Fluid distributor

A fluid distributor and flow channel technology, applied in the field of fuel cells/flow batteries, can solve the problems of not being able to evenly distribute a gas, complex structure, difficult to replace, etc., and achieve the effects of simple structure, low cost, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

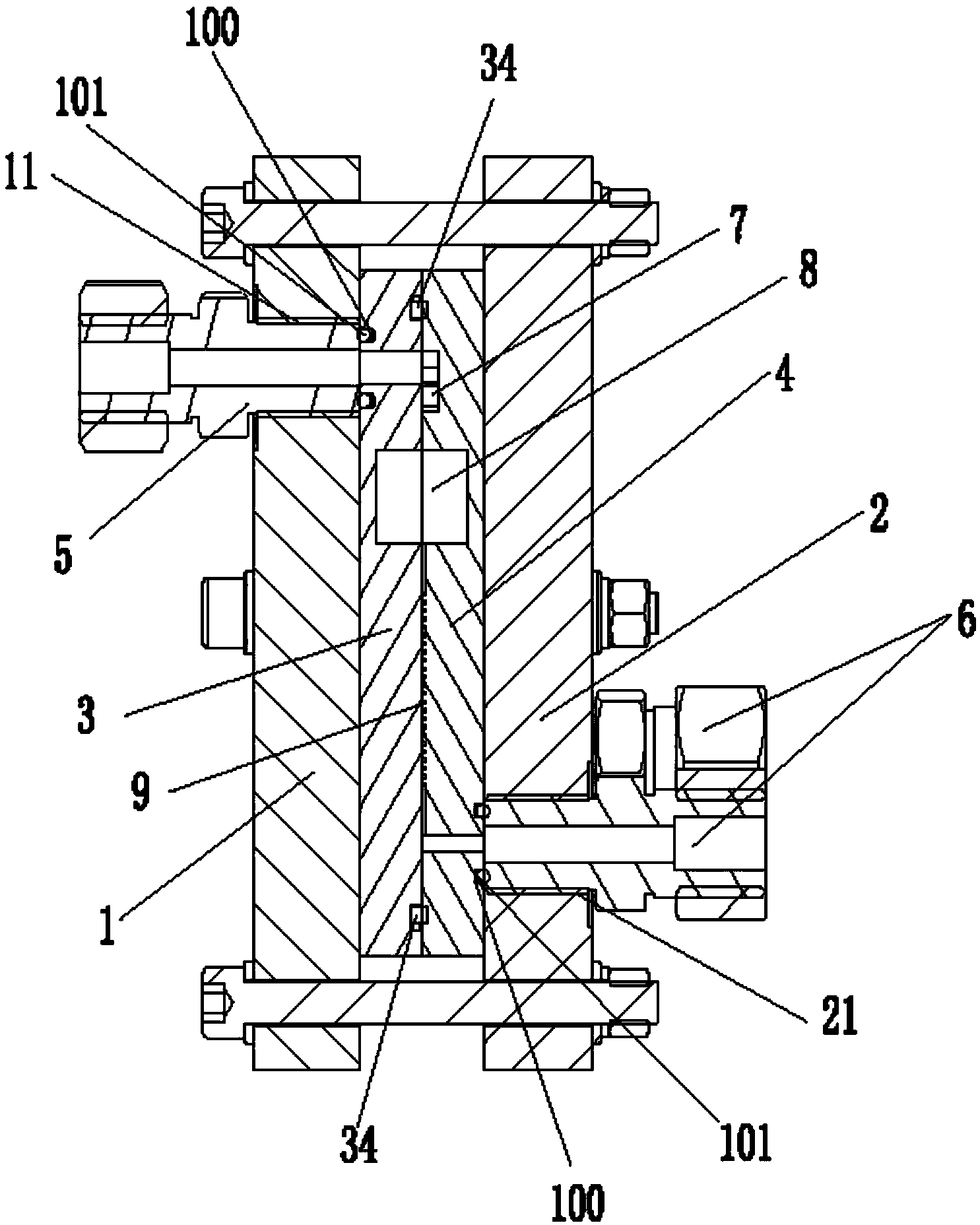

[0034] Embodiment one: if Figure 1 to Figure 5 shown.

