Torsional vibration fatigue life loss estimation method and system for generator unit shaft system-vanes

A technology for shafting torsional vibration and generator sets, which is used in engine testing, machine/structural component testing, measuring devices, etc., and can solve problems such as shafting lengthening, shafting and blade fatigue, fatigue cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings.

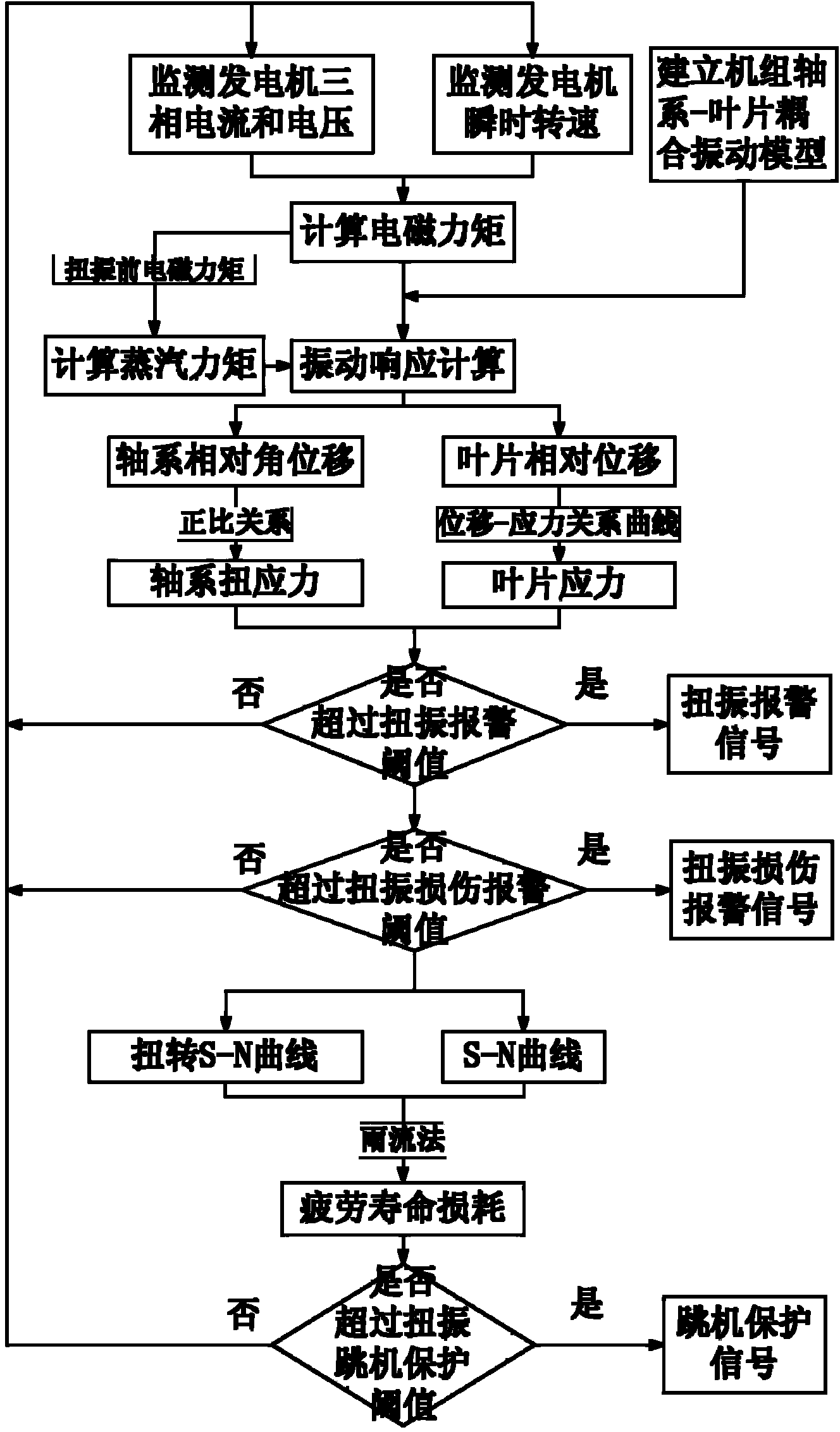

[0103] A method for evaluating the fatigue life loss of shafting-blade torsional vibration of generator sets, such as figure 1 shown, including:

