Supersonic flame spraying system

A technology of supersonic flame and spraying gun, which is applied in coating, fusion spraying, metal material coating process, etc., and can solve the problems of high spraying cost, large oxygen consumption, and affecting coating quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

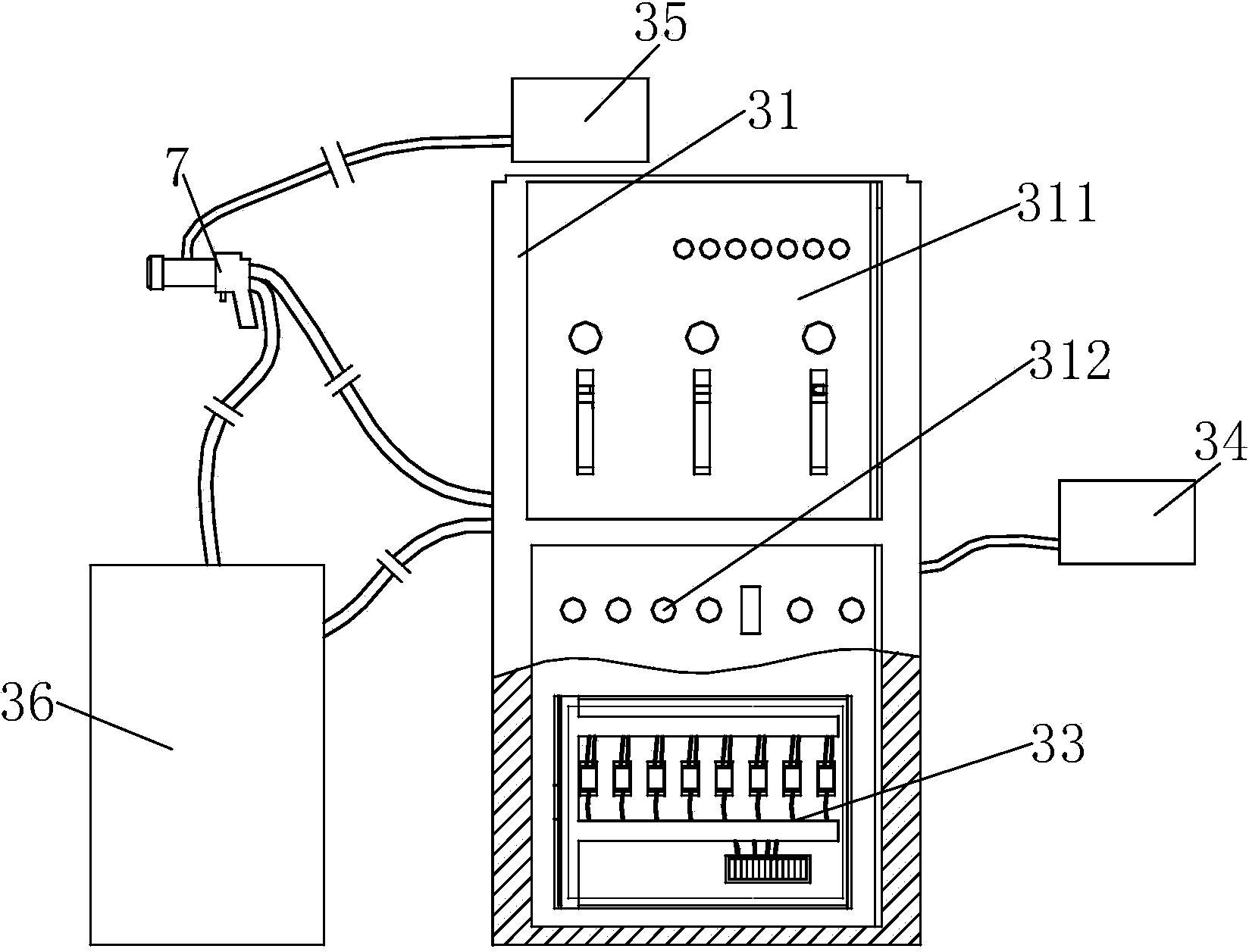

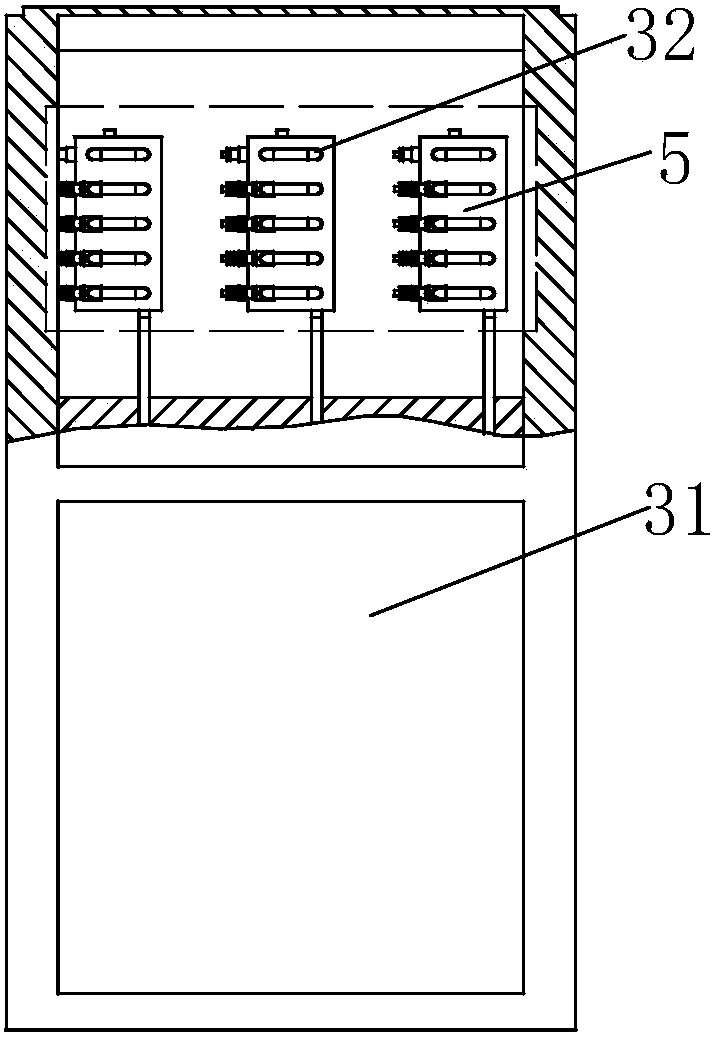

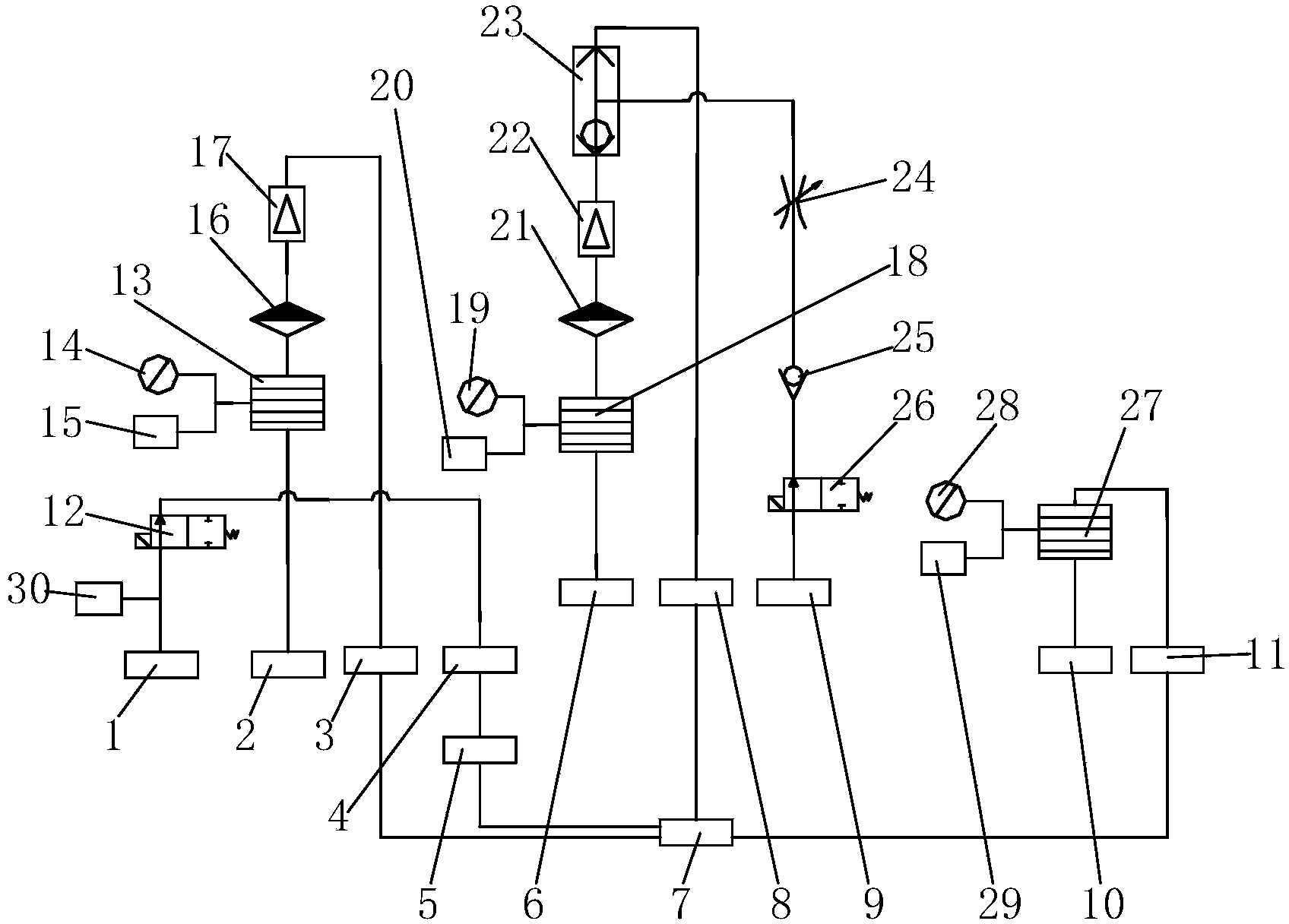

[0046] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a supersonic flame spraying system includes a control cabinet 31, an execution system 32, a control circuit 33, a tank group 34, a chiller 35, a powder feeder 36 and a spray gun 7, and the upper side of the front end of the control cabinet 31 is A display interface 311 is provided at the position, and a control interface 312 is provided at the lower side of the front end of the control cabinet 31; the execution system 32 is located above the interior of the control cabinet 31, and the control circuit 33 is located below the interior of the control cabinet 31; The tank group 34 is connected to the execution system 32 through pipelines, the chiller 35 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com