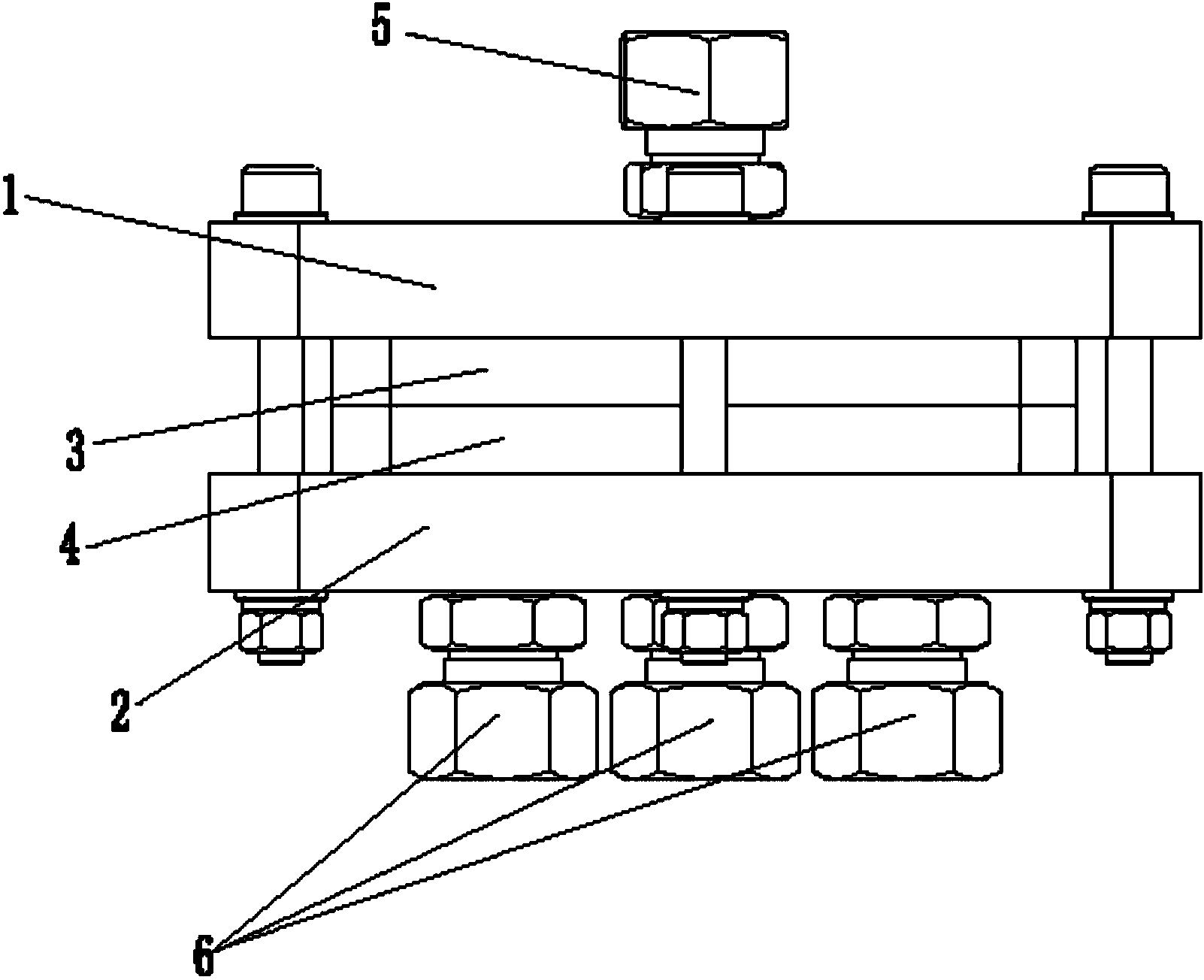

[0035] A fluid distributor, comprising an inlet end plate 1, an outlet end plate 2, a flow channel cover plate 3, a flow channel groove plate 4, an inlet joint 5 and several outlet joints 6,

[0036] An inlet joint hole 11 is opened on the inlet end plate 1, and the inlet joint hole 11 matches the inlet joint 5, and the inlet joint 5 is fixedly arranged in the inlet joint hole 11;

