Optical lens assembly

An optical lens and component technology, applied in optical components, optics, installation, etc., can solve problems such as lens stability limitations, large aberration, and failure to meet requirements, and achieve low product yield, large depth of field, and module height. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

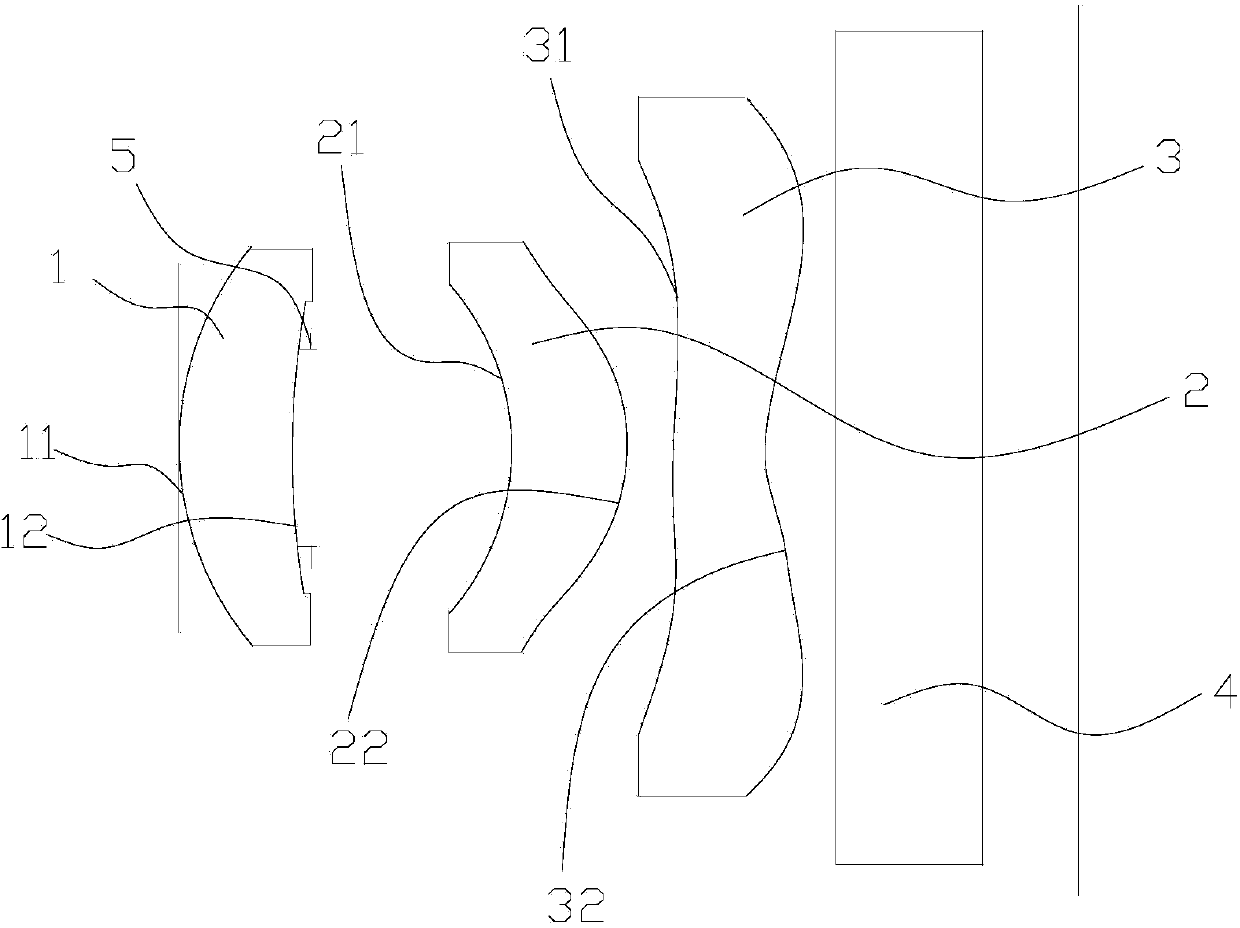

[0030] refer to figure 1 , the optical lens assembly of the present invention is an aspheric mobile phone lens, which includes a first lens 1, a second lens 2, a third lens 3, and a filter 4 arranged in sequence from the object side to the imaging side And the diaphragm 5, the diaphragm 5 is arranged on the side of the first lens 1 on the side of the first lens 1 near the imaging side, so that the diaphragm is placed in the middle.

[0031] The surface sequence 11 of the first lens 1 on the object side has a positive radius of curvature and is a convex surface facing the object side, the surface sequence 12 on the imaging side has a positive radius of curvature and the outer ring is a plane, and the middle part is a concave surface with an opening facing the image side; The surface sequence 21 of the second lens 2 on the object side has a negative radius of curvature, the outer ring is a plane, and the middle part is a concave surface with an opening facing the object side, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com