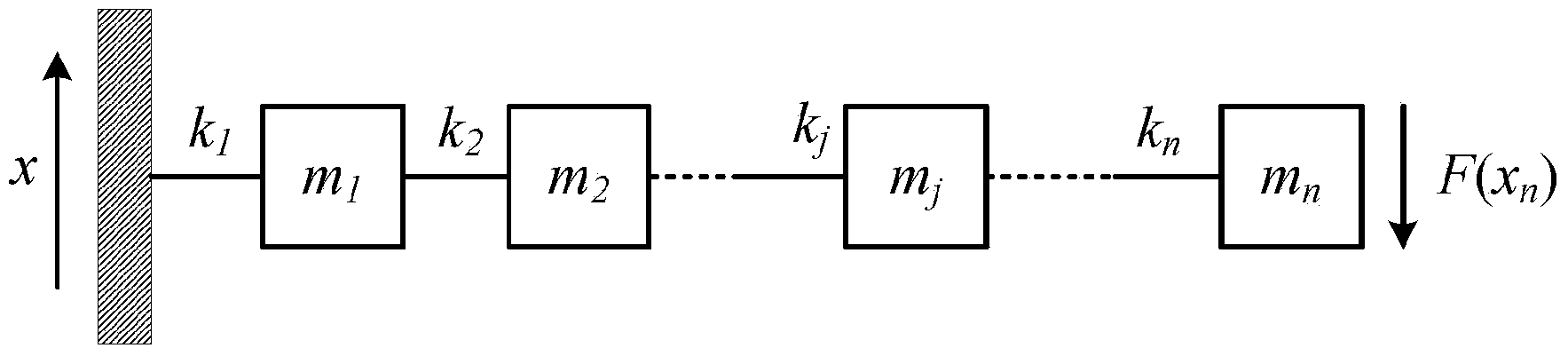

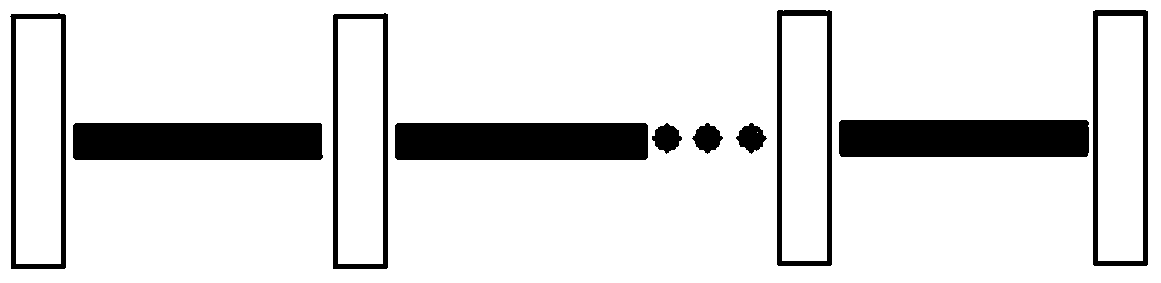

[0104] Step 1. According to the actual structure of the generator set shaft-blade, establish the shaft-blade coupling vibration model of the generator set;

[0105] Step 2. Real-time monitoring of generator three-phase current, voltage and speed, calculation of generator electromagnetic torque and steam turbine steam torque;

[0106] Step 3. Calculate the vibration response based on the shafting-blade coupling vibration model, and calculate the relative displacement between the mass blocks in the model;

[0107] Step 4, calculating the torsional stress response of the shafting dangerous section and the stress response of the blade dangerous point;

[0108] Step 5. Determine whether the torsional stress of the danger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com