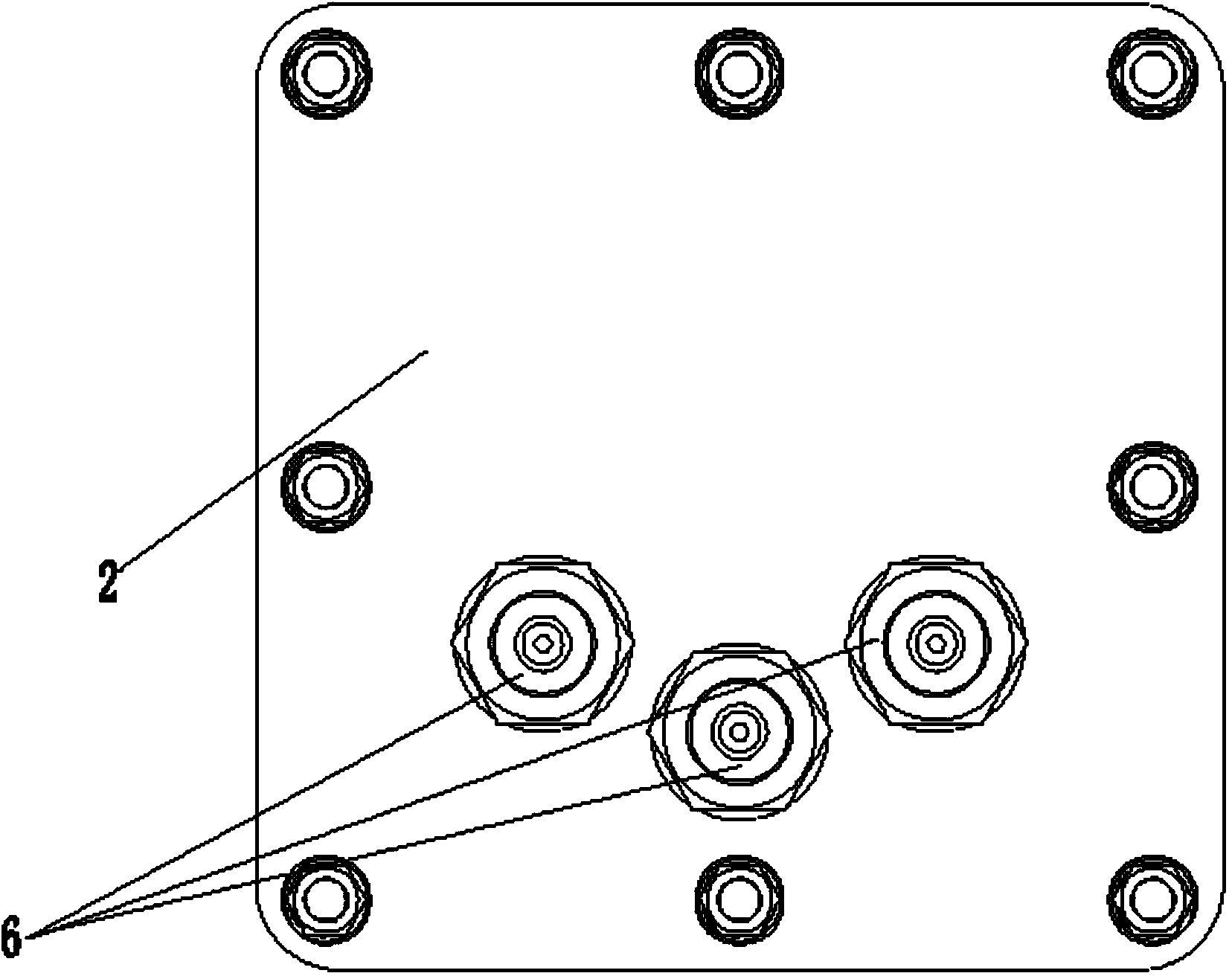

[0037] Several outlet joint holes 21 are opened on the outlet end plate 2, and the outlet joint holes 21 are matched with the outlet joints 6, and several outlet joints 6 are fixedly arranged in several outlet joint holes 21;

[0038] An inlet hole 31 and a first equalizing groove 32 are opened on the runner cover plate 3;

[0039] The flow channel plate 4 is provided with a flow channel groove 41, a second flow equalization groove 42, a number of flow distribution structures and a number of outlet holes 44, the flow channel groove 41 is co...

Embodiment 2

[0067] Embodiment 2: as Figure 7 , Figure 8 shown.

[0068] Figure 7 , Figure 8 It is another embodiment of the fluid distributor of the present invention, which includes a base plate 61, a distribution block 62 and a bracket plate 63 fixedly arranged on the base plate 61, a sealing threaded hole 621 is arranged at one end of the distribution block 62, and the inlet joint 64 is arranged on Among the sealing threaded holes, several distributing holes 622 are arranged in the distributing block 62 .

[0069] One end of the joint 65 is connected to the distribution hole 622 in the distribution block 62, the other end is connected to the first transition capillary 66, the other end of the first transition capillary 66 is connected to the elongated capillary 67, and the other end of the elongated capillary 67 is connected to the second transition capillary 68 , the other end of the second transitional capillary 68 is connected to the over-wall joint 69 , and the over-wall jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com