid valve, and unfavorable gas raw material supply, etc. To achieve the effect of convenient and clear observation, easy misoperation, and humanized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

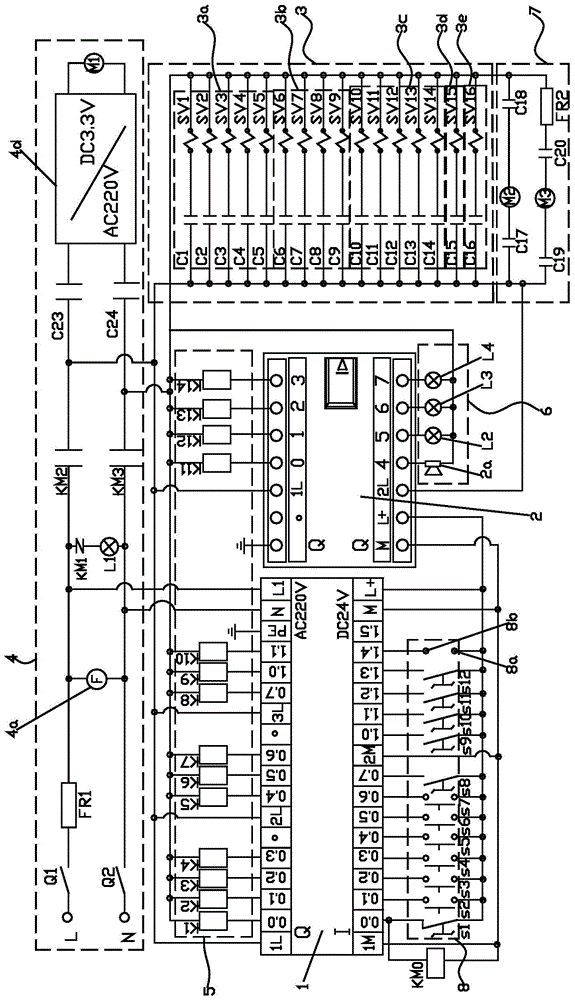

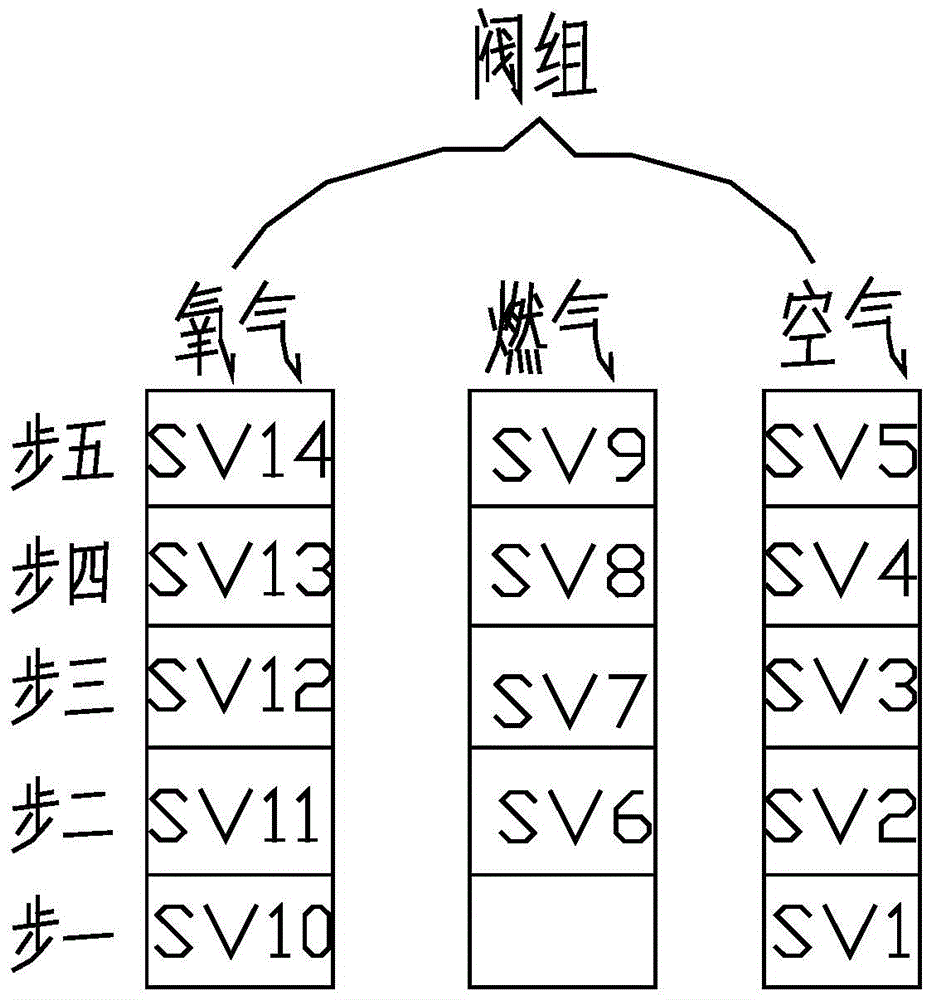

[0033] Such as figure 1 , figure 2 As shown, a monitoring circuit of a supersonic flame spraying control system includes a programmable logic controller 1, a digital input and output module 2, a main line circuit 4, a weak current terminal group 5, a strong current terminal group 3, an alarm module 6, Motor execution module 7 and switch group 8 .

[0034] The main wire circuit 4 has live wire, neutral wire and rectifier 4d, and the live wire switch Q1, the first current-limiting protector FR1, the second emergency stop relay strong current terminal KM2 and the twenty-third relay strong current are sequentially arranged on the fire wire. Electric terminal C23, the neutral line is provided with zero line switch Q2, the third emergency stop rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com